Carrying on, as if I knew what I was doing…

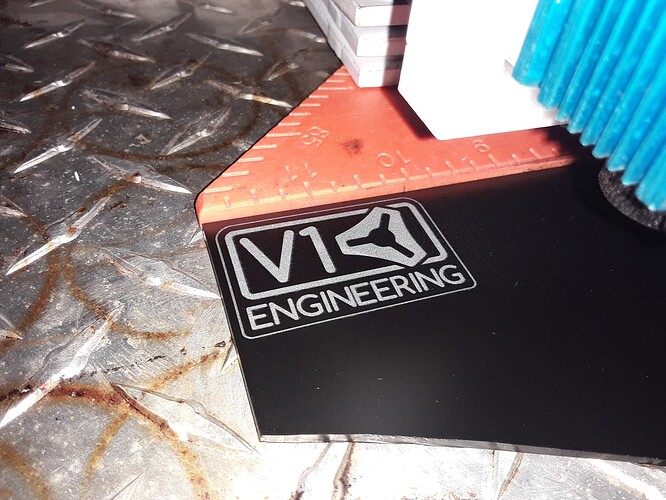

Prepared 2 gcode files in LightBurn… one for black paint (bottom), one for white paint (top)…

Black painted glass, lasered areas should be frosted/white…

After cleaning off the black paint, painted glass white, lasered background should be black…

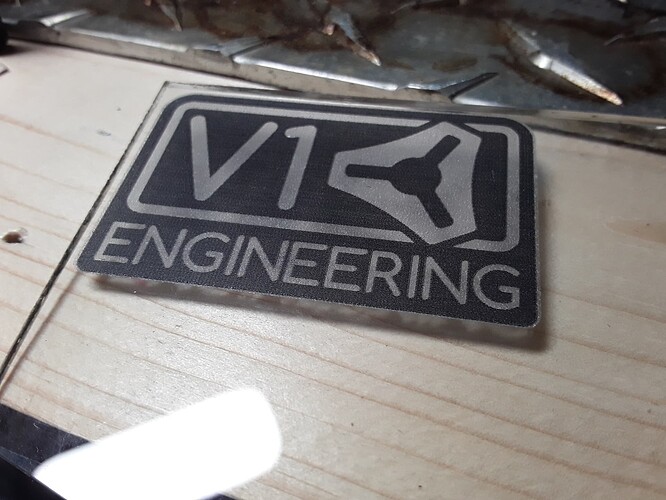

After removing all paint with acetone… leaves two-“color” logo

Edge-lit, the black background actually appears to have a frosty texture… not sure why. Possibly changing the order of operations might have an effect?

I’m reasonably pleased with the result… ![]()

– David