There’s no “idiots guide”.

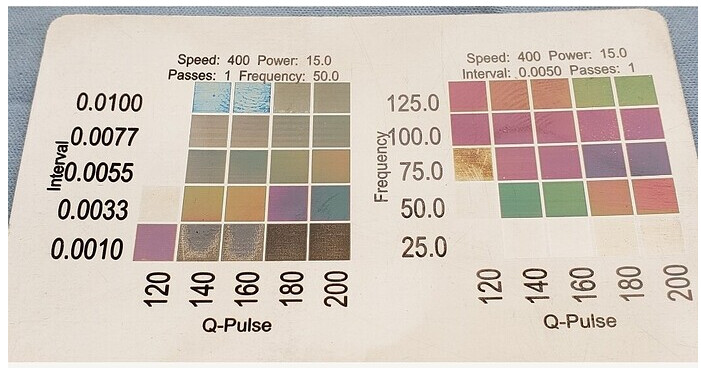

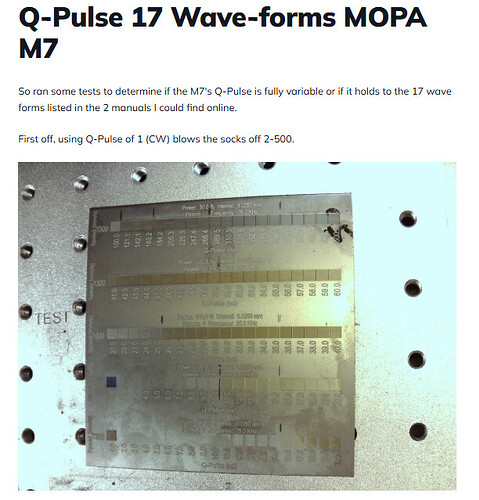

I’ve looked around a lot- there’s very little reliable info on how to operate them. I have an M7 300W and finding the best way to high quality engravings at high speeds is still confusing as hell.

