I’ve upgraded to stepper motor control of z axis to allow bed height control from Lightburn. I am now able to rise and lower the bed from the controller (RDC6445G-EC), however I can’t calibrate steps to match actual travel. I got the bed to move through trial and error at step length of 1.77. Then I measured actual travel vs displayed travel and used the “calculate steps” function on the controller to get actual step length (.067240). Problem is, the bed won’t budge (motor stalls/ squeals) at this setting. I have tried adjusting controller displayed speeds from their default (380/10/10) down to 5 with no result. I also tried adjusting the driver voltage upwards with the dip switches, and changing the Pulse/Rev dip switches. Not sure what to try next.

Settings:

Step length 1.77

max speed 380

jump off speed 10

start speed of key 10

Changing the step to even 1.8 or 1.7 yields stalled motor, as do adjustments to speed

Parts:

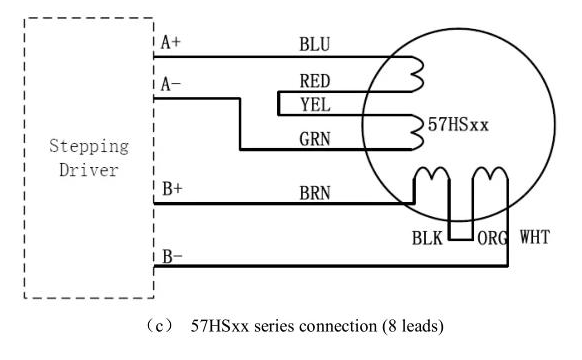

DM556 Microstep Driver (dips set to 4.3A Peak and 400 Pulse/Rev)

Leadshine 2 Phase Stepper Motor 57HS22

Ruida Controller RDC6445G-EC

I used this excellent tutorial from MW Laser, however step length is different for each machine so it is of no further help. Z Axis Upgrade on Red & Black Co2 Laser with Ruida Controller - YouTube