Ah. K. Just didn’t want you getting screwed over since you implied that timing was important.

The prices you quoted were USD or loonies?

Ah. K. Just didn’t want you getting screwed over since you implied that timing was important.

The prices you quoted were USD or loonies?

Prices I mentioned are CAD

Do you get good quality engravings with the 2 phase rotary?

Mine is 3 phase

I have a PiBurn.

Might want to ensure your acceleration and speeds have been slowed down on the rotary axis.

Good luck…

You mean I should change the parameters to slow them down? Do you have a suggestion for me.?I would imagine you mean on the Y because that’s the axis my rotary is running on

Thats looks like a really good system. Might be a worthy investment for me since that’s literally all I’ll be doing on the machine. Just not sure if they support 2-phase. I’ll give it a little read

Mine is 2 phase. I believe there is an option for for the type of motor.

I watched lots of videos and hopefully did my research and the are lots of areas that are not intuitively obvious that become issues.

Some have no rubber on the driving wheel to help with traction.

No way to press down on the object to help with maintaining traction.

The mugs and cups will ‘walk’, left and right, without some way to keep them from it.

Some won’t allow a cup with a handle, like a coffee cup.

Most won’t allow a large 64 oz tumbler, which I think will fit on the PiBurn.

I think mine was $728, pretty expensive, also have the magnetic feet. I got the one that appeared to have addressed most of the issues I had found.

Start with values in around 5. The ‘Start Speed’ is what speed it ‘starts’ rotating, so keep it low along with the acceleration values. I’m still fooling with these and I don’t remember what they are set to, but they are pretty low. I’ll be doing some mugs before Friday and I’ll try and remember to check them when I get the configuration loaded for the rotary.

Good luck

![]()

Ok thank you.

Did you ever do something?

Is there any way to change the parameter to when the laser starts shooting coming over the engraving?

My machine is in parts right now. Probably be mid week. I’ll try and fire up the Ruida when I get up in the morning and see if I can see anything…

It’s ok, I ordered the PiBurn. Because I am 98% sure that is the problem. It engraved perfectly when doing flat. And I’ve tried every parameter combination under the sun and nothing makes a difference

I didn’t do anything ‘wizardry’ like. Just slowed anything that moved the rotary axis down as slow as possible. Sometimes it’s almost intolerable.

Keep in mind the machine needs to slow and speed up to do any work. If the acceleration is slow it takes more time. It’s also imparts speed problems when setting the speed. You may ask for a max value, but in reality it may not have the room to move the object fast enough to maintain any speed.

I think you’ll like the PiBurn. I’ve really enjoyed mine. It is another mechanical ‘think’ to deal with…

I had to put mine in with the motor to the left, until I switched out the wiring. If your image is flipped, try swapping ends of the rotary. I just swapped the connections on my PiBurn plug when I got around to it…

Good luck… I’ll check out the Ruida tomorrow, but can’t think of any thing off hand…

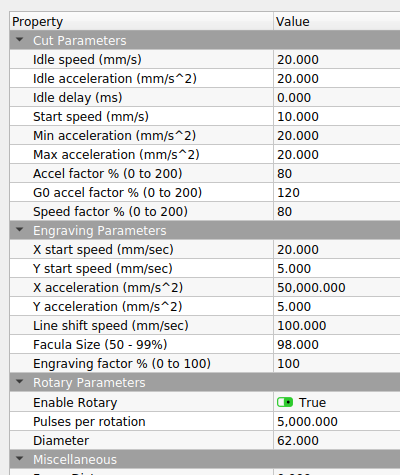

This is the current configuration. You will, no doubt, have to tweak them to fit your project. I’m still fiddling with mine…

The only one I’m still concerned about is the Y engraving Max. I have it at 500mm/s which, if needed, is too big. I haven’t used any speeds that fast, so I’m still wondering if there is an advantage to drop it lower. It’s not a race against time, at least in my operation.

The cut max acceleration may be modified also. I sometimes lower it to 5mm/s^2.

Only use values that pertain to the rotary, i.e. the Y axis values. Some of the others may not work too well on some machines.

Good luck, keep us informed

Wow that X acceleration is high. Doesn’t your machine fall apart? If I set mine to 20 it runs so fast it actually shakes.

Thanks for your time and info by the way. I’ve been working with the company for a week and we’re pretty much the sure it’s the rotary. There’s, on a video comparison, is much smoother than mine.

Slightly modified…

Hence the warnings not to use anything other than the Y axes information…

With the PiBurn

Dash… Kind of dark, fired it up to read off the current rotary values.

That 50,000mm/s^2 acceleration is probably a little to high. It seems more happy with about 45,000. The upper speed is set to 1650mm/s for the X axes, since I’ve dropped a lot of mass from the head.

I got the Cloudray rotary today, that I ordered a week ago, and the results are perfect. The only issues you can see come from the tape and the previous engravings underneath

Looks great…

Good luck, take care

You as well man. Thanks for your time.

TTYL