I recently converted my MonPort to use ShopAir, with the wind ouput of the Rudia controller driving a relay to turn air on and off. The problem is that instead of running air for the duration of the job and just leaving it on, it turns it off every time the laser turns off to do a travel move. So in cases like text engraving where the laser is turning on and off a lot, the relay is being rapidly toggled and this is going to shorten the life of the relay for no good reason. It makes no sense to be turning off air for all these short little moves. Is there a setting in LightBurn or on the Rudia controller to keep air on unti the job completes?

Can you add a capacitor or two in line between the ruida and the relay? That would keep the signal wire powered for a short duration during the rapid moves.

led - quick charge but slow discharge of a capacitor - Electrical Engineering Stack Exchange

The machine console has a screen for Aux Air settings (or something similar), with confusing choices. The one you want is whatever it’s not set for now; my KN332N works with Blow when cutting.

More words & pix on my assist air setup with the KT332N:

The words in the manual do not match the words on the console display, so it’s something of a puzzle to match what you want with what you see and what you get.

Thanks! Hey, I think I recognize your picture. Are you the same guy who was on the MakerGear M2 forum alot about 7 years ago? Same guy who wrote a book on TSR programming?

I thought about doing that with the capacitor, or even making a little one shot circuit that keeps the relay closed for a minimum duration before allowing it open again.

Yeah, although those were definitely brighter versions of me.

![]()

Wow, small world! Here we are both playing with lasers now. I went from M2 to Prusa and now Bambu. Been doing 3D printing extensively since the M2 days, but am just starting out on lasers.

IMHO, I don’t wouldn’t suggest a hack to fix a configuration problem. As an in line connection to the Ruida, this will prevent it from working at all.

These aren’t cheap Chinese spinoffs, they are used commercially all over the world … without the hacks.

These things work, and as @ednisley mentioned, it’s more than likely it wasn’t configured correctly.

There are some versions of RDWorks that allow changing this. What @ednisley didn’t mention, was this usually requires a password… at least it does on mine.

![]()

Aha - I thought it was a self-installed “hack”. Again, the Dunning-Krueger is strong in me.

Cheers!

Yes, I ran up against the password on mine as well and didn’t get beyond that. According to the manual you create the password the first time, but I see no evidence of this being possible. If I select numbers and hit enter for each one until the password field is filled, the last enter just generates a “Password Error.” Seems like that would indicate the password has already been created and you didn’t match what it should be.

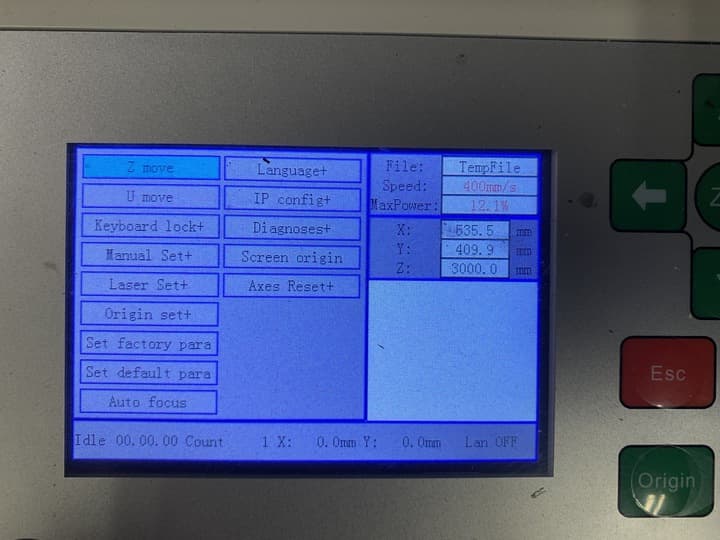

So I did some password research and found one that works, but it did not take me to a config screen. I think all it did was reset to factory settings, which means I’ll probably have to go in and turn air assist back on. My control screen looks like this:

That looks like a 6442, but perusing the manual doesn’t produce anything other than the simple enable you already found.

