This was asked before but I found no solutions posted.

I’m new to laser engraving and cutting. I have an AtomStack A5 Pro. I started off using LaserGRBL and after several trial and errors I finally started getting good results. I then started a project to engrave features then cut out the work. I did this using two JPEG images, one for engraving, the other for cutting. I did experienced a slight offset by doing this.

I eventually purchased a copy of LightBurn, given that it has illustrator like features and layers. This, and other functions, makes makes creating my projects much easier and faster.

The problem I’m experiencing is how long it takes to engrave, then cut, a project.

With LaserGRBL it took about 8 hours to engrave, and then cut my project. With LightBurn it’s taking me about 13 hours for a very similar project. This is after changing the power and speed settings, basically increasing the power, compared to what I used on LaserGRBL, and slowing down the speed. I had to do this with both engraving and cutting.

Question: besides the obvious settings available are there internal settings, within the software, that adjusts the power of the laser diode’s intensity?

I know how to adjust both power and speed on both LaserGRBL and LightBurn but I find it hard to believe that the settings have to be so very different.

At this point I’m tempted to figure out my off set problem with using the two JPEGs and go back to LaserGRBL. At least it takes less time to complete a project.

Thank you for any help you can provide.

How are you cutting with the JPEG image? Are you just forcefully burning through?

What’s the variance for the exact same project? Similar may not be similar enough when trying to determine like-for-like behavior.

The controller in the machine ultimately defines the power. The software used to communicate with the controller, in this case LightBurn, simply requests the controller for a specific power level. The controller interprets the rest.

If you’re working with jpeg images the main factors that would impact job time for a given laser include:

- image mode

- line interval size

- overall dimensions

- speed setting for layer

Can you upload a .lbrn sample file and an indication of how long it’s taking you to run the file?

How are you cutting with the JPEG image? Are you just forcefully burning through?

In LaserGRBL you can vectorise the image, similar to ‘Trace’ in LightBurn.

What’s the variance for the exact same project? Similar may not be similar enough when trying to determine like-for-like behavior.

Both projects are very similar. Both have panels that are 180 x 80mm in size, for 3mm thick plywood. Profiles of the panels are slightly different. Engraving on both are simple, but are a little different. I can understand time differences between the two projects, but not five hours! I’ve not tried the first project on LightBurn, nor the second project on LaserGRBL.

If you’re working with jpeg images the main factors that would impact job time for a given laser include:

- image mode.

I’m not sure what you mean by image mode. In LaserGRBL jpeg images are imported. In LightBurn a DXF of the panel outline is imported, then a jpeg of the engraving is imported then traced. - line interval size.

In LaserGRBL I’ve increased the line to line quality, which would reduce the speed some. In LightBurn I’ve not changed the default settings. - overall dimensions.

Both project’s overall dimensions are identical. - speed setting for layer

In LaserGRBL, engraving, speed was set to 2500 mm/min, power 30%. 1 pass. In LightBurn, 1200 mm/min, power 80%, 2 passes. The quality of the engraving with LaserGRBL is much better than with LightBurn.

LaserGRBL, cut, 120 mm/min, power 80%, 2 passes. LightBurn, 100 mm/min, power 100%. Passes set to 4. I’m currently redoing a project so I don’t know if I’ll need more passes until it’s finished. First attempt on this project 2 passes were set. Did not cut through.

Can you upload a .lbrn sample file and an indication of how long it’s taking you to run the file?

I’m currently running a job, which is to run 13 hours in total. If I did this project using LaserGRBL it would take approximately 8 hours.

Method used in creating my project, a candle holder using four panels 180 x 80mm in size.

Create 3D CAD model in SolidWorks. Export as DXF file. Import into Adobe Illustrator. This is for cutting the outline. Import jpeg image into Illustrator to use for engraving. Aline both then group. Duplicate to create four exact panels then arrange to fit within the size of the plywood to be used. place outline images in one layer, the images for engraving in another layer. Create an overall outline around the work. This will define the size of the jpeg images when exported from Illustrator. One jpeg image for cutting, turning off layer with engraving image. The other jpeg for engraving, turning off layer with outline image.

Of course this process takes longer than just using LightBurn.

Got you. If vectorized the jpeg ancestry isn’t so much the important pieces of this. Is there a reason you’re not importing a vector shape directly?

