Afternoon guys and gals, I have now got air assist set up and seems to be running ok, but there seems to be signal problem from the computer…

Ok…all was going great, set up another small job of 3 spacers with some engraving the engraving got done the Air came on and I got 2mm of the cut and laser just froze with the laser still on…

The only way I could stop the laser from continually firing was to turn off and pull both cables (power and Data)…

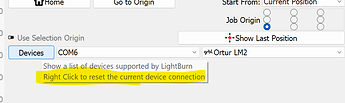

Still could not get it to work so I changed the Com port and it made a clicking sound and then I switched back to the right Com port and sometimes that helps and others not so much…

So my thought was the Data cable ( I think that’s what it’s called) but that was replaced by me about a year ago for a better one, So I again thought maybe I should try a powered USB Hub…

Sorry I have no technical info or pictures I was so frustrated I just shut down I come inside to calm down before heart attack..

The cable I’m currently using has this info on it if it helps…

USB Shielded High Speed Cable

2.0 Revision

28AWG/1P+AWG/2C

ROHS Compliant

and has gold plated ends

Cheers Merlin…