Well, life happens and you never know when it’s going to barrel at you full steam. So, I’m circling back to this question again because I wasn’t able to respond to my other post before it was closed due to “Life” happening. ![]()

I want to thank Jack Wilborn for his reply and link to that post - it did help, some. But it’s still a very confusing thing, trying to understand which Z-axis setting is for what exactly. But I was getting better at it. And then…

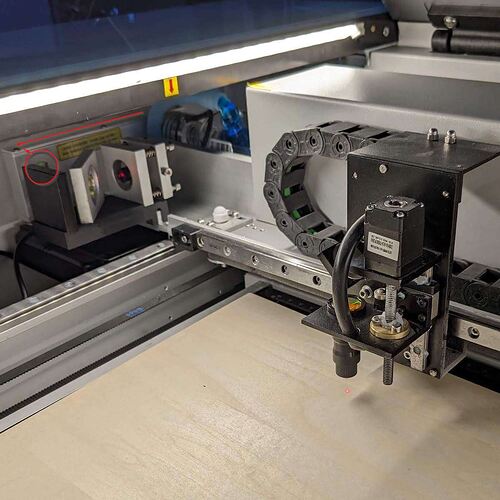

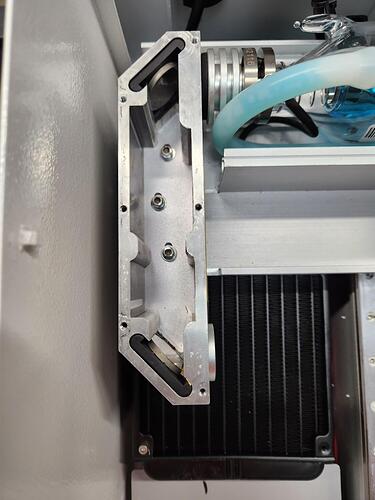

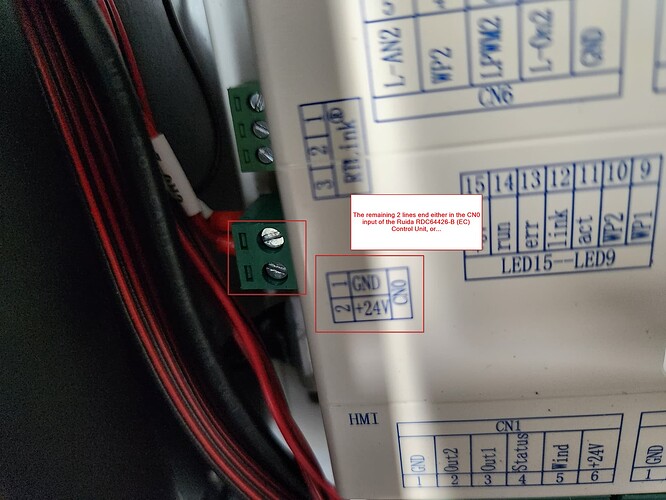

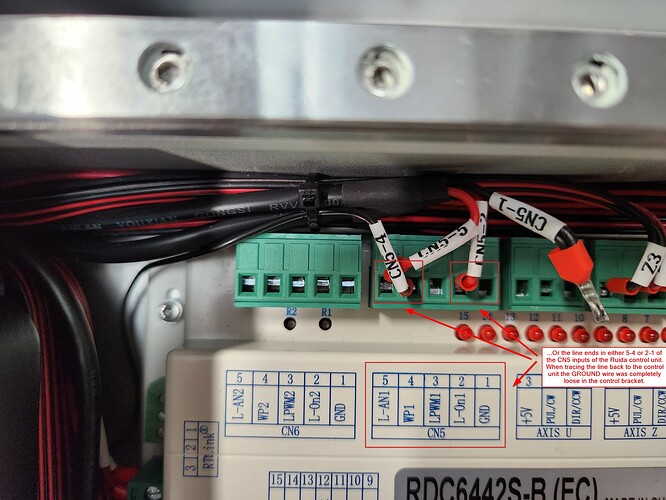

I found a YouTube video from Edmonds Workshop about adding the Cloudray Ruida 6442S Control Panel to my Polar. Game changer! I did the ramp test - multiple times - and now I simply use the Z-axis control on the 6442S to lower it to the setting I want and away I go! HOWEVER…

