Hello, i would like to know if someone with 130w tube have good engraving results with high resolution. Like photo engraving, granite engraving, glass engraving etc. Wondering because of high wattage and probably big diameter beam won’t have that good result. Any photo results is much appreciated.

What is “good engraving” is very subjective. Cloudray makes an engraving lens that works well but I don’t think you will ever get to the quality of an Epilog.

I don’t mean Epilog or Trotec quality. Just good quality that can an 60-80w do because of smaller beam diameter and lower wattage

I use the Cloudray engraving lens on a 90W tube. Keep in mind that you can’t cut with that lens at high power. So it’s kind of a bother switching lenses.

Larger wattage machines can’t lower their power levels as low at a small tubes. In the end these CO2 machines aren’t ideal for engraving

Not to mention the material and whether you use a mask or not. It’s just something you have to play around with.

Here is an older post on the topic. “Good quality” on engraving has to do with the ability to control the beam. Either with power or diameter or both.

The problem with larger laser tubes is the minimum amount of power that it can output.

Here is a thread where @LightBurn explains why

Do you have an example of very low power needed for a material that 130w wouldn’t be able to engrave because of the extra power?

For example with 130w will be possible to make rubber stamps? That needs small letter engraving and probably not too much Watts

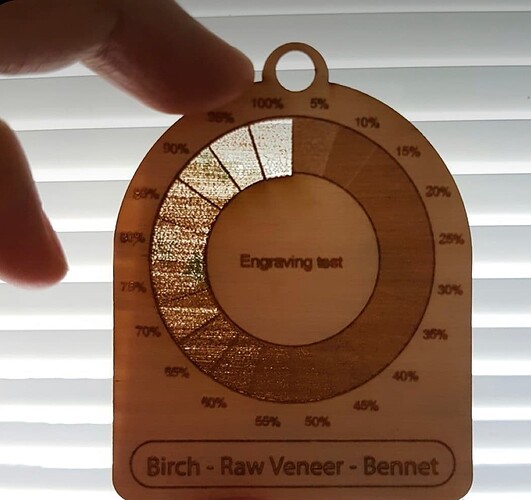

I think you would learn more if you posted the pattern, type of wood and let folks post an image of the engraving.

Here is an engraving that I picked up in a woodworking show a long time ago. It’s 60mm high. If someone had the image it would be interesting to see how well the pattern could be cut.

Don’t know about detail, but try this one…

This is it, reversed and done on the back of a 12" square mirror, then black paint.

IMHO, a laser is either lasing or not. There is no 50% power, just 100% power for 50% of the time… When it does lase, it will draw whatever current the lps can supply.

That means you can’t get less than full power when it does lase… That makes it easier to engrave delicate items with a low power laser…

You want me to believe that a big truck will perform the same as a small sports car on a tight slalom track … bigger is rarely better

There is also a response time between when you tell the lps to lase and when the tube actually goes into resonance and lases.

If the laser has the minimum response of 90% voltage <= 0.1mS that would limit how fast you could possibly go and maintain control… speed is the only real control you have and that’s limited by the response time of the tube… ![]()

![]()

So you want me to believe that a small sports car can deliver your BIG screen TV the same as a big truck can?

You are correct in saying that a smaller wattage laser will output a smaller energy beam however dismissing the power feature within Lightburn as not useful because the laser will not take advantage of the adjustment is just wrong.

![]()

What type of laser is used for this?

You can use either Diode or CO2 lasers.

Here are a couple of videos

Engraving on the back of the mirror allows light to pass through or you can paint it a different color.

![]()

It doesn’t really matter what the software can do if that translates to something hardware can’t manage. IBM used the term ‘unpredictable results’ when you attempted things that were essentially undefined operations.

You can set a layer to much faster than the machine can run. You can set your dpi to something unattainable. How is this software related?

There was no direct point at Lightburn being bad at anything … it was about the how the machine works …

If you take that you can control power… then a 130W tube at 10% (probably below where it will lase) then you get 13W… a 50W tube at 10% is only 5W. If 5W will do the job 2.5 times that power that is going to toast it…

One of my first cars was a Triumph TR3… There is no way you could put a big tv in it, or on it … Bigger is for bigger jobs, much like a screwdriver, hammer, tires… ![]()

Rather moot anyway as he’s got a 130W I think…

It would be interesting to see if the dot it makes from a larger diameter beam is really smaller to any real useful degree…

I know I’ll never have anything that big, no real use for that much power… of course if I had one, I’d probably find a use for it…

![]()

Still not ordered the 130w and thinking to go for 100w Reci or something else. Maybe is the golden section of engraving and cutting. I also have a CNC router for bigger jobs. So maybe 100w is better idea.

What materials need for example 5w and i will have issues?

Light woods, such as basswood, cork and balsa. I cut targets out of coloring paper for the alignment process a sheet at a time. The LBT100 needs a real light touch and I run it at 500mm/s @ 13% or there about…

The advantage to big power is cutting ability not engraving. If you are going to do lots of cutting of thick material you get a big laser. Big screw, big screwdriver…

Good luck

![]()

There are two limitations here.

One, the HVDC-excited tube’s power supply has a 1ms response time. So it can turn on and off pixels at most about 300Hz before it’s just a blur.

Second, these tubes cannot go below about 20% minimum output power without going unstable and then there’s no output. It’s not possible to get output from the tube below that. This is more of a problem with larger tubes that have a higher minimum output.

Also, a 2" FL lens has about a 0.2mm focal spot size, line interval gets set to that. Rough estimate, depends on material and power level. A 1" FL will have a 0.1mm focal spot- this comes down to diffraction limits, it’s an equation.

The reason we don’t use 1" FL for regular cutting is the depth of focus is quite shallow- any light warpage and the spot is out of focus and becomes bigger than 0.2mm.

Also, even when perfectly focused, 1" FL cuts depth poorly because of some complicated aspects of how beam capture works with CO2 lasers.

Diode lasers are smaller spot size and can turn on/off faster than any rastering would even need. RF-CO2 lasers (Trotec, ULS, Epilog) can also operate at higher frequency than any rastering would need, and have no “minimum power”. If you put a 60W tube at 1% power, you legit get about 0.6W of stable output.

RF-CO2 is much more expensive initially, but much higher quality beam, and they last basically forever. And for the most part, a “worn out” tube is just gas leakage, it can just be re-gassed at Evergreen Laser and made new again.

Very well written explanation . Thank you for explaining the main difference with the RF-CO2 and why an Epilogue laser can have a lower stable output bs a Tube CO2

![]()