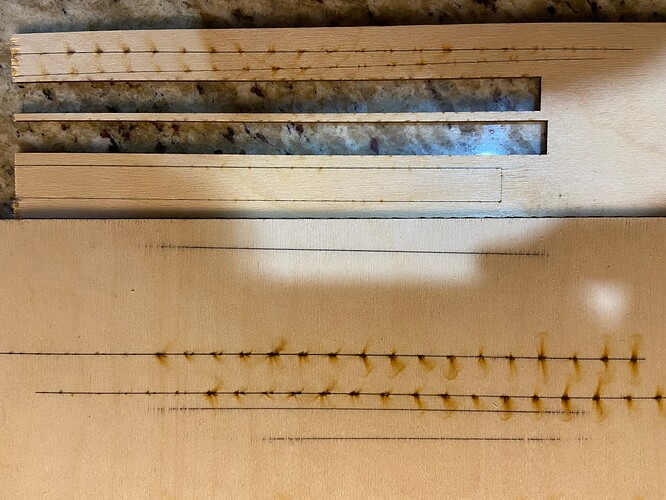

my 6 year old 80 watt CO2 laser needs constant power changes, cuts fine, next cut need another 20% or so power increase and flickers. How do I tell if the power supply or the tube is defective. On bottom of all cuts good or partial cuts I can see brown pulse burns approx. every half inch and never had that before.

If I had a co2 laser, I would always keep an extra power supply around so that I could swap it if needed. Have you inspected your wiring to make sure everything is connected properly? Please post photos of your laser’s output so that we can better confirm what’s happening.

are you asking for a photo showing the amp meter draw while cutting ?

It wouldn’t hurt to look at the amp meter while its engraving to confirm its a power issue. I was more interested in seeing what the burn looked like. An example of your laser burning as you’ve described

ok,I will check all wiring at the power supply and the laser tube, thenwill try to send you a pic of the underside incompleted burn showing what appears to be pulses type burn mark. will get back to you later

thank youTom

wiring all seems to be tight and nothing loose.

you can see the pulses as burn marks,

the anmeter when cutting shows a constant needle movement and is steady, not fluxuating. (27Ma for the 1/4" cut

when I cut 1/4" russian plywood my settings are .4 inch/second at 80% ower

when cutting 1/8" same material my settings are .9 inch & 35-50 % power.

Im trying to figure out if my power supply or laser tube is causing the non dependable power settings , which is defective.

I was hoping to get some advise on what people think what the problem is. I am wondering if the poor cuts are due to defective power supply or is it my laser tube going defective

That’s my bet, if only because it’s relatively cheap and easy to replace. The tube is a whole 'nother level of annoyance.

Frankly, if the machine needs a new tube (which is possible after six years) you’ll want to replace the supply at the same time, so you may as well start with the supply and see if that makes the problem Go Away™. If not, then you replace the tube with a new supply already installed.

What you’re asking is how to I determine if it’s the tube or the supply.

Unfortunately, there is no easy way to determine that. There is no easy way to test the hv out of the lps or how it relates to tube operation without specific instruments most of us do not own.

I’d suggest you check the tube resonance or mode, if that’s bad, you need a new tube. This manifests in many ways, so a quick check will tell you one way or the other. If it’s not in TEM00 mode, it will never work properly.

When I replaced my tube, I didn’t replace the lps… I don’t have deep pockets, so I prefer to troubleshoot it down to the Optimum Replaceable Unit (ORU) i.e. tube or lps. Not replace them as a set… I don’t trust Chinese replacement parts that well… might end up with something worse.

In reality, if the tube appears to be in TEM00 mode usually means tubes OK, then it’s an lps.

If not in the proper mode, change out the tube as you will have to anyway.

Hope this helps

![]()

I plan on purchasing a new power supply for this 80 watt CO2 laser. Does anyone know of a Canadian CO2 laser part supplier preferably in Ontario

ordered and installed a new power supply. cutting seems much better with lower power setting, ran for about 20 minutes while cutting and then noticed the carriage was no longer working while cutting new job… I will start a new thread now to find a solution to this new problem.