Can you cut a large square or circle, turn it 90 degrees and see if it fits perfectly back into the cutout? I had some similar wonkiness on my laser that required more frame squareness. To my eye, even your large circle has a bit of egg to it though it could be camera magic.

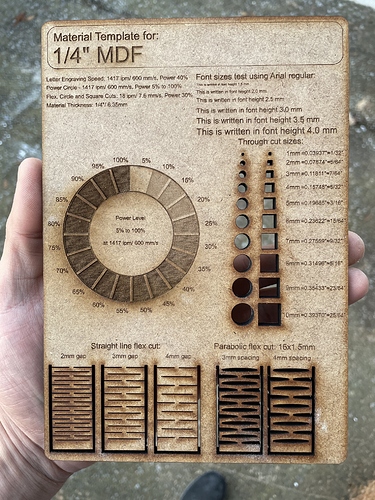

Laser Test Card - MDF v1.lbrn (1.5 MB)

Just cut out an 8" square. It fits back in but there is just a bit of rubbing when it does.

The “turn 90 degrees” part is pretty important too though.

As a different approach the op could turn the square 270 degrees. XD

haha I figured the 90 degree part was assumed. without turning it it fits flawlessly

The 90 rotation verifies you actually did correct your skew error. If it doesn’t fit rotated 90, you still have a skew problem. Doesn’t matter if it’s a square or a circle. mark one spot BEFORE you pull it apart, rotate 90, cross fingers, and hopefully drop into place.

i had the same problem

in my case it was to much slack between the bars and the rollers

i had to mechanical adjust this , so that there almost no clerance between the rollers and bars

i had to file out the roller holes

now it is pretty perfect

I ran my test card again just for the hell of it and this is the result. I think my problem was having my chiller plugged into the machine itself, instead of its own power supply, and the transformer couldn’t keep up.

What are the OD dimensions of that test card? For some reason I was picturing it bigger, not hand sized.

It’s 5.5” x 8”

Thanks, that gives me perspective.

Great! Glad you figured it out down to power/brownout issue. I have a neat little voltage/amperage meter I bought on amazon that shows volts/amps attached to the power supply for my steppers so I can monitor their output via the input. Very happy for you, nice lasing.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.