I’m trying to use a Atomstack R1 rotary chuck on my Commarker B4 20W Fiber. Then driver box it plugs into is a DM542 and I’m running windows 11. I’ve tried most settings for the different stepper settings in the DM542. I set the rotation steps on the rotary setting and I get a full 360 on the tumbler. When I burn a image it is only half the size, example if I make a 20mm box it burns at 10mm. Is something not right or do I just adjust the steps on the rotary to make the burn the correct size and ignore the original setting to get it to 360/rotation.

You don’t mention if it’s a chuck or roller rotary.

Sounds like you don’t have the steps/rotation set correctly.

If the issues it setting the DM542 module up, please advise.

If you still have issues, sing out ![]()

![]()

It is a chuck style rotary, just confused why I enter the steps in the rotary setup in lightburn and run the test it gets a perfect 360. When I burn a image its half the size it should be. I was just curious if there was another settings menu somewhere I had to change something.

Have you ensured that the rotary is enabled in Lightburn?

If the test button in the gui works, then the rotary is working and is set properly…

If you continue having an issue sing out.

![]()

Yes, the other setting that would cause that is diameter. Double check that.

Couple questions, what is your microsteps / 360 degrees, and what is your Diameter/ split/ overlap? Post some screenshots.

Make a narrow rectangle equal in height to your circumference and try it in line mode. see if you get a full wrap. I like to wrap a tumbler with black painters tape, get a nice crisp white line with not a lot of power for testing.

But bottom line, agree with Jack, if steps are correct and diameter is correct should work.

EDIT: I assume the rectangle or square comes out correctly on the flat/ no rotary.

On a flat surface it is exactly 20mm. It is set at 32 steps. The enable rotary is unchecked because I burned a flat image and didnt recheck it for the pic.

Sure you don’t have your circumference in the diameter field? 174mm is almost 7"

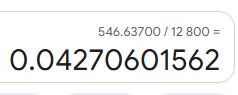

Also, 0.010 is a really small split. If I divide your circumference by 12800

That is the absolute smallest amount of surface movement (split) you can get, so you are asking your equipment to do something it can’t.

Thanks for pointing this out, learning the fiber laser and the settings. Ill change this tomorrow morning and let you know how it goes.

Try a split that is an even multiple of your minimum, somewhere between 1mm and 5mm on a tumbler, 0.1mm-0.9mm on something small like a ring. Personal preference but use an even multiple of circumference/steps. If everything else is dialed in, shouldn’t need to use overlap. I also make my line interval an even divisor of the split. So instead of split of 5mm and a LI of 0.0254, With your dimensions above I would use a split of 4.27mm (100X the minimum step) and LI of say 0.0213 or 0.0214 (evenly divides into the split)

Thanks for that info, i did enter my circumference and now it burns correctly. Ill mess with the split number tomorrow.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.