Hi. guys

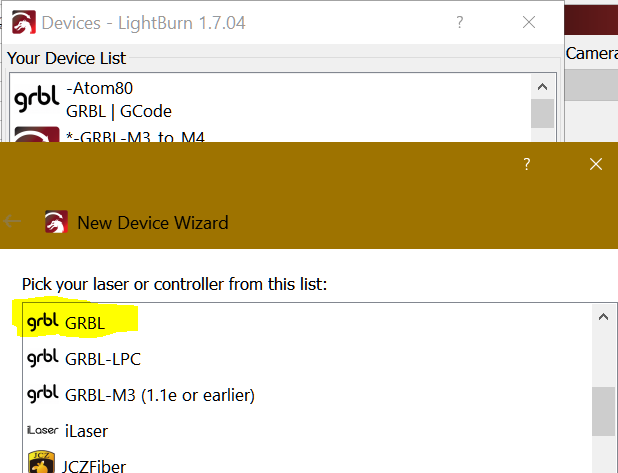

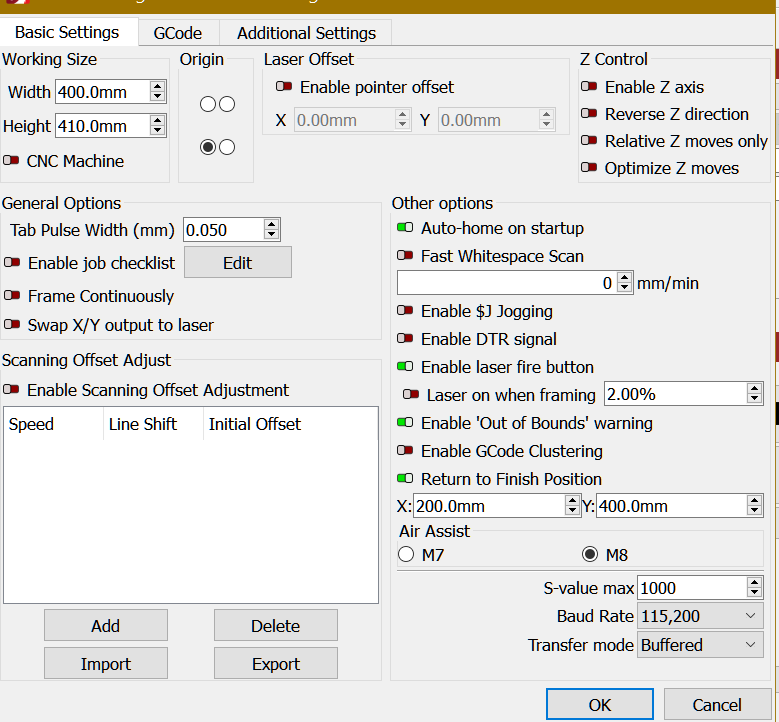

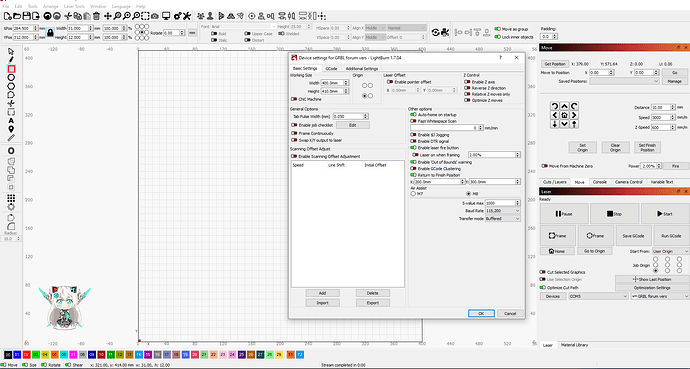

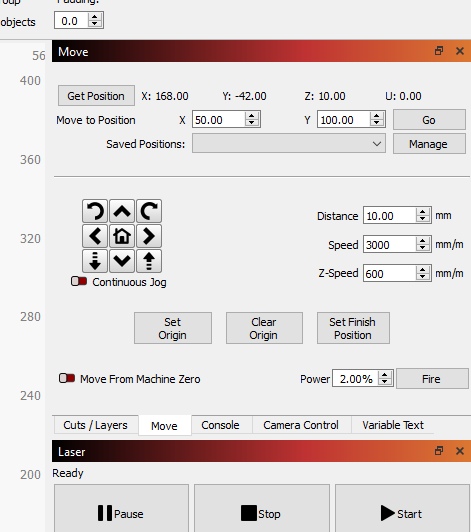

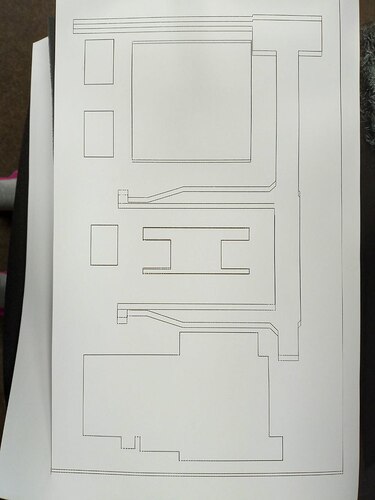

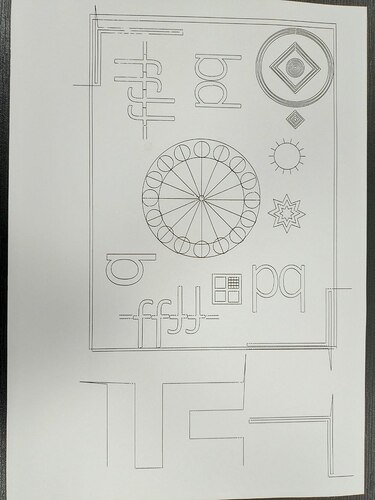

