I am running a Comgrow Z1 5w fixed focus diode laser.

all the vectors were ran at 750mm/min with 40% power

I am approaching my wits end with this machine, I have been marginally successful with raster engraving, although it’s always been somewhat “off” when compared to the results of the old Ortur I used to run. as in the dithering was not exactly how it should be. As I have begun testing and retesting I have noticed that it likely is part of a larger issue that becomes much more visible when trying to do vector engraving.

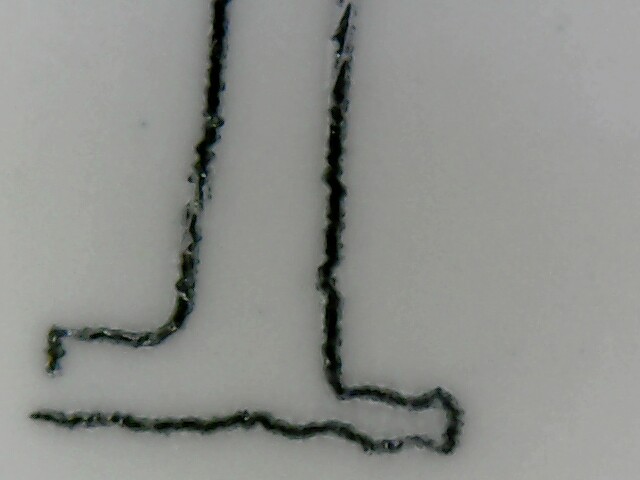

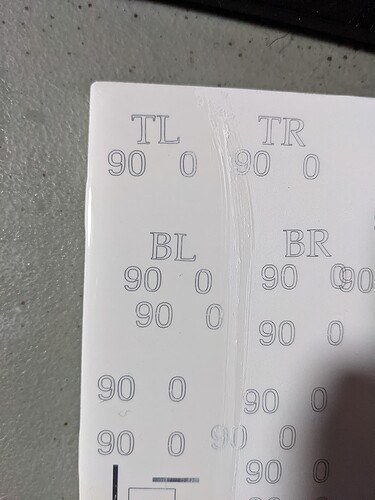

The issue seems to be there is slop in the actual position of the machine vs where the computer thinks the machine is. this is far more noticeable when raster scanning at 0 degrees as opposed to 90 degrees. it also comes to light when trying to run vector shapes with curves or lots of directional changes.

In particular, I had been running scanning tests with 90 and 0 drawn in as vectors and I noticed that with all of the vector shapes that were line drawn, none of the circular shapes had been properly closed, and there were wobbles and squiggles throughout the lines.

I initially assumed that this was due to belt tension issues, however after ~20 different rounds of trying to tighten the belts I am relatively sure it is not a belt tension issue. I moved onto the eccentric nuts - I have tried tightening them and loosening them to no avail, although I am much less familiar with making adjustments to them so I am less confident it is not related to the eccentric nuts.

I noticed that the wheels had strange wear patterns in a few of the wheels, so I replaced all of the wheels - no change. I swapped out the belts that I got with the machine to belts I had been using with my old machine and did not experience this issue with - no change.

I am willing to try just about anything at this point I am just out of ideas on how to move forward troubleshooting this issue. I have found a user on the Ortur facebook group who had a very similar issue, their resolution was to junk the machine and get a different one - not the ideal solution.

On the Den of Lasers facebook group the only similar issue, I could seem to find indicated that the lens may be loose. I have not looked too much into this, but with a fixed focus machine, I am not convinced that this is my issue.

again any help or ideas on how to move forward trouble shooting is appreciated.

Here are some photos of the results I have been getting with the current battery of tests: