I have fox alien 4040-xe with 40w laser, I am having trouble cutting thru 3mm bass wood. I have made 4 passes at 10mm/m and 100% power. I set the laser with supplied spacer. Any ideas I am willing to listen. THANKS

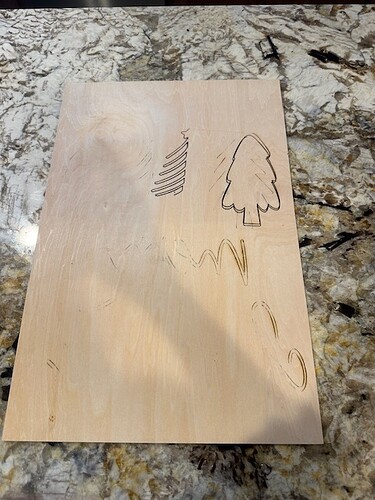

Photos help explain the issue.

Your wood is 3mm thick, and you focus on the top edge of the wood. Your laser is 3mm out of focus by the time it reaches the bottom edge.

I am not familiar with your laser, is 3mm out of focus significant?

I have seen videos where the same cuts thru 8mm.

I can do better. -Edited-

No Help! Thanks anyway

Not my best effort.- Edited -

I f this is the help that you get from this forum why would any body ask help.

Let’s all play nice, folks. ![]()

@dakota1 when you can, share a bit more about your setup for this job, best when you can share the project file (.LBRN / .LBRN2). This way, folks do not need to ask for each setting and how it has been configured, saves a lot of back and forth.

Additionally, sharing images of the results is also helpful during the diagnostic process. Occasionally, we can spot things that are not so obvious.

Your laser should be able to manage cutting 3mm bass wood without issue, so something is not right. The more you can share, the better.

Hi Dakota 1

I am new to LB and do not own a laser yet, so I can only say what I have read from other people.

Firstly, Is your laser lens clean and is the laser module perhaps moving too fast to actually cut the material?

Does it make any mark at all?

I tried to serch for this problem & how to share settings but I couldnt find anything in forum post and Docs (but I didnt spend a lot of time searching).

Some research & asking how to get help with sharing your settings and posting a picture is probably the best first move.

Kind regards

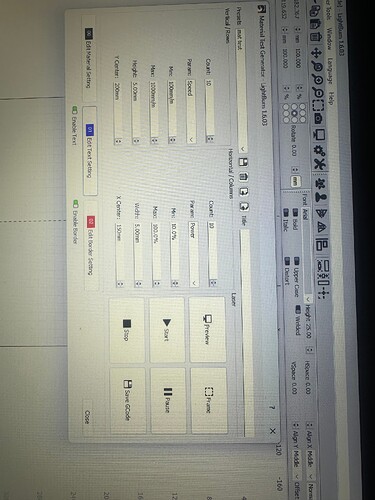

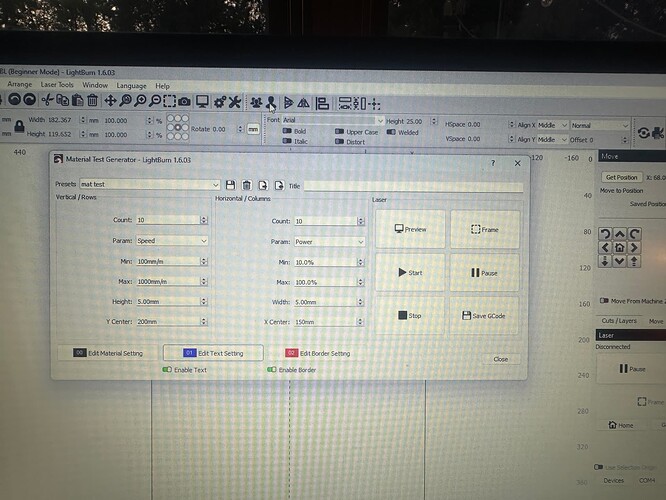

these are our settings and results (see attached)

the first pic is our settings

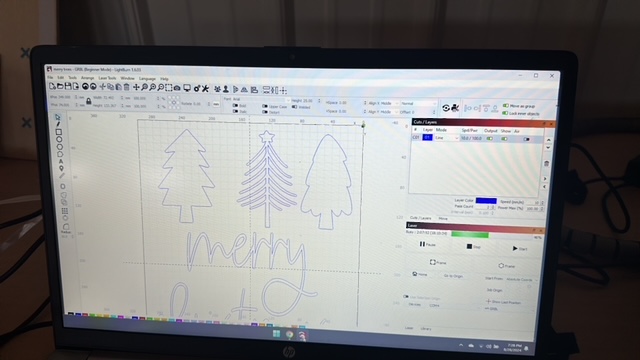

the second pic is front that took us 10 hrs and it didnt even go thu(second pic)

Laser work needs to be an incremental process.

Learn how to crawl before you try to walk.

Learn how to walk before you try to run.

One big thing for deep cuts - you have AIR ASSIST turned off. Deep cuts need good airflow to blow the smoke and ash out of the trench you are cutting. Do you have cross ventilation to draw smoke and debris out of the laser area? You need that in addition to AIR ASSIST to keep your laser lens clean and the smoke and debris out of the cut area.

Start with SMALL test projects. 10 hours is an obscene amount of time to invest in a process that you don’t have 99% confidence in. You will save tons of money, material and TIME if you develop your protocol before you dive into large projects.

Your screen shot pics are tough to read. Can you please post screen captures instead of cel phone pictures? Press (—EDITED—>)WIN+SHIFT+S to open the Snip tool. Then once in the forum window, press CTRL+V to paste. It really makes it easy to get good screen captures.

You also will get a lot more direct and pertinent help if you will load a sample of your Lightburn save file. Use this icon to open the file upload window…

- -

-

Hey Dakota

Looks like your almost there!

A few tweeks and undersandings and you’ll be having a Very merry Christmas!

Sorry I couldnt find that info for ya…it was very late here & had to crash.

Like James pointed out, you need your air assist getting the debris out of the way and the laser moving at the right speed “not too quick or too slow” Thats speed & power settings, and then how many times you repeat that cut " number of passes " so you dont try to do too much at once "That will cause the wood to char and make heavy burn mark…like you see in pic.

The number of passes is more for thicker wood and yr 40w is fixed focus so deep cuts & lots of power makes burns instead of cuts.

Its better for the people here if you figure out the “share settings” bit…like James said…they’ll put you right in quicktime and youll save yourself a bunch.

I would like to know how the back of the work has double lines on tree that are not on the front! and looks like a little kick in the ‘a’ at the 11 o’clock area.

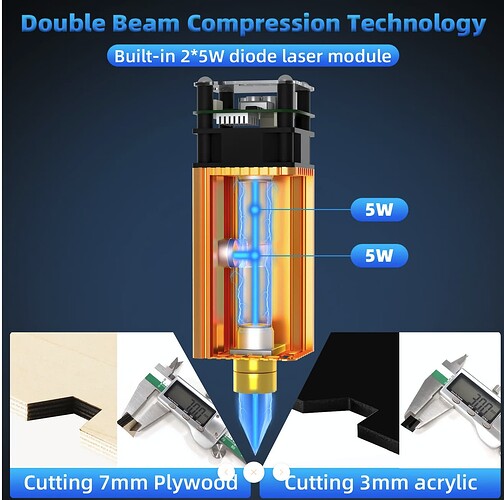

So this is a cnc with a laser module mounted correct? What laser module are you using out of curiosity?

A 40w diode should be blasting through 3mm at those settings easy assuming a few things.

- Your lens is clean and there isn’t any protective cover that you forgot to remove (it does happen)

- You are in-focus. You can run a focus ramp test to make sure what you think is in-focus actually is.

- You’re running air assist for your cuts. It makes a big difference.

- Your laser module is 40w output power. There was a rash of manufacturers rating by input power not actual output power.

- Provide airflow under your material and don’t place the work piece \directly on your CNC spoil board.

These are some of the things I’d start with.

I looked at that model last night…Think its a 10w optical.

First things first, there are a lot of companies who use this deceiving strategy of naming a laser by the electrical power rather than its optical power. FoxAlien 40w Diode Laser is one such product, the 40W is the electrical power consumption of the laser module while its optical / laser power output is 10W.

I am attaching images taken from FoxAlien website (CNC Router 4040-XE with 40W Laser and R57 Rotary Roller Kit – FoxAlien) .

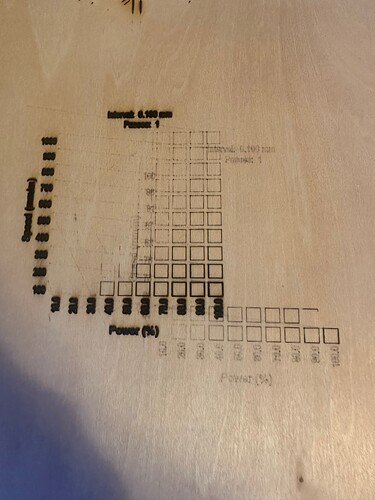

Regardless, a 10W laser cutter can definitely cut 3mm basswood. Lets start with a simple geometric shapes to figure out our settings rightly suggested by @JimNM . The same setting will hold mostly true for bigger ones like you have shared as well.

- Focus the laser head to the material with the focusing tool provided

- Connect and Switch on Air Assist at maximum setting

- Start by cutting a square of 1Inch by 1Inch with

Power - 100%

Speed - 300mm/min

Passes - 1

Ensure Air Assist Option slider is green in lightburn software as well.

Please share the images of the results so the community can help you out further ![]()

I got Longer Ray5 10W diode laser. According to my Cheat Sheet to cut 3mm basswood, you set speed 350 mm/min and 100% power to cut. And to engrave 3000 mm/min speed and 35% power. Do some material test and do your cut and engrave from the result.

One common issue is laser GRBL settings have $30 different from S-Value Max. Check and maybe set both 1000.

Another thing to consider is using multiple passes instead of a single pass. The result is cleaner and sometimes faster.

With my 10w laser, I cut 3mm ply at 700mm/m, 70% power, and 3 to 5 passes depending on the wood. And air assist is on.

did a light burn material test with speeds from 100mm to 1000mm and power of 10% to 100% still would not cut through