Hi. I own an OmTech 50w co2 laser. Recently i noticed that when i try to cur 3mm plywood with more power( 45%-8mm/sec up to 80%-8mm/sec) it doesn’t cut. I thought my tube starts to fail. I searched in my controller and i have used the laser for 75 hours(i have it almost a year). So i tried 25%-8mm/sec and cut through easily. The input power is correct as i checked it matches the amps which i can see at a display on my laser power supply. Does someone has any clue what is going on? Am i missing something? Thanks in advance!!!

Things I’ve noticed.

- Every piece of wood is different and will cut differently.

- Check the lens and mirrors are clean

- Check beam alignment

What is your minimum power?

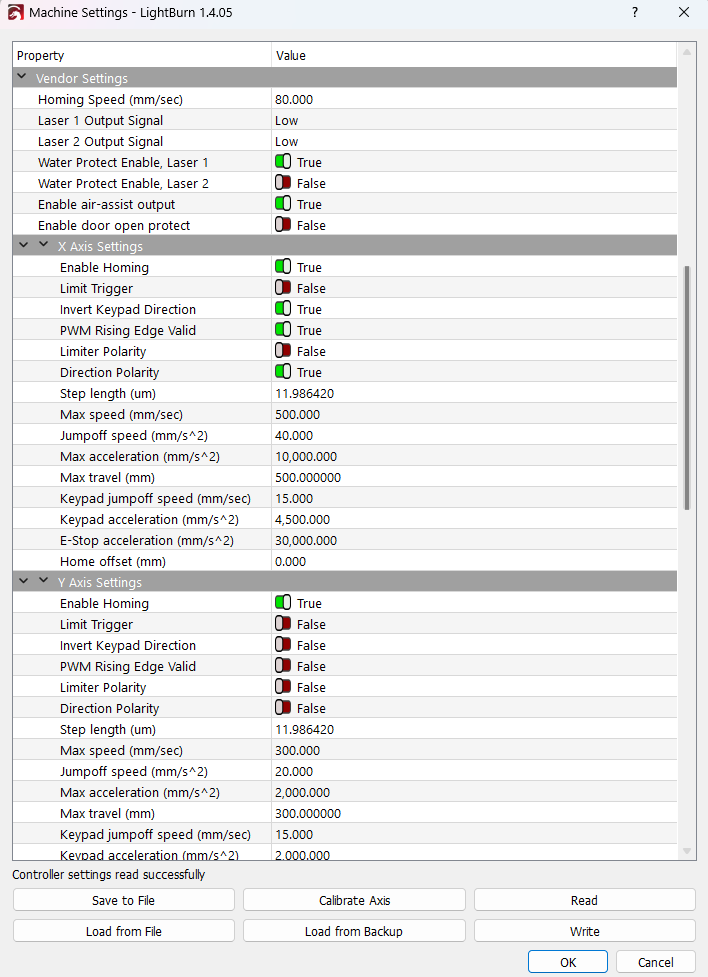

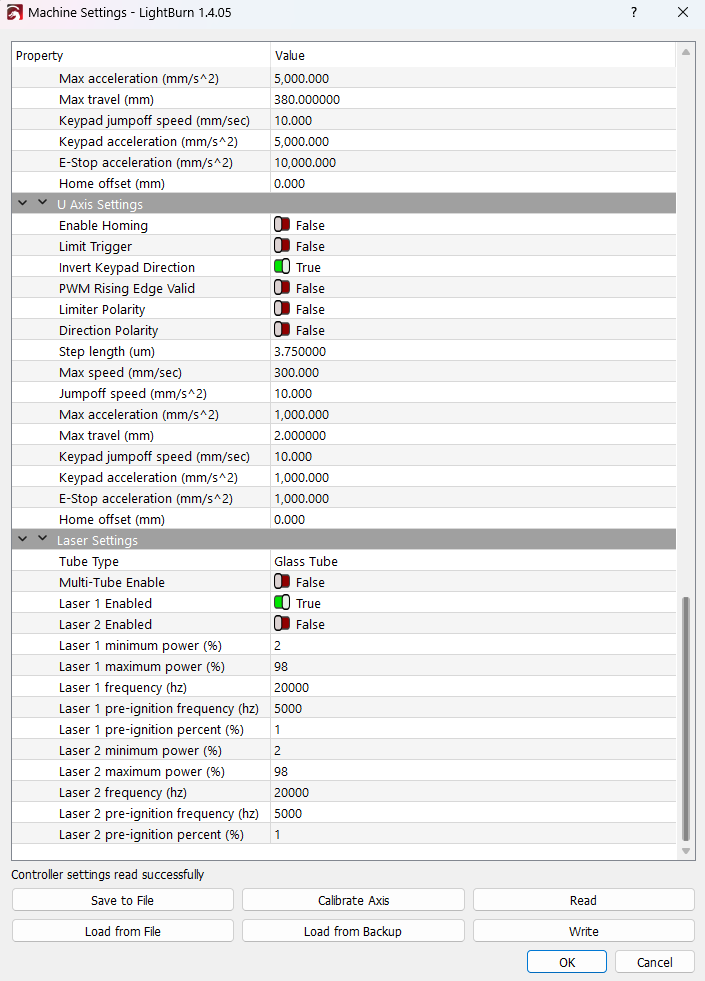

All the above are at the same piece of wood(3mm plywood). The lens and mirrors are pretty clean. The beam alignment is fine. From lightburn machine settings the minimum power is 2% and maximum 98%.

What is your start speed?

What is your layers minimum/maximum power settings?