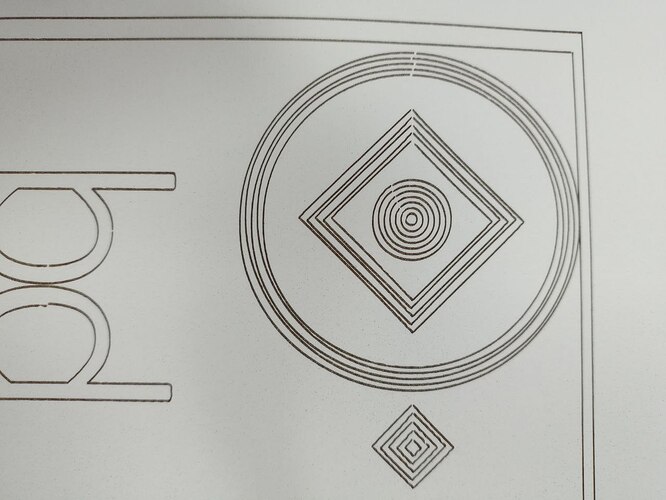

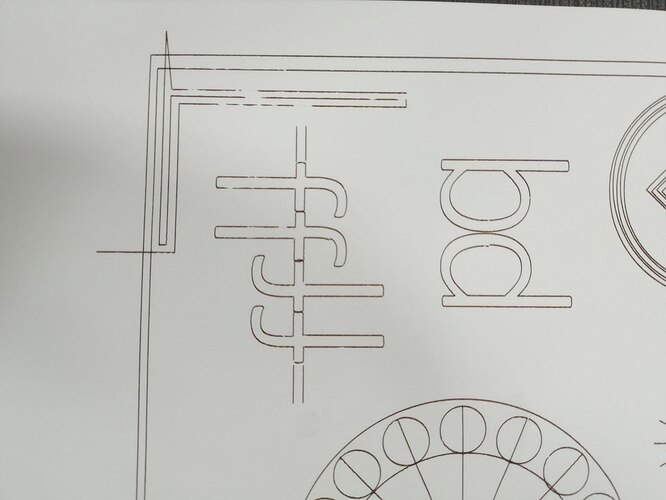

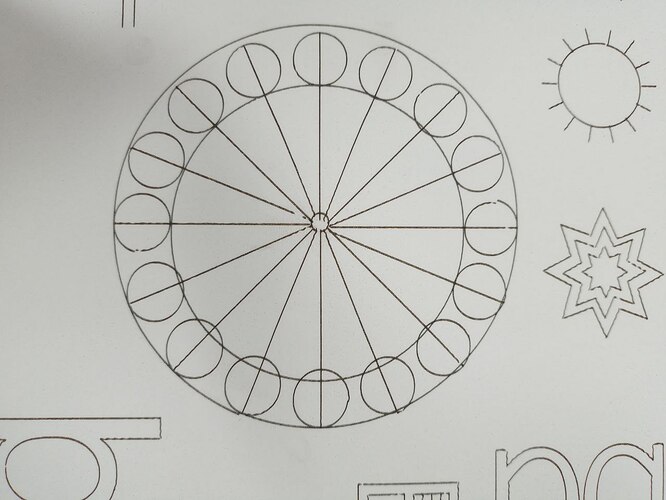

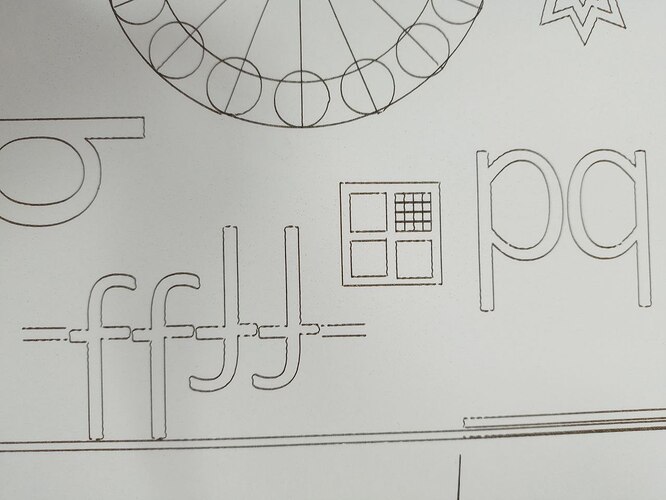

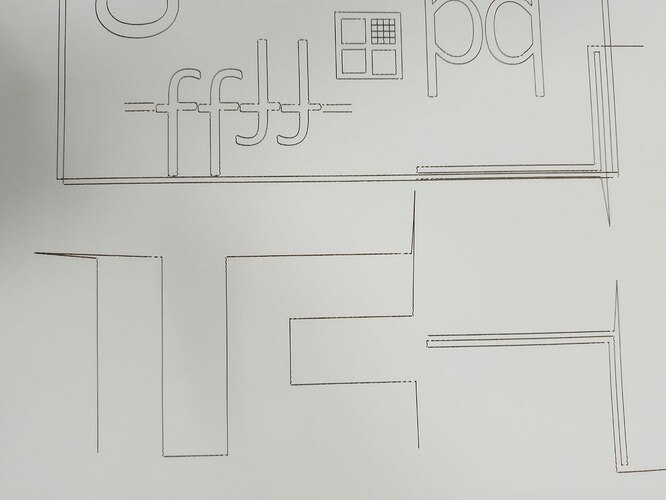

I have a problem with Neja3 and RGBL-LCP. I try to change ccordinats, because i have negative coordinates on Y. I did G92 x1 y1 for 0 position, did $10=0 and when i try to move on 10 mm all is good, but when i try to do a figure, it`s looks like my laser forget all comands that i did in console before