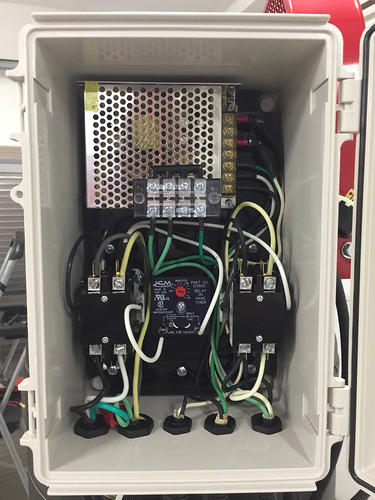

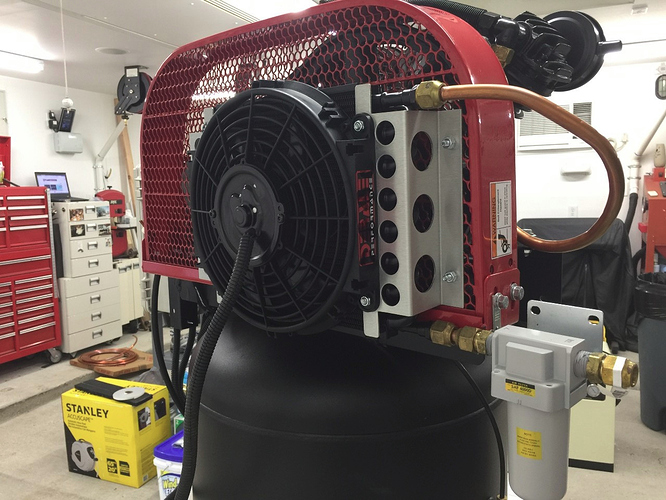

Behind the building is the garden shed with my air compressor. I designed and built the controller for my new compressed air system which incorporates a delay panel so when the pressure switch engages, the air dryer and aftercooler fan start. Then 45 seconds later the compressor turns on. This allows the air dryer to chill down for the recovery cycle and prevents me from having to keep the unit constantly running. (I used my laser cutter to make the mounting panel for the components in the controller box.)

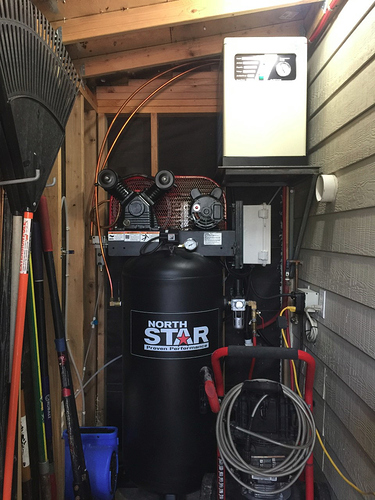

On the lower half of the wall of my garden shed are two gable vents for fresh air intake while on the roof is a vent. I installed a blower (in the picture) just below the compressor. It automatically comes on with the air dryer and pulls in outside air from the vent into the shed (to help keep the heat buildup down).

I also have in here the vac head for the central vac system I plumbed in to the workspace.