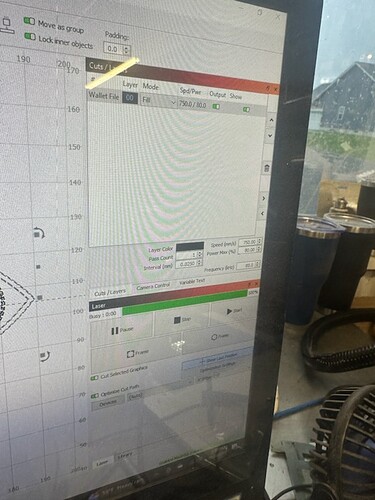

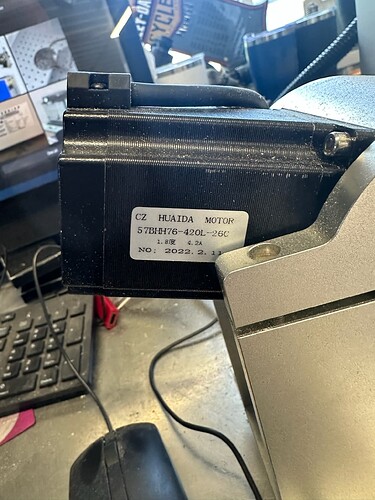

I just updated from a 30w fiber laser to a 50w fiber laser. The 50w came with the dip switches set to 1600spr, but would not move the rotary. I had to change it to 6400 to be able to test the rotary to spin. Now I am able to engrave on tumblers, but am getting squiggly lines. Do I need to make more adjustments with the dip switches?

I assume a chuck rotary?

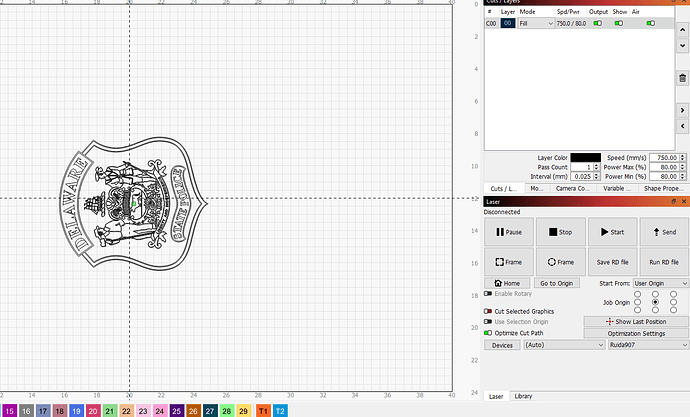

Steps/rotation should be good since it’s only a wavy line… Do you mind posting your project file so we can look at it’s design and how you are asking the machine to perform the operation.

It’s basically the same if it’s for any kind of laser engraver.

![]()

I had the 30w dialed in, so I am not sure if it’s the rotary motor with an issue or not? This rotary (Chuck) is the same style that was on the 30w.

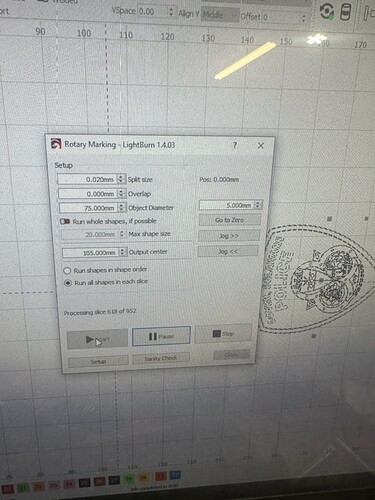

Split size should be either the interval or a multiple of the interval. It appears it’s not rotating right to me, so split size should be scrutinized.

Let us know if that does anything visible.

I use this procedure… seems to work ok for getting things lined up.

I buy this black masking tape… warp it around the object and set my power way down, so it just marks the tape…

Once it looks good on the tape, I remove the tape and change to the engrave settings.

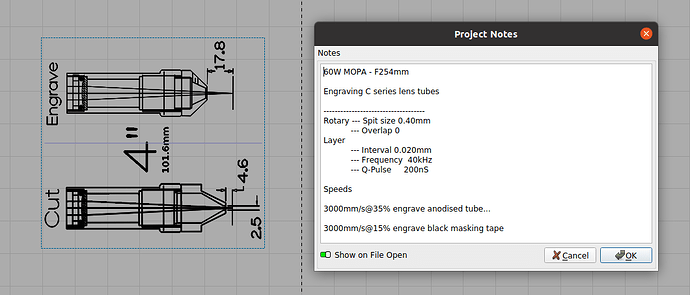

Use the project notes (File → Show Notes | ^ + shift + N) to keep settings handy… This is mine from doing lens tubes for the co2 on the fiber… It’s set to be displayed when the project is opened… Highly suggested…

Good luck…

![]()

Good morning. I am just now getting back to the rotary issue and figured I would give an update.

No matter what I do in lightburn, the angled lines are wavy. I am going to take my rotary to another friend’s house who has a fiber laser as well to see if the rotary is the issue.

If you can do that, it would eliminate the device. I doubt it’s the rotary… this has to look of something not quite right. A digital machine usually just fails, not limp along.

No difference with the split size/interval values?

Good luck…

![]()

I have tried the different splits and line intervals and no change. When I had my 30w fiber laser, I had no issues at all setting up the rotary. Definitely crazy to have the issues. Hope to figure it out soon.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.