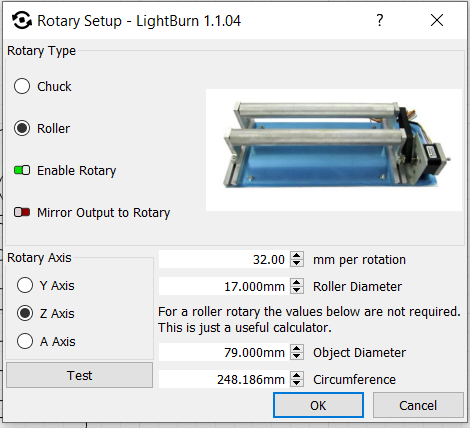

I did some testing today and believe I figured the issue that people had with their rotery device after updating their firmware. Pre update in the rotery setup menu you inputed 360 mm per rotation (actually degrees). After the update the rollers are 32mm per rotation. I believe this was done to better support the ra2 pro and make it easier when switching between the chuck and the rollers. The chuck is 128mm after the update

I made this change to 32mm per rotation and it doesn’t change my rotary movement at all. It’s as though the change to 32mm has no affect on operation.

What exactly is your rotery tool doing? Have you recently updated your firmware. Take some screenshots of the device settings and rotery settings.

My Rotary is moving much farther than it should be moving. If I jog it a certain distance, it moves much farther. I set a cup on my rotary with a circumference of 262mm, when I jog it 262mm, it rotates 1 3/4 rotations. I did recently update my firmware, and I made the changes you suggested to 32mm per rotation vs. 360mm. The 1 3/4 rotation was happening with 360, 32, 100, 120, or whatever I put in that setting.

In the device settings enable the z axis. Its in the top right corner. See if that fixes the issue.

Yeah, I did that. It didn’t make a difference.

Interesting. That may be out of my knowledge level. Another method you can try is make a line on a work piece. Input a number into the rotations per mm. Then click test. Keep tweaking that number till it only rotates once. Or is that what youre doing when you say jog it?

I have tried so many different numbers for that setting. The movement doesn’t change. It’s like my machine isn’t taking the change. In GRBL, $102 is set at 0, that’s supposed to be the setting for the Z axis, 100 and 101, for the X and Y are set to 100. I even tried changing it there, but it will not take the change.

Are you using user origin for the laser position? Something else i noticed that would happen too is the green dot that indicates the starting origin would be at a different location then indicated by the 9 dots. I am still pretty new so that may just be an error on my end somehow.

Yes, I’m using “Current Position” and the top left dot.

Hey, I appreciate your help, by the way. Thank you.

Yeah no problem I just wish i had more experience to help you solve the issue. My next test would be getting a scrap work piece. Putting that on the rollers. Get your measurements inputed and set 32mm for the rotations. Then draw an inch line and burn that. Measure that line. This is where i noticed the green origin dot being in a wierd location. I had to grab and drag the line a bit to get it to line up. I have zero clue whybthat happend though. Anyways, if that line is exactly 1in on the work piece then it may just be something funky going on with the jog.

I did a test. I made a 2.5mmX100mm rectangle and it engraved a 10mmX 10m square, on a cup.

I’m at a loss. I wish i could be of more help. Is this only occuring with the rotery? What about with laserbox?

LaserBox seems to work fine. I have a work-around by unlocking the image or whatever, then reducing the height by a factor of 4, then relocking it. It seems to work OK like this. I do appreciate the help.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.