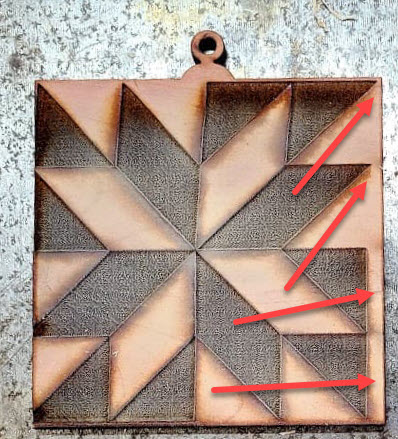

This looks like something else. If you’re willing, and if you’d be so kind as to arrange the four produced parts as they were on the screen in LightBurn and work with me to verify something.

If the ‘drift’ is happening and if it stacks-up (gets additively worse) in the direction of the back and forth fill-engraving It can be a known hurdle with how the engraver is controlled.

Cutting out a job is a vector process so it’s almost immune to this. Engraving the pattern is a raster process sometimes called a scanning process - it’s the least immune to this. The end result is that if the leading edge / trailing edge is set incorrectly it can move the raster stuff away from correct as the job progresses leaving the vector stuff in place.

With all four components organized as they were when they were being produced, please measure the distance between the edges of the art (left-right) and the cut out border. If it gets worse as time progresses, it can be this:

I’m optimistic that you’ll help everyone understand what’s going on here and that you are similarly interested in answering a few diagnostic questions.

I will move your thread to its own location so your request gets the attention it deserves.