![]()

The same for 80%. I noticed this because i cut with 45%-8mm/sec and didn’t cut through in many points but i could see the cutting lines from the back of the wood. So i put 80%-8mm/sec and i wasn’t able to see anything from the back of the wood. It didn’t cut at all.

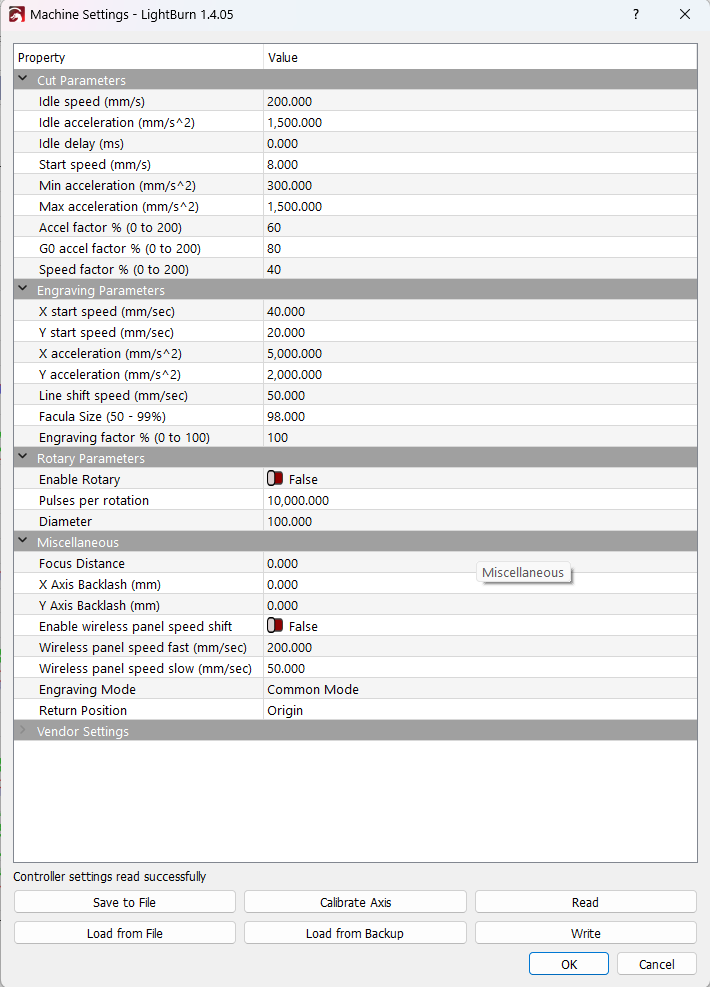

This is the power and current of my laser and it matches with what i put in the laser. E.g when i tried 80% i saw the current between 23 and 25mA.

If your machine doesn’t “fail something”, it would be a good idea to do a solid old-fashioned material test. The best will be if you can find some “neutral” material, such as MDF, preferably some scraps you have left over from once you were able to cut it with the machine. You should preferably avoid plywood you “don’t know”. I have some plywood sheets lying around here with a “bad to cut” sticker. Probably special impregnated outdoor plywood - not very thick but almost impossible to get through with my 60 Watt laser.

I get the best test results with thick acrylic, I have some old tests, I compare them with the current tests. As I said, very visually clear results, unfortunately not everyone has thick acrylic lying around.

These are a good guideline for maximum current for a specific length or size of tube. If you are running >20 mA through the tube, that is not good.

I have a 50W China Blue, and it puts out about 40W… it’s 880mm in length…

Do you have a voltmeter?

![]()

I never run my laser above 45% but i wanted to try with 80 to see if i cut the piece but the cut didn’t even got yhrough the wood. Yes i have a voltmeter.

- properly working tube

- clean and aligned optics

- proper focus

If you have these three, they work.

The next is to do a TEM00 mode check…

Which machine exactly do you have? A link is great…

Sounds like a relatively new machine, is it?

![]()

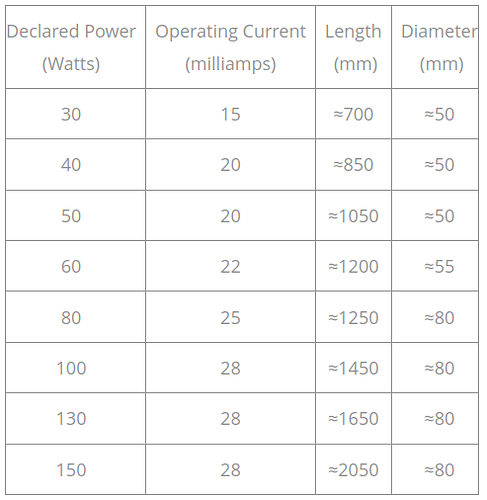

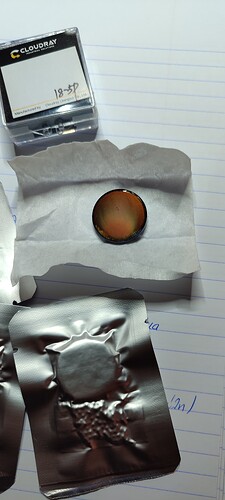

Finally the problem was the 3rd mirror(the one above the laser head). I had recently changed the one that came with the laser(for no reason, just so…) with one from cloudray. The first was MOLYBDENUM and the cloudray one was silicon. I don’t know why it failed and from inspection with a light without taking out was ok. Besides it was the new one…It was my fault that i checked everything else than the obvious. After i put the original MOLYBDENUM mirror it’s just fine.

Previous cuts and after i changed the mirror(same piece of wood). I aslo have 2 more cloudray mirrors but i don’t feel confident after that to use them.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.