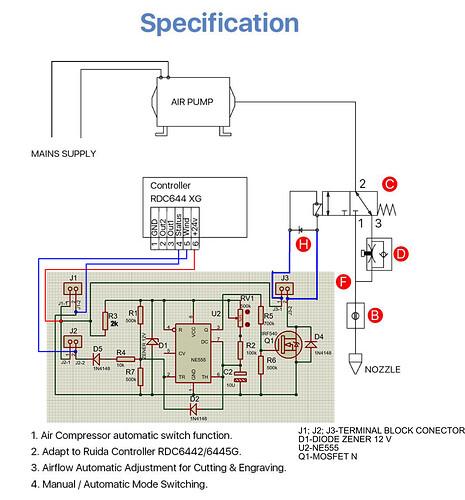

This electronic scheme solves the problem mentioned above and discussed on another topic Air assist solenoid fires rapidly on RDC6445G - #39 by Stroonzo

There are 2 modes for Auto Air Assist Solenoid Valve:

1 Blowing while LASER ON - this solenoid will click on and off each time the laser fires.

2 Blowing while PROCESSING - this will click solenoid on and off for each mode set in the layers if Blowing Yes or No. The solenoid valve opens throughout the working process. This is the preferred mode.

For me, only method 1 works and it’s a big problem. Because of this I made this electronic scheme, it has a delay of 5 sec (or longer because it is adjustable) when closing the solenoid valve. I did a virtual simulation and it behaves perfectly, I will implement it in the next few days and I will come back with information.