I am a newbie…My laser just arrived a few weeks ago and finally got everything hooked up. I’ve looked at the power recommendations for a 100w laser but they seem too high and is scorching my 1/4" baltic birch. I wondered if anyone had any insight on power recommendations for this laser.

Hi Lori,

It will all fall into place after you get time to do a number, normally a large number  , of test pieces with varying power settings and speeds.

, of test pieces with varying power settings and speeds.

A 100w has a lot of potential and needs a degree of management.

You should be able to do your cuts with very little scorching either on the top, bottom or walls of the cut, it really is just a matter of testing.

There are literally hundreds of videos available on YouTube dealing with cutting and test proceedures that will get you ever closer to your goal.

I’m working with a similar machine and a compressor for air assist ( this makes a huge difference, huge) .

A ball park set of numbers would be:

Power 30 percent

Speed 20 mm/s

Air assist full

2 1/2 inch focal length lens

Maybe it’s obvious but will say there are various approaches, however, leaving your power setting the same and varying your speed will get you to your goal as will other methods but my advice, while you are gaining experience is to decide on one method and stick to it.

This really is a subject where’s there’s something to learn every day. Mechanical, optical, materials, patience, lots of patience, but great rewards.

Please give it a try and send images of your tests. It’s good to write power and speed on all your test pieces.

You will see ramp test referred to, check it out and do at least one

Talk soon

Gary

Hi Gary, Thanks for your response. I really appreciate your suggestions and will start narrowing my research to your recommendation.

A side question if you don’t mind, since you have a powerful laser… Do you use an amp meter? If so, what is the range you try to keep it within to preserve the life of the laser?

Hi,

In relation to the mA meter. I have fitted one 0/50 mA but to be honest I don’t use it.

I always test and to date have never used more than 30 % power on anything.

I’m using a 130w so 30 is enough.

I just keep mirrors and lens clean and use air assist in cutting, almost none engraving.

Your stuff looks cool for starting out, …

If I’m reading your power speed accurately then the higher power ones are definitely showing the burn and air assist would help greatly there…

Your 52/40 is getting there for sure  good job you.

good job you.

I’ve also found much written about materials choice and especially with plywood…there are many choices in the US, more than here in Bulgaria

Even so much of the ply can be poor quality and contain quite large pockets of glue which is a devil to burn through and can ruin a perfectly good job.

Something else used by people to hide the smoke and burn is what is called transfer tape. It’s used by graphics companies in placing vinyl material on windows and vehicles. Others use painters masking tape. The idea is you burn through it while it’s stuck to your job then you peel it off later uncovering the clean wood underneath. I tried it but since switching to a compressor air assist, there’s no need.

I know I go on about air assist, but, what to do

That’s the next installment

I’m going to go the other direction. I have an 80W laser. When cutting plywood or solid woods of any thickness, I get my best results with higher power and faster speeds. I will typically use 70-80% power and go as fast as I can and still reliably cut all the way through in one pass.

For 1/4" I’ll use my 75mm lens, though my 50mm also does a good job. I set the focal point to be below the surface of what I’m cutting. I also use air assist near full for cutting. Not so much for engraving or 3D relief.

I recommend you run a few passes of the focus test in lightburn ( if you have a controllable Z axis ) to get an idea of the focal range of your lens. You can also do something similar manually.

One of my machines has a Reci W4 - do you want my materials library?

What a cool thing to offer

Say yes say yes :))))

I would love that as well… I have a RECI 100W, and do multiple passes when cutting 1/4" ply… though I don’t need too. Viewing your library would help us all here… maybe you could upload that into the files section?

very generous

I agree with Joel, this is also my tactic. Highest possible speed with least necessary power. It gives me the best results - in wood (veneer, mdf, hdf, etc.) but it does not apply to acrylic, here there are the material’s completely different properties that require a different technique.

You can use the common test procedures that are found everywhere on the web or make your own test piece that repeats in a series of different values until you are satisfied - remember to document it for reproducibility. (I do not want to make them as big as yours)

Regarding ammeter, I will by no means do without this important instrument. It is possible that I mostly use LightBurns% power settings but I regularly check if the% settings follow mA. CO2 laser power output is not linear, so in fact you do not know where you stand at the different software percentages. (unless you have reduced your power supply to fit with LightBurn`s percentages - that’s the smartest thing)

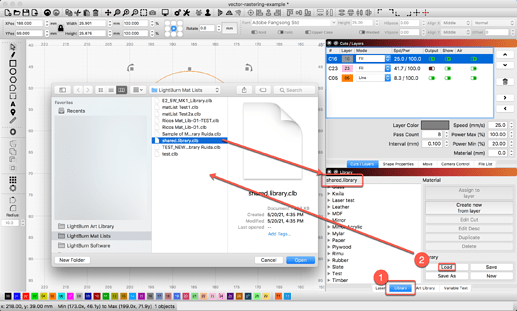

Rename to .clb, from .clb.txt

shared.library.clb.txt (227.6 KB)

Hi Lori, the guys have offered great information, for me the more important is , for now, while you are gaining experience, use any one of the methods.

Get some knowledge of your machine and materials then broaden your choices based on what you then know and feel comfortable with

Thank you for sharing! Extremely well organized and professional. THANK YOU

Yes, plz! That would be wonderful!

Bonjour, Thank you so much for your help. I looked at the file, is there a way to import the setting into Lightburn? Or do I just manually enter them?

Hi Bo, I hope you don’t mind me answering, its your great file and I imported it and combined it with mine… Thank you

Guys about using this file…

Put it in a location convenient to you, I put mine in my

SDCard ****** lightburn_other_docs ***** folder and then

Enter LightBurn

From Window (Top Menu) select Library and the tab will open on the right as part of the other windows you have like ‘Cut’

In the Library wondow look extreme right at the bottom and there you will see ‘Load’

Navigate to where you put Bo’s file and enter it… It will open in the library and will load every time you open LightBurn

Thanks again Bo

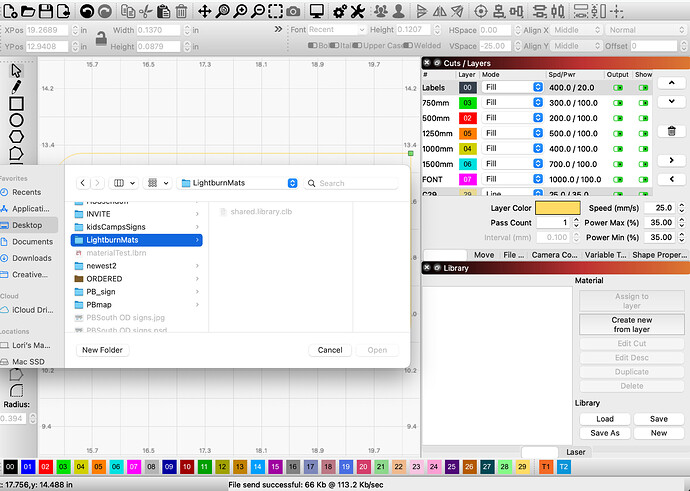

TY so much for you help. Although, my lightburn will not allow me to load that file. It’s grayed out like its not a valid file. I changed the name to be: library.clb – is this the correct extension?

What window are you trying to load this file from? Here is what I did to get this shared ‘Materials Library’ to load in my LightBurn.

From the ‘Materials Library’ window, hit the ‘Load’ button to pop open a file manager window, allowing you to navigate to and point at the library file you’d like to load. Then click ‘Open’ to open and load that file into LightBurn. The Library window will update, showing this newly loaded materials library information.