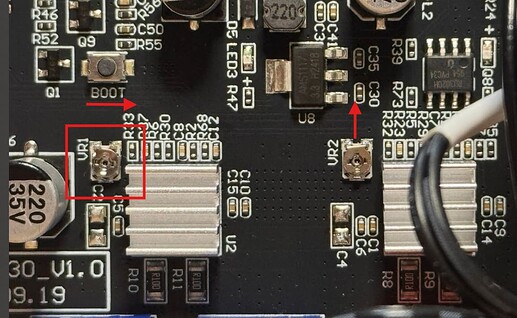

The out-of round circles are showing a little bit of backlash or looseness. The easiest way to find this is to slowy wiggle the laser module with the power off to see where the available motion comes from. You wouldn’t need to push hard enough to turn any of the stepper motors.

Pushing the laser module quickly can cause one of the stepper motors to rotate quickly. This can generate a voltage spike and destroy the stepper motor driver chip on the controller.

The progressively scattered nametag engraving looks like it’s related to Overscan.

Overscan is a feature where the laser module overshoots the end of an image while engraving.

This allows the speed across the engraving to be held constant and allows the engraver some room on each side of the artwork to slow down, stop, reverse direction and speed up to the commanded speed of the engraver.

When the speeds are high, the overscan is larger. It takes more room to slow down. The art must be moved further away from the edge of the work area to make more room. The progressive scattering happens in one direction (at the end of the nametag). It’s showing that you’re engraving an image or ‘filling closed shapes’. This is all set correctly and looks good!

I believe that the laser module is hitting the frame or chassis on the side closest to the beginning of the nametag. The progressive scattering away from the beginning will stop when the nametag is far enough away from the frame or chassis to allow the engraver to apply the overscan.

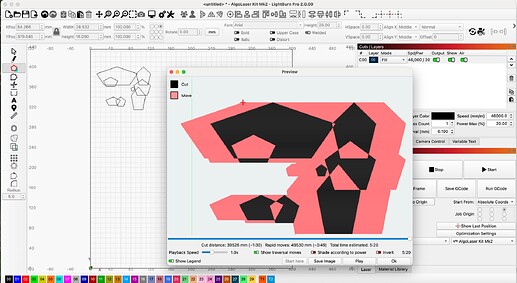

The expected overscan behavior can be inspected in the Preview window. With your project loaded in LightBurn, click Window in the top row, and then Preview. It’s near the top.

In this window you’ll see the project as the laser would receive and understand it. You can zoom in and out with the mouse-wheel. If you’re seeing red travel lines, you can see if the overscan is crossing the workspace. If the red lines aren’t there, you can enable this visualization tool by enabling the switch marked, “Show Traversal moves”

Here, the quick sketch is showing the overscan (on filled overlapping closed shapes) extending beyond the workspace (the green line).

The art needs to be moved to the right in the workspace in LightBurn, so the overscan can’t drive the engraver into the frame of the engraver.

In this example I set the speed excessively high to exaggerate the overscan behavior.

When you need to make a large project that is close to the limits of the engraver, you can cut both speed and power to reduce the overscan to maximize the size of the art that you can produce with your machine.