I don’t remember the name of that place off hand. The stuff they make, they have 80% of world market.

When your employees are happy, you are happy and everyone makes more money. I remember the GM pointed out an old black gentleman , (white hair, beard and and appeared really frail) the Gm said that he was the very first employee hired in the house cleaning dept. Today he is the senior manager of house cleaning dept. and is one of their wealthiest employees. That meant the old man had been for around 30 years when I was there.

Randy

Have to say, i’ve enjoyed reading your stories.

Been a laugh ![]()

![]()

Just thought, forgotten what the thread was about ![]()

Yeah, it got a little side tracked there toward the end.

Thanx,

Jim

Did something similar for a class with Simone Giertz. Logos are made using the inside/outside kerf settings to get a nice inlay fit. Box is laser cut 6mm Baltic Birch covered in fabric. Insets are Harbor Freight foam floor tiles with felt adhered with 3M Super 74 FoamFast. Logos are the same floor tiles with 1mm EVA color foam adhered.

I’ve referred a lot of people to this article from some Facebook Groups that I help support, and they always ask what material I used. It wasn’t until today that I realized it was never part of this thread… so I thought I’d pop it in here:

EVA floor mats.

Or you could use Harbor Freight floor tiles that are a bit cheaper, but not as thick.

https://www.amazon.com/gp/product/B01DAOSLVM?th=1

Jim

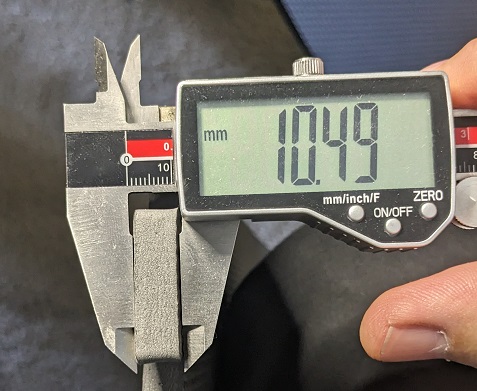

Amzn .375" $22, H.F. .5" $10, just checked.

Great project for the laser. My next door neighbor asked “what can you do with it?”, yesterday. I need to make a spreadsheet listing all the things you can do with a laser, in case I am asked again.

There may have been some changes to either product, but I still have both on hand.

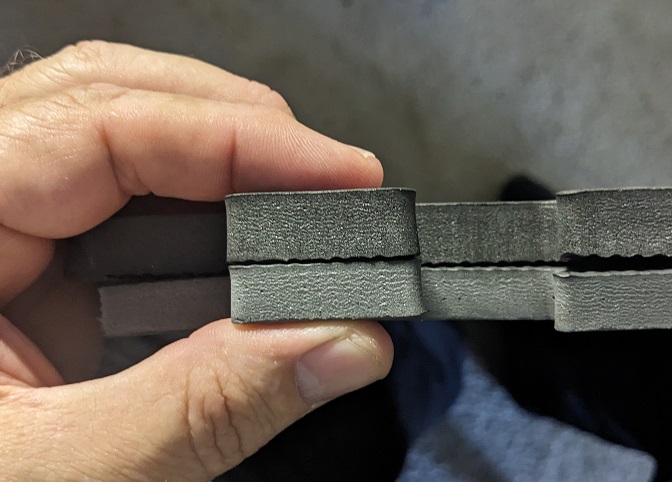

Harbor Freight product is on the bottom:

Amazon:

Harbor Freight:

Buyer beware… the product I ordered (from that link) did not previously say .375 inch thick… I’m pretty sure it said 12mm, which is why I chose it. I already had HF stock on hand, but wanted something deeper.

Just sayin’

Jim

Just checked my H.F. mats and they are the same as yours, maybe even a bit thinner. How about this, buy the half-priced H.F. foam and cut 2 layers? That way you get 3/4" foam?

Just wanted to say “Thank you!” As a habitually messy person, but who just so happens to be re-organizing my took cabinet at the same time that I’m learning Lightroom and testing out my first laser… this is genius and perfect timing!

You’re welcome, I’m glad you enjoyed the thread.

Jim

This is the primary reason that I purchased my Laser Engraver (although I convinced the wife that she wanted it for cups). I thought the process of converting all my random tools to shapes would be a lot of work. Looks like it’s going to be pretty easy with my iPhone and that backlight pad (which I already have on my desk). I’ll be making custom boxes out of recycled Amazon cardboard.

This is so great to hear. I’m glad this information inspired you (that’s what we’ll tell her anyway).

Good health and good cutting.

Jim

Jim,

I was so impressed with your ides of backlit processing that i went out and bought the same backlit you have. Very nice LED unit. Price was descent too.

Thanks for contributing

Pelogius

Hi Jim- I also use toolKaiser but I’m having a problem importing the file into Lightburn.

After I edit and adjust the item in toolKaiser and send it to Lightburn, the saved item is a lot smaller (22 to 28% smaller) then the actual size. I am saving my work in toolKaiser as a DXF file. Any suggestions or feedback would be appreciated.

Toolkaiser was too cumbersome for me… that’s why I just do the tool profiles myself. The same strategy applies though… measure a known dimension on the tool, and then scale the lightburn geometry to match… regardless of how the silhouette got there.

Jim

Got it! Thank you for the reply!

A daycare might be interested in the cutouts - especially if you make a little toolbox to put the “tools” in ![]()

Thanks for sharing this idea. I’m in the process of creating a replacement foam insert for an old set of tools. The set is old enough that the foam disintegrated. This will make the outline creation a lot faster. ![]()

A great idea Marilyn, but in today’s world, I’d be named at the top of the lawsuit (along with the foam mat manufacturer, the laser manufacturer, the daycare, and anyone else who happened to be walking by) because some child choked on the chewed off end of the pliers, etc… etc… As much as I would love to do what you suggested… the risk today is not worth the reward anymore.

Jim

I’m sorry. I didn’t even think of that. It’s crazy how things have gotten.