If you have

- properly working tube

- aligned and clean optics

- proper focus

It will work, so one of these is having a problem.

A proper alignment should start at m1 (mirror 1) examining the beam quality from the source (tube). This should resonate in TEM00 mode or it never will align properly.

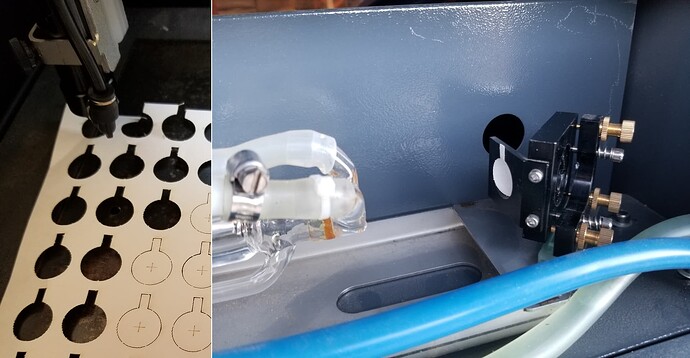

I cut targets out of watercolor paper so I can press fit them into the mirror holders.

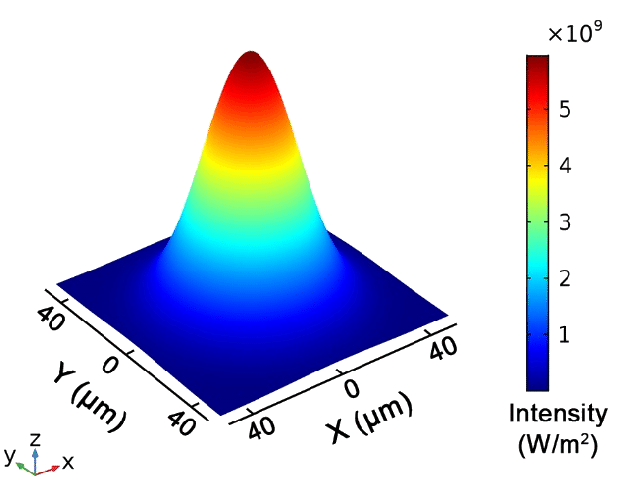

The burn mark needs to be light enough to see the Gaussian power distribution curve across the beam. A picture of a hole is of little use. Generally lighter is more informative than darker.

Here is the curve … it should have more power in the center… you should be able to get a good cross section on your target.

We might not think of this as machining, but it is in the sense we are removing material by some type of tool… Both additive and substantive machining can do the job at a great variety of values, known as speed/feeds, however there is a small area of these values that works best with that tool and material. Meaning less energy, tool/machine wear and better results of the end product. I’m sure you’ve seen this.

For metal or man made materials cutting with spindles and bits you can compute the speeds/feeds for that item… When using naturally made materials and lasers it’s not so simple because we don’t have sufficient data on either the tool or the material. We can only control with accuracy the feed rate.

Speed usually relates to the tool spindle, with lasers it more like percent power and feed is how fast the material/head move by each other.

What I try to do is run at the maximum comfortable power at the fastest speed that will do the job.

This seems to give the best results for me and it what I commonly do.

I’d love to just be able to tell you the sweet spot, but alas I cannot. ![]()

Does any of this make sense?

The Reci is a good tube, a grade A Reci, if that’s what you have … I’d expect 5 years (10K hours) of commercial use before a failure… There are lots of variable here, but your symptoms look like the tube is going south.

Good luck

![]()