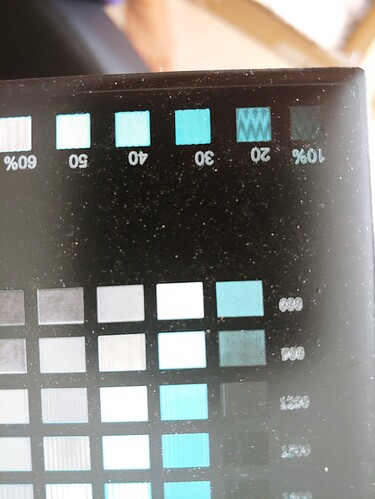

Hi, when I fill rectangles for test grids the corners are usually crisp but the interior fill is “wavy” like an oscillating pattern. What influences the creation of this pattern? I sometimes also see it in images. Is there a method to reduce such waves?

Slow down and secure the base from vibration.

It seems to be how Lightburn translates the image to the laser though. For example, I’ve been currently trying to figure out a horizontal banding problem so I know the laser path is straight, but “wavy” artifacts that are well aligned but crosses several laser paths are still visible signifying they were processed in, like a strikethrough symbol of a W or $.

If that were true then others would have the same problem.

Can you show an example image?

Sounds like moiré patterns. Does your DPI setting natch the image.

Albeit, the image is image mode while the power test is fill mode so the sweep is different.

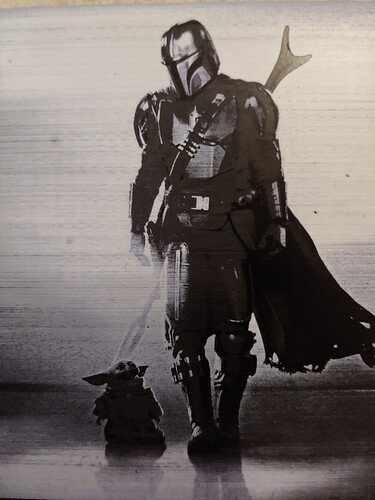

Hi, I am getting horizontal banding all of a sudden on my engravings. I tried different DPIs such as 363 DPI, different speeds, different pictures, bought new timer belts, etc… but still can’t figure out what’s causing these lines or how to fix them. I have Ortur Lasermaster 2 and images were perfect just last week. I notice that this is most obvious when using Grayscale, and less so with dither or jarvis, but the banding still occurs. Rather than the laser misfiring, it would almost seem like there is a gap between lines where the laser path is not “overlapping”, forming “grooves”. I can physically feel a banded texture, rather than the smooth surface of previous engravings.

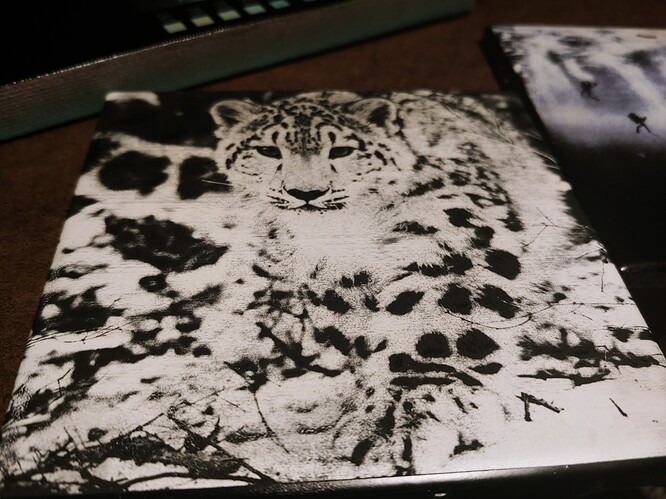

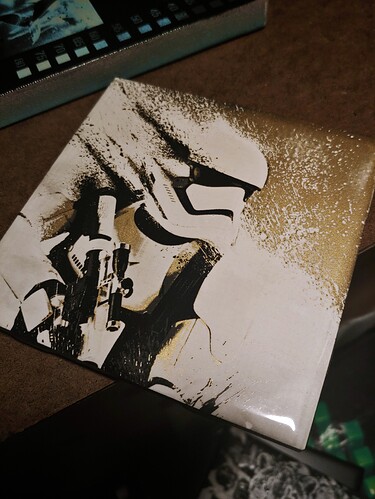

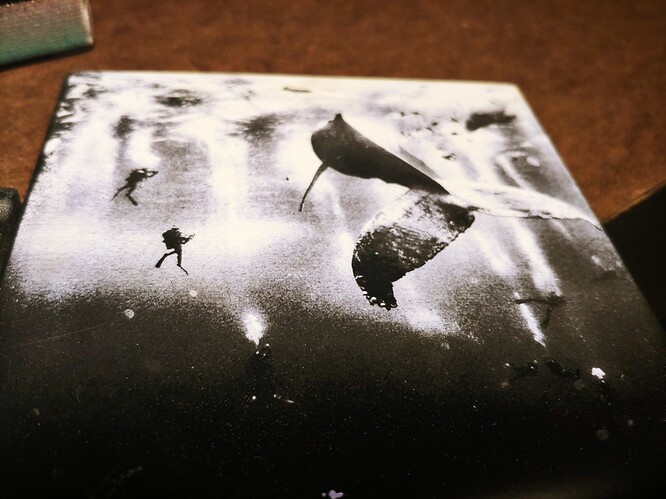

Banding can be seen on the snow leopard black and white too. The whale was probably the last picture done before this occurred. The Stormtrooper and Yoda was done about 2 weeks ago, and it had no banding.

