Ran this file, but had strange results from the cut.

It’s a simple box, but I waas trying to do 10 at once.

I’ll upload the file too

Ran this file, but had strange results from the cut.

It’s a simple box, but I waas trying to do 10 at once.

I’ll upload the file too

BoxRimLid.lbrn (21.5 KB)

Is it something I’ve done in lightburn when adding the 9 extra boxes? or is it something hardware that’s caused it?

You haven’t really described what is ‘weird’ about it. What’s the problem, specifically?

Apart from this, in your file - is that what you expected - to cut through your tabs?:

The pictures show the fact that it’s not cutting right around the 100mm square and the filleted square above.

That section you screenshotted is intended

Do they? The fact I had to ask means it was not obvious with such low-res pics.

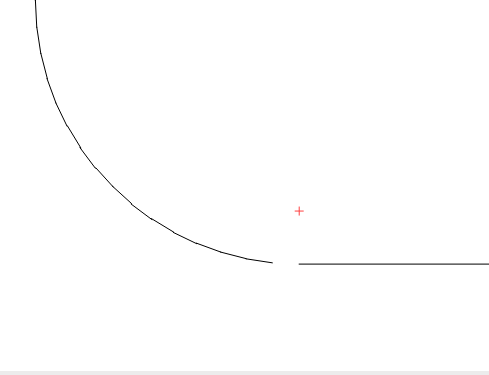

Slow motion on the motion preview shows why that might be the case:

The head is moving down from the final cut of the inner rounded square and does a hard-left turn to start cutting where it meets up with the previously-cut parts of the 100mm square.

It could be mechanical backlash not meeting up.

If you make complete shapes and co-locate their boundaries (using move-together tool), the software will handle the removal of unnecessary lines. While you have reduced your design to the minimum number of components, you’ve made editing and moving them a right ball-ache.

Have you seen boxes.py? https://www.festi.info/boxes.py/

It’s organised like that because I didn’t design it in lightburn. https://a360.co/3rxecRM It was in fusion360.

It doesn’t really matter where you designed it. The issue is as I pointed out, as is the solution.

I wasn’t criticising your approach - I can completely understand your design and why and, in itself, it’s brilliantly simple and elegant. But, in the real world, that doesn’t always translate to a good laser-cutting path using Lightburn, as well as being difficult to move and change things.

I make a lot of boxes or other finger-jointed stuff - all my ‘to market’ boxes where I take thousands of small pieces to sell are in stackable boxes.py creations. My amplifier cases start out as basic boxes.py primitives. I almost 100% do my initial base design in boxes.py - it’s not a fault-free tool, but the few strange artefacts it introduces are easily remedied.

but, to me time is money - If I can get 95% of my final design done in a tool that pops out an SVG and all I need to do is hole placement, embellishment, etc. I’ll take the automated tool every time.

for custom stuff that I need to see in 3D to check fitment, etc. (like a Raspberry Pi case, for example, or a box I am installing an amplifier, dials, switches, etc. in) I use Sketchup, just because it’s so damned quick and easy. I have been using Fusion for years, but for wood-based laser-cut stuff, I find it needs too much finessing and as a result, I use it so infrequently as to mean it’s always a learning curve, where Sketchup quick keys are in my muscle-memory.

Whatever you are most comfortable with is the right tool, but your box is pretty basic and I wouldn’t get the return on my time to design it from scratch.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.