Your wired up wrong if the LED varies in intensity. It should be on or off, it’s not analog. If the diode was in backwards it would just conduct and burn up. I don’t use diodes in mine and I can feel the solenoid ‘switch’ mechanically when it’s energized.

Dave is correct, the ‘wind’ is a ‘sink’ for the 24V. As he is about the operational limits of the pneumatic solenoid.

I know this is an issue with Cloudrays Ultimate Air Assist (UAA) kits, maybe it’s related? Some type of problem with the valves they supply.

Lightburn sends air assist “on” but does not send air assist “Off”

Part of the issue, is we can’t see what the wires on the solenoid are, where they go or anything that is of much help.

What wire is blue, what is red and what is black, what are their functions. Colors are meaningless without some kind of interpretation. Is the board on the solenoid marked with something useful to help identify what wire is used for what? Probably red is positive…

ASSUMING red is +, it’s a very simple wiring only requiring 2 connections, + goes to 24v and - goes to wind. Whether the blue or black is “-” is the question.

However you hook it up, The LED indicates it’s activated and the solenoid should be energized. It’s not a ‘power’ indicator as so many ‘hobby’ pcbs have. So it should be off if it’s not enabled by ‘air assist’ on that layer.

From what I know about the UAA that this relay appears to be the initial relay to allow air into the machine, which is usually connected to the “Status” (or ‘run’) sink.

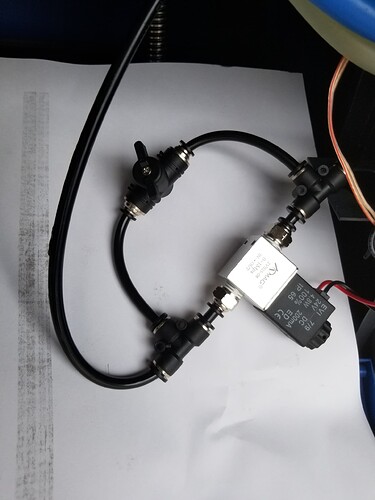

This is the bypass solenoid on mine.