It’s a shame with all the nice pictures you make, that you have these technical problems. I guess you’ve worn out 'your machine. A little too much slack in the bearings, belts … on the x axis?

Is the problem just as visible when you turn the image 90 degrees?

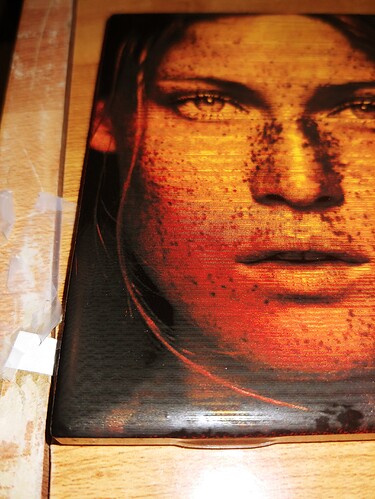

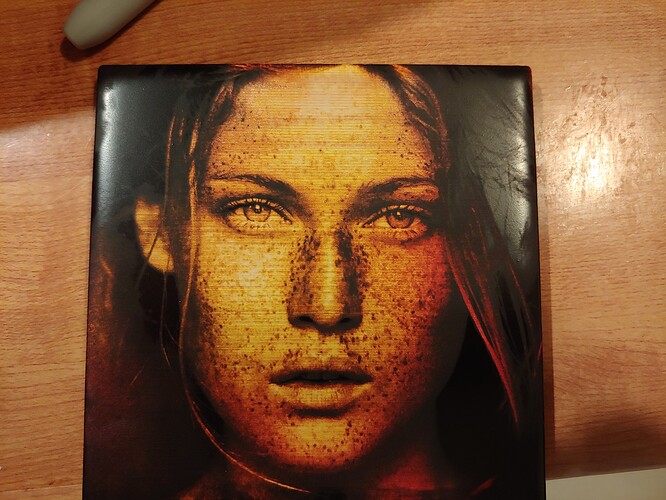

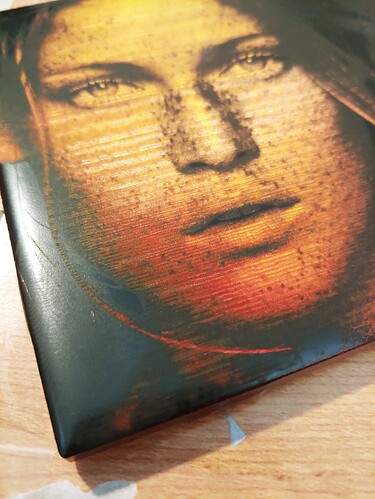

I got the machine about 2 months ago, built it roughly 1.5 months ago and used LightBurn trial for 30 days and bought it about 2 weeks ago. Relatively new machine. I thought it was the belt issue or DPI at first and frightened all belts. Didn’t help. I bought new belts a few days ago and still getting some, but less obvious banding. I’ve done the orange girl portrait once or twice every iteration and haven’t got the lines to disappear yet. 600 DPI and 363 DPI seem to have the banding, which shoots down my idea of expanding the beam path and making them overlap.

I tried different scan angles but it seems like they just occur on the horizontal axis only. Makes me think theres either something wrong with the Y axis motor/belt shaft, or program settings. I notice there’s a couple wavy fills at some parts of the images but could just be artifacts.

Of course, I mean the Y-axis, my mistake. But you are on the right track, if you change the image orientation or scan angle and still have the same problems, there is something wrong with the Y-axis. Even if you have a “new” machine and it says “Ortur” or “Eleksmaker”, it is still machines that come from a mass production in China, just like the K40, I have both. (I’ve had a small embedded “bump” on one of the small white plastic running rollers once !!)

Once you have found your spot size of your laser you should not go very much below this size when you engrave, it falsifies your “grayscale”, that is, you do not get the actual coloring of the material with a given energy if you run twice in the same track. But with your fine pictures, I think you know a lot more about engraving and setting a diode like I do, it’s just a little memory note.

Man, the lines are just getting worse and worse. I occasionally hear the motor go “krrrrrk” for no reason. It’s supposed to just scan back and forth and that sound doesn’t seem to match the back and forth motion…

@OrturTech, can you provide additional troubleshooting procedures for Brandon?

Here’s the latest. I processed it again from IMAG-R, loosened and frightened belts, retightened grub nuts. 6000 mm/min @ 55% and 363 DPI

What is the material? Wood?

Sure looks like banding from wood grain here.