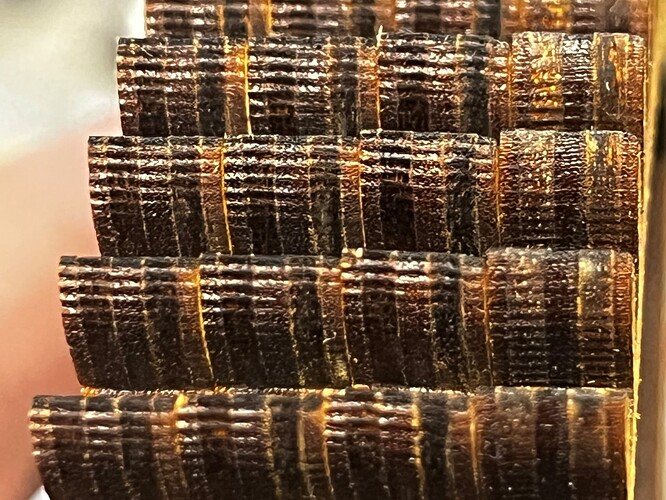

I’m cutting wooden gears and having issue with jagged edges. I’ve been trying different settings, without much success, and found a couple settings in the advanced mode that I have never used before, dont know what they do.“dot mode” and "override PWM frequency " any body know what they are about or know what else might hel smoth my cuts out Im cutting on a BOSSLASER LS 5536.

Those lines remind me of this image from our job troubleshooting page!

That looks very much like a mechanical issue. Perhaps a belt is set a little too tight or the microstepping is set too low. Please post your machine settings and cut settings to be sure they all look ok before you start poking at your machine.

How big is are the teeth?

Is there anywhere your belts or drive train have this spread?

It looks like curtains…

It’s too consistent across the whole area, so it appears mechanical. If you have a gear ratio between the stepper and the drive to the axes, this is also a possibility.

Never used dot mode …

The Ruida can change the period of the pwm signal… it’s 50uS (20kHz), I believe. I’ve run mine at 1kHz.

With a dc excited co2, the pwm is dealt with through filters that produce a dc current control voltage. Many Ruida controllers also have a analog output of 0 to 5V that can be used. I’ve changed mine, for academic purposes. This might be of benefit to an rf or other type machine, but doesn’t really do much for a dc machine.

What is the material made up with? It’s interesting how the different layers cut…

Good luck

![]()

Dot Mode does exactly what you don’t want: pulses the laser along the cut.

Unless you have an RF excited laser tube, that should remain at the default of 20 kHz.

Does the machine produce similar irregularities on other materials? Do the results differ on straight sides vs. curves?

Test cuts in paper / cardboard / MDF would be revealing.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.