Hello folks, I have one of those 90x60 Chinese machine since 2-3 years, equipped with a Reci W4 tube (120W peak).

I never cared so much about this issue, but I started doing some works that require a clean cut and I’m now trying to solve/mitigate it.

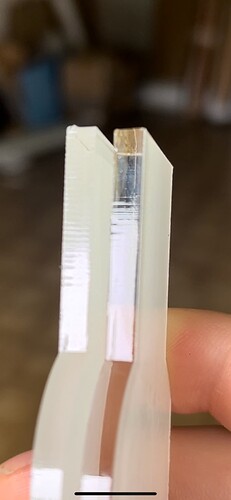

This is cut on 3mm acrylic (extruded, not cast acrylic, but it’s more or less the same on cast acrylic).

Left side is cut with standard parameters, let’s say the bare minimum so it gets cut and separates well from the sheet (25mm/s, 95% max power).

Right sample is cut at half speed, so in the extra time heat kinda melt the wobbly cut a little more and looks more straight, but I am not accepting this as a “fix”…

What should I inspect on the machine? I tried cleaning and lubricating the rails, but I didn’t experience big changes.

I am willing to take it apart, if necessary ![]()

Thank you!