I’m new to the whole laser world, I bought the Xtool D1 Pro 20w kit with the RA2 and new IR laser module. I bought 6x6 squares of brass, copper, aluminum and stainless steel to do some materials tests so I can have an easy reference for future projects. I know Lightburn can make a materials test grid but I’m still not overly familiar with the program and I can’t figure out how to make the grid fit the size area I want so I set out to find some settings for the IR laser and found that it’s nearly impossible to find any information on the web (unless I’m just not searching using the right key words), so I just started trying different speeds. I ran test after test without leaving a mark on the metal.

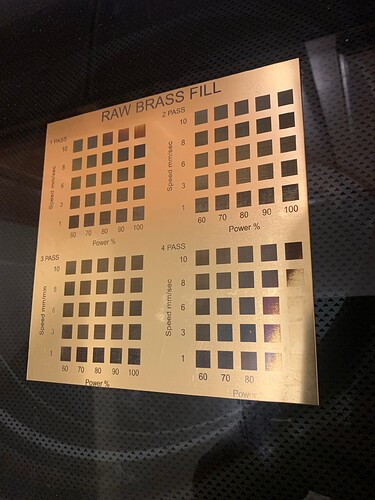

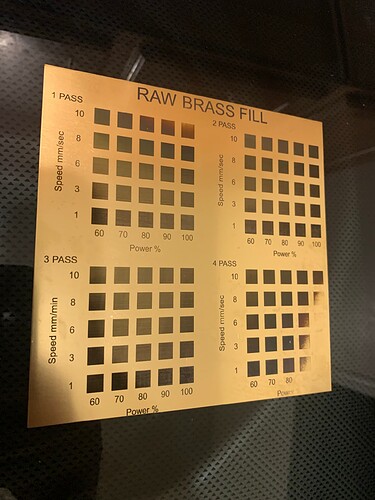

Ultimately I ended up running a ramp test last night and found that the focusing arm placed the laser about 1/16 of an inch too high. After manually setting the module height I set out on my path to making my test piece. I wanted to create a test piece with four 5x5 grids ranging from one to four passes (to see if I can get the different colors the laser is supposed to be able to produce). The settings I found that give the best results are speeds between 1-10 mm/sec and power 60-100%. Of course that’s super slow so now it’s a patience game as it’s going to around take 25 HOURS to burn all four grids! I don’t think I can increase the speed much more than 10 mm/sec as the higher end of the power settings at 10 mm/sec is fading out.

I’ll post a picture of the finished test piece when it’s finally done so hopefully it can help someone else looking for IR laser settings down the road.