What specific values are you using?

You’re confusing me a bit here. You have fundamentally different settings. Is there a reason why you’d expect performance to be the same?

You’re confusing me a bit here. You have fundamentally different settings. Is there a reason why you’d expect performance to be the same?

I’m trying to get the same results from LightBurn as I got from LaserGRBL. That is a cut panel with engravings. So, to get the same results I had to use very different settings.

What I’m getting from your questions is LightBurn is far more complicated to use, and far less efficient, compared to LaserGRBL, and to get what I want, and much faster than using LightBurn, I’m better off continuing to use LaserGRBL .

It’s perfectly obvious to me that LightBurn is far too sophisticated for me, and it takes much less time to get a good quality result from LaserGRBL than using LightBurn. I guess the next best thing for me to do is to see if I can get my money back for the software.

I just realised I’m wasting my time here.

This is a fundamentally different question than how I perceived the original post. Whether that’s from how it was described or my interpretation is unsure but I’m reacting from this:

So it sounds like you’re saying you’re not able to get similar outcomes in LightBurn and this isn’t so much about speed. This changes the dialogue considerably.

Please provide the following:

- Photo samples of what you’re comparing from LaserGRBL and LightBurn. Again, this is much better done with the exact same image otherwise you’re dealing with many other factors

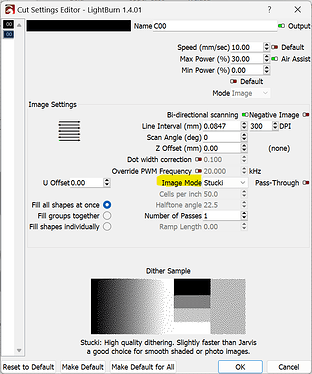

- Screenshots of the full settings you’re using for LaserGRBL and LightBurn

- Screenshot of Edit->Device Settings

- You should confirm that you’re getting like for like performance of the laser itself before focusing on the actual cut setting. If you run the same material test on both programs do you get identical results? If so, that only leaves the actual image processing as the variable. If not, you may have a different setup issue at play

Did you use the Trial license to test the machine?

That’s your call. But understand that if it’s not obvious what the specific issue is and the desired outcome then responses may not directly address what you’re actually trying to achieve.

The problem I see with this project:

JPEG (Raster graphic) are very slow to engrave. The same thing can be done much faster by using the TRACE function to create a Saleable Vector Graphic which can be manipulated to easily skip the non-cut area (or white space).

By adjusting the SVG engraving parameters, you can be able to shave off more than 60% of your run times.

Lighburn Software is very flexible - but it takes a little while to get comfortable with it.

If @Miguelmn1 would post up his .lbrn file for the forum to look at, there is a significant opportunity for the group to help him realize great results. @berainlb has helped my several times - he is a great resource for learning.

In LightBurn I imported the DXF of the panel’s outline. I then imported the jpeg of the image to be engraved. Afterwards I TRACED that image, then deleted the jpeg image. I then moved the trace to another layer. Used the fill setting and set the speed and power.

In LaserGRBL I imported two jpeg images, one for engraving, the other for cutting out the outline. It took about 7 hours to complete the laser project.

If I had continued with LightBurn it would have taken 13 hours to complete.

It seems to me that I’m getting more power output from the laser when using LaserGRBL. With LightBurn it seems as though I’m getting less power from the laser diode. Thus, high power settings, slow speed, for both engraving and cutting. I think there must be a setting wrong within LightBurn. Given that I’m new to laser cutting and LightBurn I have no clue where to look.

How do you know the time it takes to run?

The problems you are seeing have to be configuration issues, not the software of the hardware…

Both software products do the same things when it comes to running the job… so you should double check the configuration in Lightburn

I don’t think using different files is a good idea if you want a comparison. Run the same file with the same settings if you want to compare them.

Lightburn isn’t considered the best software because it doesn’t work correctly. ![]()

![]()

@Miguelmn1 - I say again - POST YOUR FILE here and we can compare actual results from professional and semi-pro users. The forum does not steal ideas from each other. We are here to help you - but we cannot look into a crystal ball to find out why you and only you are having this problem.

You have a User/config error and it’s not a software problem.

If you are going by estimated time in Preview window, if your setting were not read from your controller board, that estimate can be wildly out.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.