Typically, this indicates one of the limit switches (or focus switch) has been physically tripped. 6 on this machine, I believe. Most are well hidden. Double check all wire routing (may not be readily visible) and mechanicals with laser at every conceivable position. Also verify material is flat enough to not contact focusing button during normal operation.

Issue ended up being a screw that came out inside the rail that holds laser. It’s working now. I have the autofocus macro configured in lightburn that I use. Now, I’m working on testing speed, power and trying to get straight nice cuts. Tonight the garage got pretty smoky, so definitely need to read and watch more vid’s. Especially the kerf (SMH). I didn’t realize what I was getting into. LOL. Just going to take time and tests.

You’ll definitely want to invest in an enclosure and exhaust system to get the smoke outside. Some woods and processes produce copious amounts of smoke that are bad for both you and the machine.

“Straight, nice cuts”… ? Got any pics of what you’re currently seeing? That machine is quite capable of producing accurate geometry once properly set up. Mine required a fair bit of “tuning”. Lots of loose screws, rods, floppy belts, etc…

Oh, also NEVER use the “fast” mode (from the touchscreen). Even with the mechanicals tuned up nice, it introduces a lot of “wobble” around direction changes. Normal" works pretty good.

You’re definitely going to need air assist to keep the lense and nozzle cleaner for longer. And while it’s possible to use it outdoors you really do need an enclosure and extractor fan (I’m planning to make one myself from corruflute and velcro - you can buy one I guess but they are very expensive for what they are. Plus a cheap bathroom extractor fan and flexy duct from the diy store).

I used a small collapsible “grow tent” for my first temp enclosure. It was a “cool grows” brand from Amazon. I think it was like $50. Used a.200cfm AC Infinity blower with it (still using). Tent worked fine, but the zipper door was a pain. Plenty good for a quick, cheap temp fix.

cggorman [Chris] Can you message me directly on here? I have some photos and curious what tuning you did. I’ve done material testing, and auto focus. I’m sure a lot of my issue is with speed/temp and kerf. Ive watched so many videos and material tests, nothing is cutting nice and straight. Small circles look like pin holes, or nothing at all. This new template I have is pretty simple and should easily cut with no issues. Especially being 1/8" underlayment. I tired a simple logo last night on same material and the sharp edges are a bit rounded and/or extremely burnt. (anyone that asks, yes i have done tons of material testing)

We could message privately, but I could barely fill a thimble with my knowledge. Many others here have full glasses. I’d suggest starting a new topic and share with the community. You’ll get good info more quickly.

Anything unique to the K1 or Atezr L2…same machine…(like engrave mode) may be more limited knowledge but few issues are truly unique.

I’m headed to bed, but feel free to search “Atezr” or “Ikier” and my handle if you have time. Most everything I’ve discovered about these two machines is here somewhere.

Sounds good. Thanks.

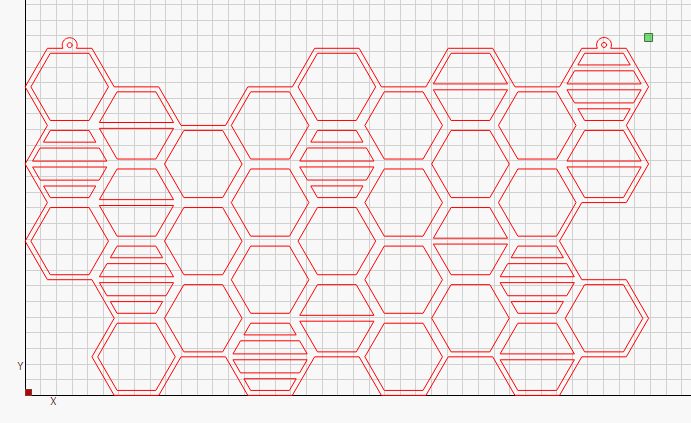

This is what I got. It took about 5 mins…but then again, I have been using Lightburn for 4 years. There is a HEXAGON shape tool and just make it the size you want and then I offset it .125" and then DUPLICATE (Right mouse → Duplicate) and then move and places. For the horizontal patterns, I just drew a rectangle with the rectangle/square tool, duplicated it 3 times and moved them. I then used the boolean subtract .tool.

I would suggest looking up on YouTube “Lightburn 101”…there are many there and that is where you will get the most help.

Honey comb.lbrn2 (81.8 KB)

There is a trace function. Here is something quick I came up with. You will have to learn about nodes. I’ve used Lightburn for about 2 months and it’s a great program. Learning about nodes really helped me fine tune my creations. So this is a start for you.

P.S.

This isn’t a really ambitious first project it’s a great start. I have the Atomstack X7 pro 10watt and love it. It’s paid for itself and bought me a laptop and Lightburn within a year without even trying to sell things. My motto is if you are going to practice do it with projects that sell so you can get the best of both worlds.

I hope this helps and I hope the file goes through. This is the first time sending a file through this chat.

Cheers

Steve

HoboWithWood just released a new YouTube on node editing that covers it pretty well for beginners at node editing.

I recieved it. Thank you. My honeycomb bed is currently out for delivery so I will be giving my it try again. I have’t had anything holding the wood in place and i think my last one i tried, it moved. I’ve received great advice from here and other forums as well. My speed and power seem to be ok. my workspace is 401mm x 410mm and this project is just a bit smaller than that. I’ve resized it, and I’ve checked all my settings. Hopefully with the 500mm x 500mm bed and holder tabs, i will finally have a successful cut tonight.

Chris

I am late to the conversation but I did want to suggest that you check out

Hobo With Wood on YouTube. There are a lot of great laser channels on YT but Steve has a way of teaching that is perfect for a beginner (Like Me). He has recently done a video about using the “array tool” which is exactly what you needed for this project.

Exactly…this makes or breaks the effectiveness.

![]()

Thank you for the info. I’m going to check out these videos tonight. I appreciate it.

Sell the Atezr… The customer service I have received on mine ( or lack there of ) has made this machine a NIGHTMARE… I believe the machine has potential, but getting help from them is totally useless… I only pray you have better luck with them than I have.

I’m a high school teacher and am trying to set up an Atzer that admin bought a year or two ago. No one can find the flash drive or TF/microSD card with the config file, and I can’t find any config files online.

If anyone has the V35 and can help me with a config, I would very much appreciate. I also don’t know if I’ll be able to find/install the relevant drivers since Atzer no longer has a website, and it doesn’t look like many of their files have been mirrored elsewhere.

Download the files in this post (400MB):

It looks like that has drivers (but maybe only for Win7/Win8?), and I still can’t find a .lbdev config file (I was told that I need one before I can start using lightburn with my machine (V35 Plus))

Check if this one works for you.

After download just drag over Lightburn window to auto-import.

ATEZR_.lbdev (3.2 KB)