Dear All,

I have recently purchased a laser cutter working with Au3Tech software.

Is there any chance Lightburn could be made compatible with Au3Tech ?

If not, would any one know how to change the Au3tech controler to one which works with LightBurn ?

Thank You in advance formuour Kind help.

Sébastien

Is this software what is running in the controller or is it an application you use to control the laser?

Au3tech make controllers and software.

It comes as a bundle.

I don’t know what it is based on.

What have you tried so far? Not holding out much hope because machines like that often use proprietary communications software.

Can it accept SVG, DXF, or AI files? You can design in Lightburn and export one of these formats. You can also export PDF by using the Preview mode.

It accepts DXF.

The main problem is that it only offers line cutting.

There is no surface engraving option.

The interface is merely a copy of the metal cutting software.

If Lightburn can be used is based on the controller type.

If this is a closed system, then Lightburn, likely, won’t communicate with the control board…

Got a photo of the control board?

![]()

Test it! Lasers are only line cutters. Etching is just a bunch of lines really close at lower power.

Laser offer two methods of working

- Following a line

- Filling a surface with lines

The Au3Tech software doesn’t let you fill a surface.

There is no surface etching possibilities.

This is what it looks like.

The model is MCC3721NC-A

(Low Price MCC3721NC-A CNC Motion Controller Manufacturers, Suppliers, Factory - Made in China - Au3tech)

Can you use different speeds and powers on Au3Tech software?

Try this dxf (100x92mm) exported from Lightburn, it has 2 errors but only for testing. Use a setting with low power just to mark the material (e.g. cardboard).

_Fill_forum_test.dxf (1.2 MB)

Try this one instead is not so dense and will take less time.

not_dense_Fill_forum_test.dxf (34.9 KB)

Thank You for your message and file.

I am away from the machine, now. I may go back to it tomorrow. If not, on Monday morning.

But there are layers and cutting parameters in Au3Tech. In the CO2 software, you can set speed and power, for each layer.

I have tried your files.

It worked fine.

This is a great workaround.

Thank You for finding it out.

Unfortunately, I don’t seem able to export files from Lightburn, to be used in SC800.

Only the outline exports.

Would You please explain how You did this ?

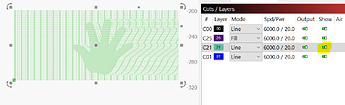

Make sure everything is selected and all layers are set to output.

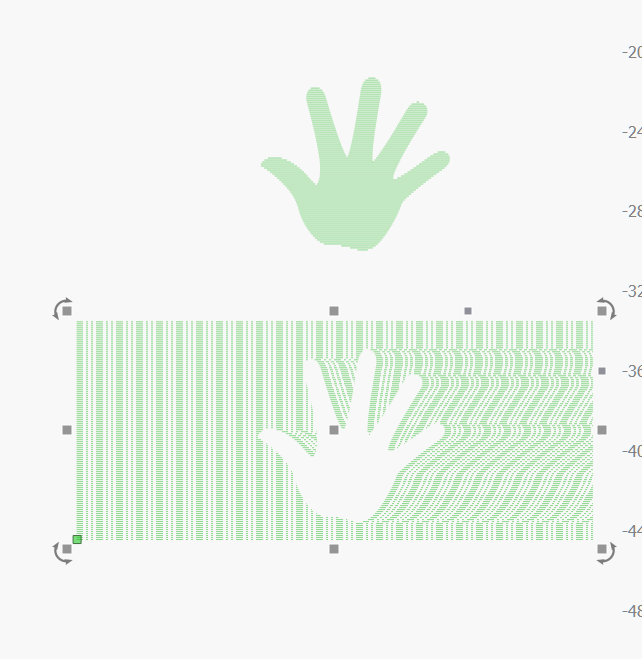

Basically fill are just parallel lines, my example is not the correct way but a workaround.

You should know your laser spot size, to set a distance between the lines or defocus a bit and increase the distance winning less time engraving.

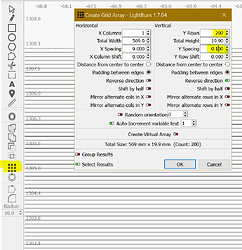

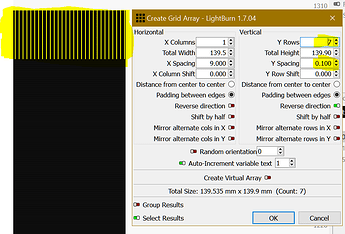

- Create an horizontal line bigger than your shape

- With the Array tool create Y (max 200) parallel lines at e.g. 0.1 mm distance between them

If you need more height select all the above lines and repeat

- Group the lines.

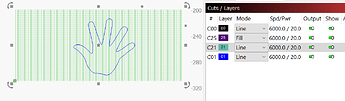

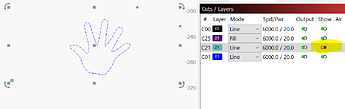

- Place the closed shape that you want to fill over the multiline

- Select the lines

- Hide lines (Cut/Layer toggle show) then select the shape

- Click show toggle.

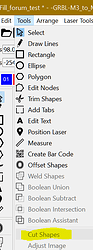

- Goto Menu > Tools > Cuth Shapes. . . (selection order matters)

- Move the cut aside to show your “filled” shape

- Select your shape then Export.

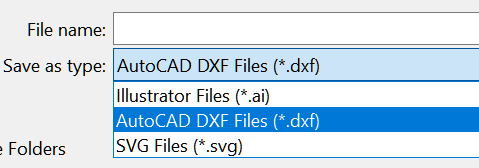

- Export as DXF and run on your laser.

.

Pay attention that this is a bit CPU hungry, do one shape each time then join all in a new project file.

Do some tests with distance between the lines (it´s your interval test).

_Fill_forum_test1.lbrn2 (121.8 KB)

_Fill_forum_test.lbrn2 (4.8 MB)

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.