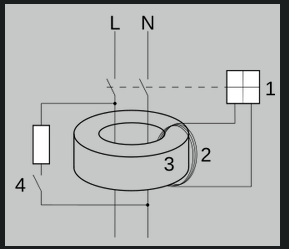

I can’t finish my post on grounding and emi waves (if an administrator can contact me, so I will continue my post here. As asked here is how I filtered the EMI, using ferrites, they simply clip near the connector you want to isolate.

Here at the outlet of my power supply.

.

I did the same for air assist etc. By the way I switched to a high quality OFC copper shielded USB cable quality.

I received my new 4A power supply, which completely removed my worries about stopping in the middle of work. In fact when I engraved at 70% of power all the work stopped without reason, suddenly problem solved BUT

There is still a GOAL…

I focused on the original power supply, which being undersized, I discovered a major concern and DANGEROUS!

here is the socket for the new 4A power supply.

Standard socket with a well-sized three-conductor cable, 1 phase, a neutral and an earth.

Let’s compare to the original shot!

One side seems normal, three holes supposed to be 1 phase, a neutral and an earth, BUT it is vicious and dangerous as desired,

Look at the other side, the power outlet, a phase, a neutral and OOPS no earth!

What would happen if there was a problem, overheating, electrocution, fire?

I am lucky my home is equipped with a differential circuit breaker (mandatory in France, but especially old homes are very often without one), which would prevent me from electrocution or a fire, before I could feel anything, I tested with a nail driven into the socket (don’t do that at home or anywhere else!!!) I am still alive because the differential cut the electricity in 1/1000th of a second.

In short, all this to say that the machines are often sold for savings, with power supplies specially sized in amperage, unfiltered, not EMI shielded, and without grounding! To good readers.