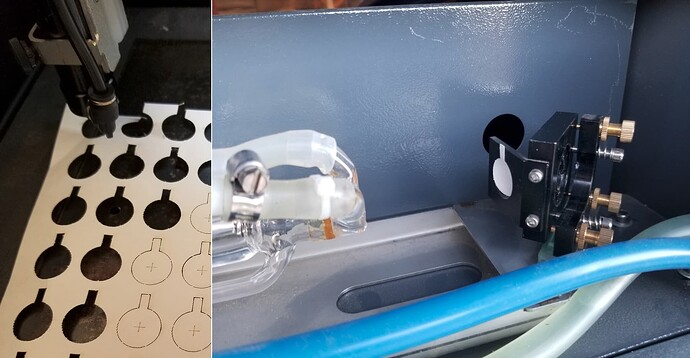

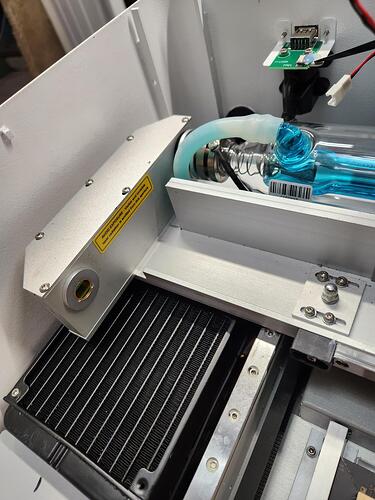

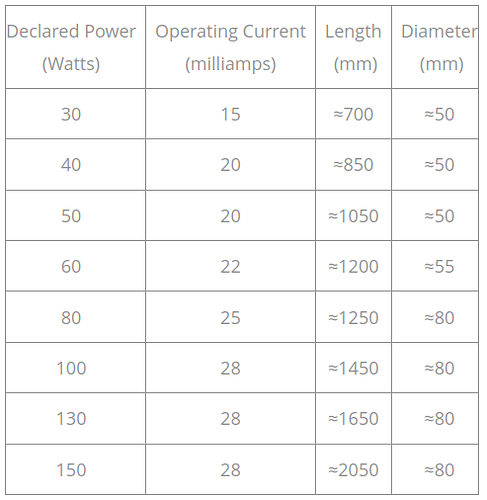

Ever since I received my Polar it struggles to cut anything. Whether I use the OMTech formula to set the height according to the formula within Lightburn or manually focus with the controller, I have to set the power and speed well outside that of everything I can find out on the webs. I ran my ramp test multiple times because of this cutting issue, but every test the point in the line that is perfect is right around 13-14mm, and if I use that height it takes far too many passes to cut through.

I have a 10-watt diode laser also. On some woods it struggles, but I can get a clean cut within 6 passes on the hardest 1/8" ply. I work with a lot of Birch ply, but I have a Basswood ply that my diode cuts in a single pass, like butter it’s so soft. But my Polar struggles with that same lumber.

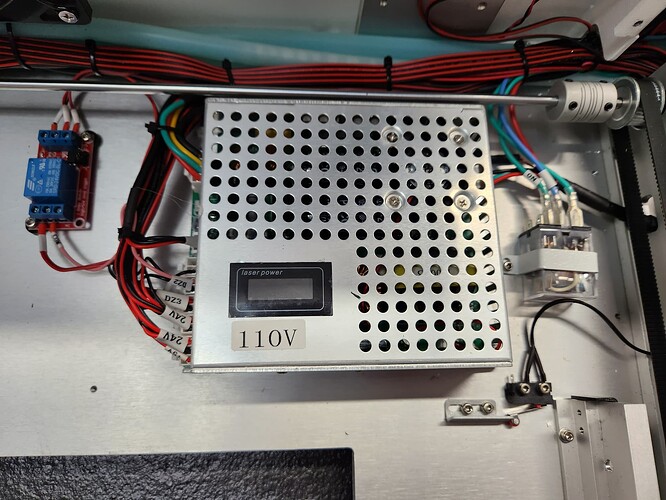

The Polar engraves really well at the correct setting according to everyone else - 150mm/s @ 21% +/- power depending on the wood. But the average cut at 10mm/s @ 26% +/- power and it’ll surpass 5 passes on 1/8" Birch or Basswood before it starts to cut through in spots.

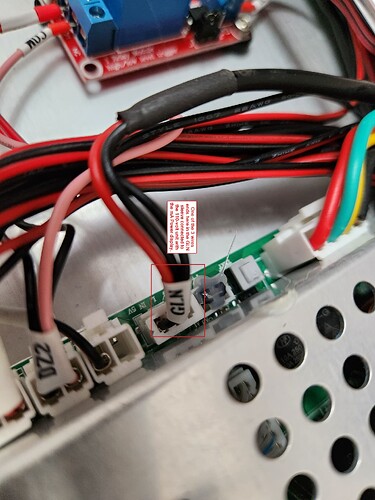

Yes, I have turned the potentiometer on the back all the way to the right, even backed off a smidge just to see if the full turn caused an issue, but no change. And turning left on the knob lowers the power, as expected. I have cleaned the mirrors and lens with a glasses cleaning cloth and 99% alcohol. I took things apart to check for damage. I’ve watched the Ammeter and it’s spot on for power settings, not low or high.

Right now I have to set my cuts to 10mm/s @ 40% power (5-6 mA) at a height of 10.6mm to get through my 1/8" Birch and Basswood in around 3 passes, but they aren’t clean cuts with a lot of fibrous connections and plenty of burn.

So, is there anything else I should look at? Could it be the lens supplied by OMTech? I am planning on upgrading the lens to the Photonics OMTech Polar Magnetic Lens and Tube kit simply because my large, oafish fingers have a helluva time pulling the lens out for cleaning, but I imagine there are differences with lenses?

Again, any insight and wisdom is greatly appreciated. The more I learn, the better I get and the more I’m able to help others with their lasers in my local community. And a lot of that knowledge comes from you, here. So, thank you, all! I’m really good with diodes now, but this Polar and C02 laser has been a bit of an adjustment. And I really would like to resolve this cutting issue because I see others use their Polars and they have no struggles at all. So again, thanks for your help!