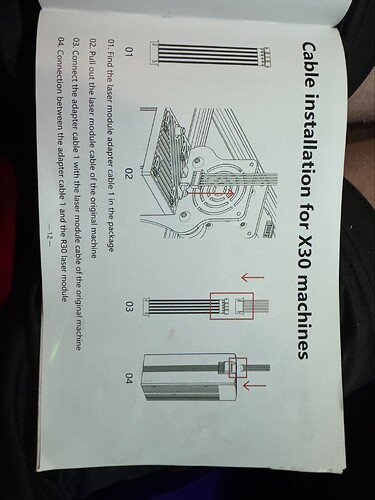

Hello, Brethren! I am a bit puzzled as to why my R30 Module will not fire. The laser that came with my X30 Pro works like a charm, but when swapped out it will not do a thing. On the manufactures youtube install video it does show my machine without the additional circuit board being used. Ive tried with an without and it will not fire. It will do everything besides fire the laser. Anyone have any experience with this???

Will really have little to do with software

Also IR beam is nearly invisible

Thinking how you could validate the signal.

Also is it a V1 or V2, they aer 12v modules arent they?

It is the V2 and yes it is 12v. And yea i figured LB had little to do with it, but wondering why using the same cords it just wont fire on one module and fine the other.

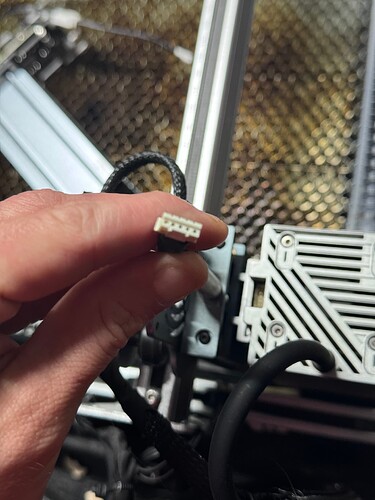

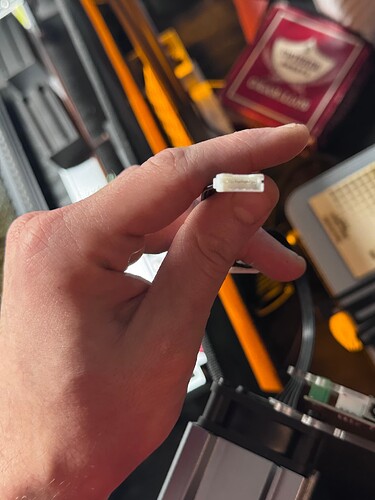

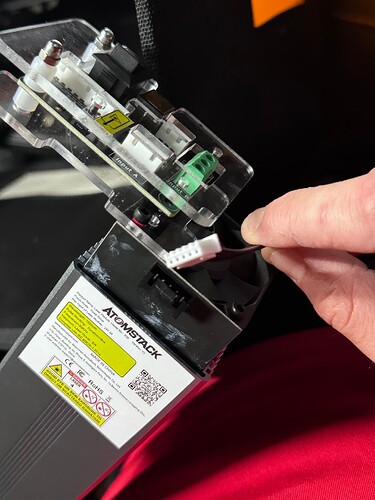

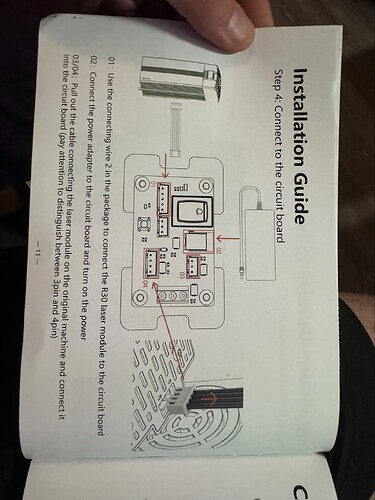

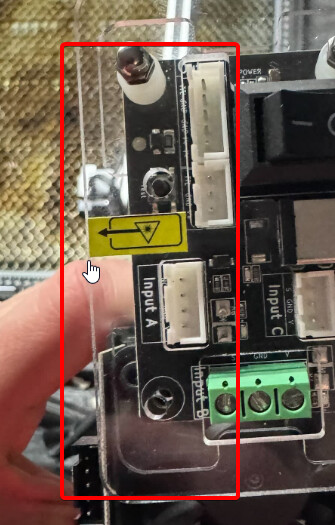

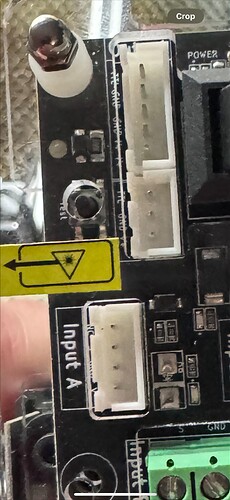

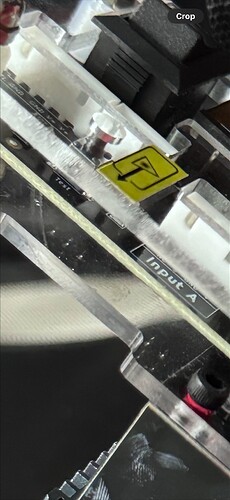

any chance you can post pics of both connectors and board?

