I suppose it will not hurt if it is in there. Good to know I can install it “downstream” of the preinstalled wires of the solenoid.

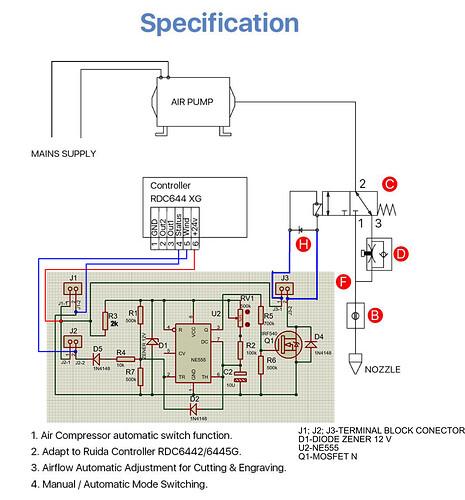

I managed to make an electronic scheme that will open the solenoid valve throughout the cutting/engraving process. This installation will allow me to connect the solenoid valve to terminal 5 WIND and to have the ‘Air Assist’ function operable. This electronic scheme will open the solenoid valve quickly when the cutting/engraving process begins and will close 5 seconds late after the process. The delay time can be modified according to everyone’s preference. For me and for other people who have problems with opening the valve intermittently, it will be the best solution. I hope you understood why I choose this method, I also tried RDWorks and it doesn’t open continuously and I don’t do firmware for Ruida, I’m afraid and I don’t even know if it will solve the problem. If you want me to upload the electronic scheme, please tell me, it is at the project level and it behaved excellently on the virtual simulation.

Sure, upload the schematic.

The basic air assist, schematic way up there, works fine.

I guess I don’t understand your issue.

What/why are you changing it’s basic operation?

Lots of people have valid reasons for things, I assume you do to and this is and ‘educational’ forum.

This electronic scheme solves the problem mentioned above and discussed on another topic Air assist solenoid fires rapidly on RDC6445G - #39 by Stroonzo

There are 2 modes for Auto Air Assist Solenoid Valve:

1 Blowing while LASER ON - this solenoid will click on and off each time the laser fires.

2 Blowing while PROCESSING - this will click solenoid on and off for each mode set in the layers if Blowing Yes or No. The solenoid valve opens throughout the working process. This is the preferred mode.

For me, only method 1 works and it’s a big problem. Because of this I made this electronic scheme, it has a delay of 5 sec (or longer because it is adjustable) when closing the solenoid valve. I did a virtual simulation and it behaves perfectly, I will implement it in the next few days and I will come back with information.

Looks great, let us know how it works out.

There are others that may wish to duplicate your ‘fix’.

Any additional information is good…

I noticed that there are many people with this problem. I’m going to do tests on the breadboard and come back with results.

I did tests and everything is perfect. We installed two LEDs to understand the usefulness of this electronic installation. The green LED indicates the voltage at the PIN 5 WIND terminal and the red LED indicates the voltage that supplies the solenoid valve. With this electronic assembly you have the operational ‘Air Assist’ function and the solenoid valve will be open continuously throughout the cutting/engraving work. I’m going to make a PCB and put it in a box made of transparent acrylic.

IMG_20211104_003056_9|375x500

Processing: VID_20211104_002830.mp4…

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.