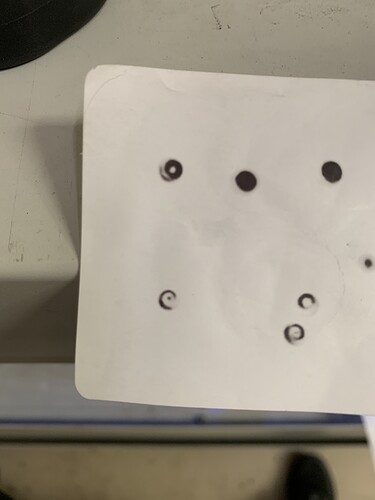

Are there any indicators that might point to the need for these to be adjusted? I ask because I’m getting an odd beam pattern when I’m pulsing at low power closest to the emitter. I’m not sure if this is common or not. If you look at the attached image you can see what I’m talking about. When within 50cm of the emitter end or so I get a crescent or “O” shaped beam but it moves to a more defined point as pulse farther away… say 70cm + from the end of the emitter. I use thermal paper and set my max power to 11% to pulse. This is for a 168cm tube rated 130w continuous 170w peak.