It may be the 6442 doesn’t have that setting, in which case a timing module may help:

https://www.amazon.com/DROK-Controller-Delay-off-0-01s-9999mins-Switching/dp/B07DFT2WDS

I think mode P2 is what you want, where each input signal during operation retriggers the timer. For sure, it’ll take some playing around to sort out all the polarities and intervals.

Great, that’s certainly better than buying a monostable multivibrator from Digikey and trying to roll my own (which was my original plan). Seems like there is an off-the-shelf circuit for everything these days. P2 does indeed look like the desired mode. Thanks for the help!

AFAICT, entire factories now turn out small circuit boards implementing all those semiconductor App Note diagrams we used to solder together. ![]()

Yeah, even the Arduinos that are so popular now are basically what we called “evaluation boards” back in the 90s. Granted they are a bit more than that software wise, but the hardware is basically the same.

If it did a factory reset, then it wiped the vendor configuration back to it’s factory set default.

Did you make a backup of the Ruida configuration?

I’d suggest you find a version of RDWorks that will allow the change and use it… I’d prefer the device work as intended not apply some hack…

Of course it’s your machine ![]()

What password worked? Which option did you pick?

![]()

I was worried about that, since the manual was incredibly vague and it was only after entering the password that it became apparent exactly what the operation did (password was HF8888). So I though I hosed myself bad, but when I run the machine everything still seems to work as it should. It homes in the right corner, sees the limit switches correctly, cuts accurate dimensions etc. The menu option I picked was the “Set Factory Para” one, which I later found out resets to vendor configuration like you said. Perhaps the vendor config and what the machine required were one and the same? I don’t know, but it is working (except for the air assist, I think it did revert to having that turned off).

The way I see it, there is a much higher probability of me screwing up the machine trying to install a new version of firmware on it than putting a pulse stretcher on an output line that nothing else is using other than my own installed relay. If “hack” is defined as changing the machine from what the vendor sent me, then both of those solutions are hacks. One is just safer because it doesn’t alter anything that the machine is currently using.

I don’t agree that it’s a hack to change the supplied configuration or they’d call this hacking every time we changed something… Like, just using a rotary, I don’t consider a hack.

If the machine allows you to change the controllers configuration, then you are doing what the manufacturer is OK with or you couldn’t change it.

Why add additional hardware when, with the proper configuration, as engineered it will do what you want?

I have hacked mine… different head, tube holder, power switching and change the way the machine engages the drive belt. These, I’d call hacks… Makes many things much easier on me.

It’s your machine, do what you want… if you want to call a configuration change a hack… have at it.

We just agree to disagree… no perspiration.

![]()

“I’d suggest you find a version of RDWorks that will allow the change and use it”

Maybe I’m misinterpreting what that means, but isn’t RDWorks the firmware the the controller is running? If my current version doesn’t allow the desired configuration change, then an entirely new one would have to be installed. I’ve already had a near miss with screwing up the machine trying to do this the configuration way, I don’t want to risk another one. The Rudia UI is already scary-bad in that it lets you wipe your machines settings without so much as a message telling you what you are about to do and a way to back out of it. I’m wondering if maybe MonPort set the factory settings to their own settings in order to prevent this kind of disaster, and the tech support burden it would cause.

Well, having looked in the 6442 manual and, to my astonishment, not found the expected blow / wind / air setting controlling that particular function, I assumed it’s not there and other solutions were in order.

Which is not the first time I’ve been dead wrong in public and, in fact, more poking around suggests it’s a configuration available only through RDWorks, not the console:

Whether that’s the solution or not, I cannot say, but I’d haul out the Token Windows Laptop, install RDWorks, and see what options it exposes. There’s a first time for everything …

![[06] RuiDa Controller - Setting the Air Assist Blowing Modes -RDC644X - RDWorks](https://img.youtube.com/vi/ZbCbLGymNhg/maxresdefault.jpg)