Back to our regular programming…

With this post I presented a way to do 2-“color” glass engraving using my litte 2.3W Eleksmaker laser module…

so I decided to see if I could duplicate the process using the $79 Cenoz laser engraver.

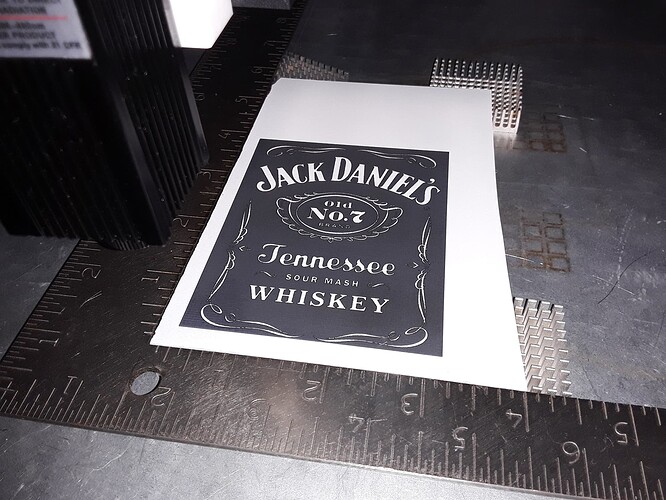

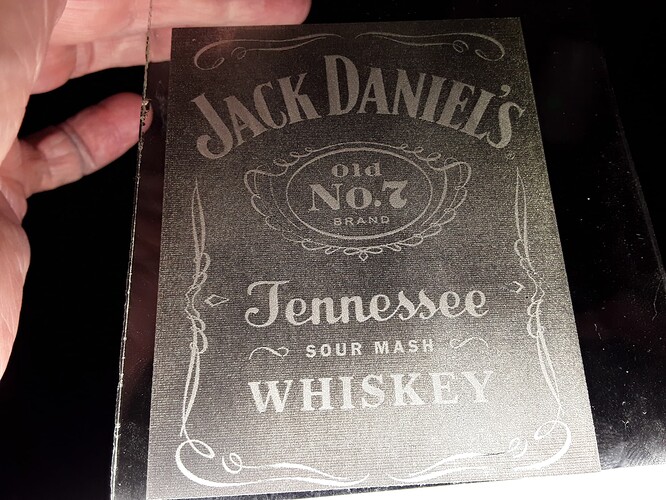

Flat-white paint on glass is lasered with iconic JD label to give black/dark markings on glass…

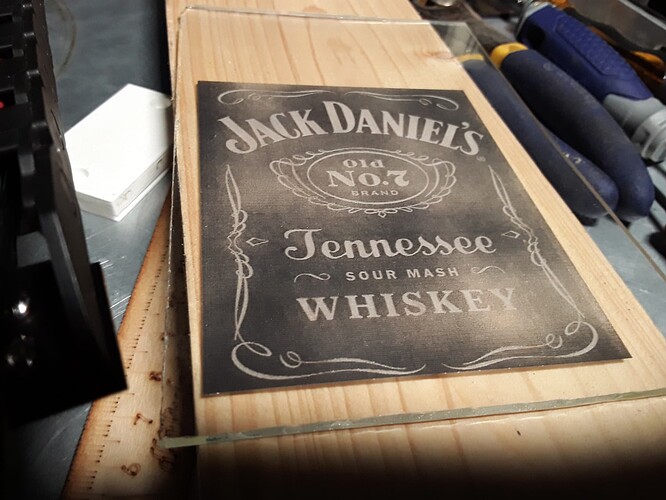

White paint is completely removed with acetone. Black tempera paint applied and lasered to give frosted marking on glass… registration is crucial…

Tempera paint removed with water and dish-soap…

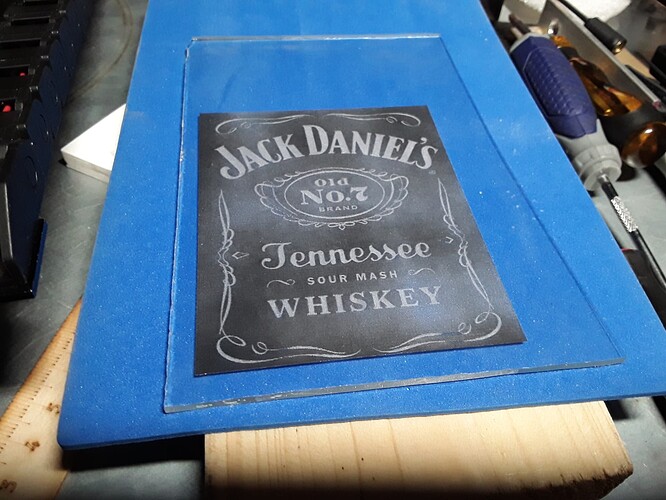

The black markings are not as black and distinct as the original ones above. I’m not yet sure whether it’s a paint/coating thing and/or possibly not finding/using optimal speed/power settings (I used the same setttings as for my 2.3W laser) for this laser. The process is still valid however… I need to do a couple of NWT test grids using the Cenoz laser to see if I can get a better result.

– David