The video dont show the connections labels

Uploading: IMG_1287.png…

Uploading: IMG_1288.png…

Nothing just red light on job and with button

my forum might be borked

Says images are stil uploading for 20 mins ![]()

So hypotetically, the module connected to the board directly, with the power adapter should fire when you touch the test button

Fan should trigger, and module should fire

As far as i know it does not have preheat so should fire right away

If it doesnt:

- i would get in touch with atomstack for procedure of testing

- any other machine you could try it with?

How do you know it isn’t lasing?

Focus is super critical, the shorter the lens the more critical the focus.

If it turns read on the interface board when you press fire… it’s probably lasing or thinks it is?

I’d suggest you ramp test it for proper focus…

What material are you lasing?

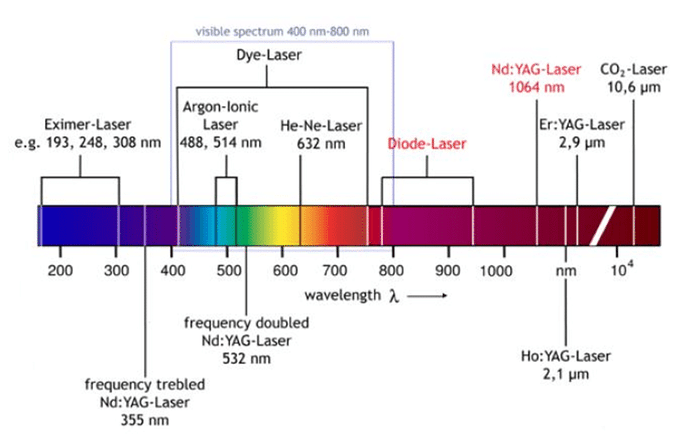

It is not visible… no doubt. An Nd:YAG laser is the same frequency as a fiber and is probably what’s in his laser module… Any wavelength below about 750nM isn’t visible. A co2 is about 100 times lower in frequency than a YAG, both in the IR frequency range.

This means you weren’t paitence enough to wait for it to complete uploading…

![]()

There isn’t the slightest mark on the 1/4in peakwood. Agreeing that it does assume it is lasing - since the blue laser indicator light turns on when I start a job.

As a newcomer, I’m not sure how to do focus test. Could you share some wisdom?

Yes, hence the

No other machine unfortunately. I emailed them, just waiting their standard 36-48 hour reply.

dang GLUCK

keep us posted on their diagnostic steps

Will be a nice learning stepping stone

I assume this is wood?

I’d expect no marking ability on wood … Wood is a natural product and isn’t damaged by using a 1064nm laser… This is likely your issue…

Use something made of metal or plastic like in the advertisement …

Hope you’re following safety precautions, such as eye protection while you are working on this ![]() … it’s likely lasing and you’re unaware …

… it’s likely lasing and you’re unaware …

Good luck

![]()

So I’ve since tried a metal aluminum tumbler, black acrylic, and a flat crystal surface. It made a very very, very light mark on the black acrylic, and nothing on anything else, this is at 100 power, and 1800 speed.

Mine is a fiber with a lot more power, but on my co2 I’m running pretty slow…

Is the 1800mm/m@100% a suggestion from atom stack?

Seems like 30mm/s is pretty quick… try a few below 10mm/s… However I know little about these modules.

Are you sure it’s focused? These go out of focus just a bit and they don’t appear to be working.

![]()

Im very new to the hobby. It was not a suggestion, more so me just apply more power and less speed in hopes to see something produced. How do you mean focused? as in the distance from the laser to the material?

Yes, this frequency to operate properly needs to be focused very close to it’s actual focal length… Unlike a co2 or standard visual light laser.

You can try a ramp test, but with this frequency you might try how we do it with the fiber…

Put a piece of metal in it and vary the head height, using sound of the laser/material to find the most loud area.

Most of the ramp tests are for ssl, but the idea is the same. It’s going to be more difficult with a low output type device.

Good luck

![]()