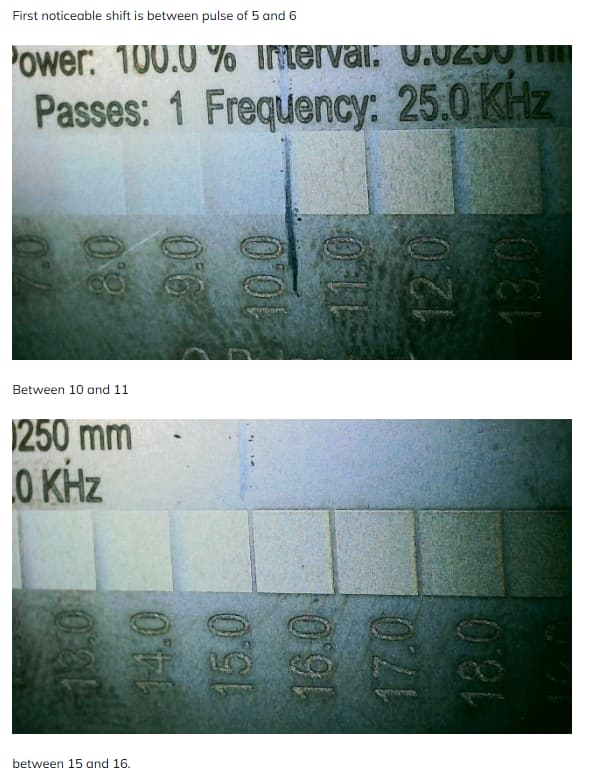

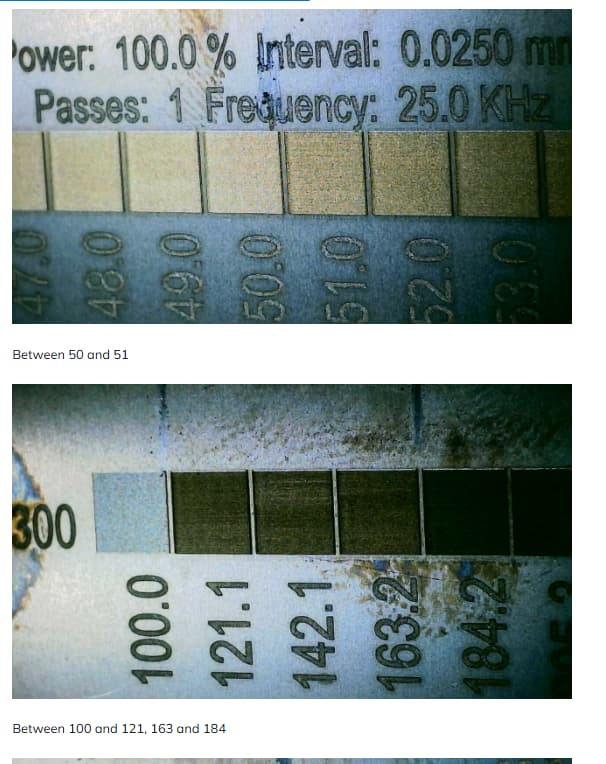

If you hit it too hard, a coin will heat up and warp. Also I look under a microscope and can see where it appears the metal spatters out of the cut only to solidify on the top edge of the line, making the engraving very rough.

I am confounded because, like, I get a hint of decent engraving at one point and want to compare with running slower. So I keep the q-pulse the same, keep 100% power and 0.02 LI, but slow speed from 5000mm/s to 1000mm/s and reduce the pulse freq to 1/5th. So it should be the same in terms of pulse energy and pulses per mm, it’s just being delivered slower.

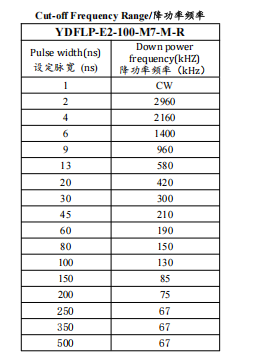

But the engraving was MUCH shallower. I don’t see any reason why the pulses would be weaker when pulsed slower, both runs were below the cut-off freq so the profile of each pulse should be the same.

Now, if I were varying Power instead, I could easily write this off as nonlinearity , but that shouldn’t apply to Freq like I did.

This might be due to the reduced metal temp overall when getting pulsed slower.

Basically it feels like this is all about the ratio of material removal vs how much heat the pulse delivers to the metal substrate

Working on a coin is different than working on a thick bar of metal. The coin overheats much more easily, it will warp and warped material cannot stay in focus.

I could see the coin faintly glowing a dull red if I hit it too hard. But also, I could melt the surface of the metal without overheating the metal overall. This could produce a smooth surface but overall the graphics weren’t coming out well.

I’m still doing a lot of experimenting, I currently think the 60ns-80ns range may be the most effective for engraving. And I’m controlling the depth primarily by reducing the freq rather then Power.

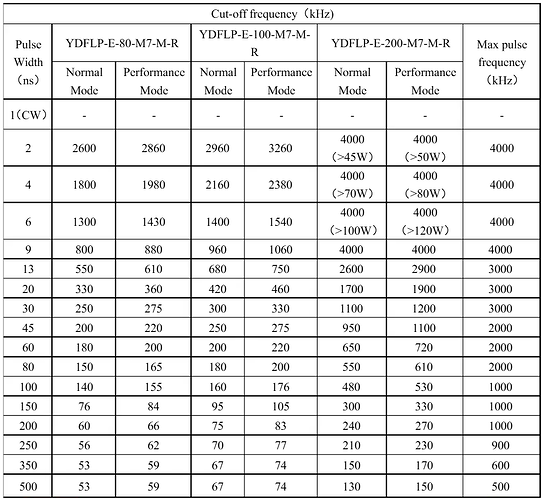

I was working with the 2,4, 6, 9ns range that I could pulse up to 4000KHz by the manual. Overheating the coin was pretty often the result.

I do have examples were the taller features engraved one way, but the deeper looked radically different. This could be due to the focal point needing to be lowered, but the engraving probably wasn’t deep enough for that to matter. I think it was doing something totally different because the metal was at a higher temp on the later passes.

And it went both ways- some examples, the highest points seem to be melting into a shiny surface and actually had some good detail there, but the lower depths were a mess. Versus others where the higher points were muddy and it became shiny on lower parts.