… if you do not know what to do in the wait for your laser to come - here is the ultimate reference in laser technology

https://www.youtube.com/user/SarbarMultimedia/featured

Russ is the guru of the laser geeks. There is something about this man, I enjoy his videos where we are part of his learning process and witnessing extremely accurate tests and trials. He has also built a number of auxiliary tools for, for example, fine tuning of the laser beam.

For long winter nights, coronary crises, and endless long waiting for the arrival of one’s new laser … or just to learn a lot and be happy and impressed at the same time - Russ is the man!

(find the videos from about 4 years ago, they deal with his start with his first laser, if I remember correctly)

Some videos of Russ are very long, my wife watches “Midsomer Murders”, I watch "SarbarMultimedia # …

Hi Mark,

Have you got your new machine?

Hi Bernd!

Yes deliverd yesterday.

I will unpack this on Weekend.

But first I have to make room in the office and cut the table and do some other things

but I can’t wait, even if I’m a little afraid of doing something wrong!

Hi Mark, Congratulations

OMG - you’re not ready to press the start button - it’s awful.

I wouldn’t be able to wait a second. I look forward every time as a little child to Christmas when I get a new toy (tool).

Just be careful, make some documentation for yourself and enjoy the process itself, that’s a big part of it all and the benefit we have as hobbyists as opposed to the professionals who needed to make money.

Hi all!

Here a little Update…

I got the Laser a VEVOR 60W…

unfortunately I have some problems

somehow I can’t get a clean laser beam out of the tube. this is probably broken.

but also 3-4 other problems which I can or have to fix myself

like the safety switch for the open lid, the damper from the lid hangs too far down there the laser head moves against it …

Hi Mark,

You come with both good and bad news.

first, how does the laser react when testing it, is the total dark, no purple-blue-yellow light in the glass tube ?, what is your mA setting ?,

is the laser tube completely filling up with water - without air bubbles?

could you make a few pictures of the machine, please

The other “small things” are usually in this price range and easy to fix.

Hi Bernd!

I can see a purple-blue light in the tube, but u gut no fine beam (point) i always get a “4-point” point, if i can call that so …

how much mA i dont know, i dont have one installed at this time …

but i use max 50%…

because the tube i must check i again, but i mean there where no air bubbles

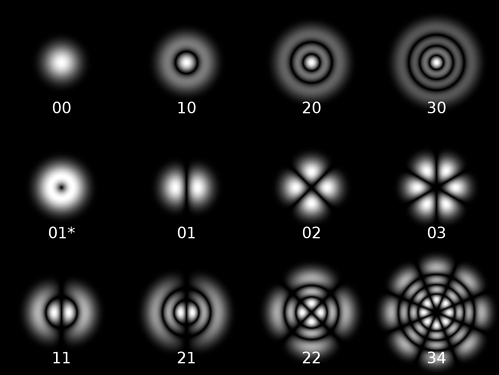

Hmm, a 4-point output pattern is not good. If what you’re describing looks like mode 02 in the image below, your tube is junk.

yes it looks exactly in the direction!

I have already written to the seller, but you know how it is with weekends and holidays: '(

I have never seen or heard of this before, but it is bad in all circumstances.

Now it will prove how good the supplier is. The time I got my machine with a broken tube, I had to discuss a little back and forth, but finally after I agreed not to mention the trade negatively on ebay, a new laser tube was sent.

I want you to get a proper solution of the problem too.

Does everything else work as it should?

thanks for the kind words.

i hope i get a new one without long discussions …

But then swapping them myself also poses a very big task because everything is new to me.

Otherwise, there were a lot of metal chips in the housing when I delivered it, which I had to remove first.

Also, in front of the laser head, always against the left damper that opened the lid, so I had to drill a new hole and set the damper a little higher.

In addition, the Open Cover Protection switch did not work.

I spent almost the whole day today and found that the function in the firmware was simply forgotten to be activated.

Have now done that and that’s also done.

The grazing cable chain remains on the built-in lamp, so drill new, higher holes for the lamp and attach the new one.

Otherwise “only” the housing is scratched and the bed on the left maybe 1-1.5mm higher. But unfortunately I will not be able to fix that. To do this, I would have to remove the entire bed and shorten the iron angles or generally add new ones. I think I’ll leave that with the bed for now, because I want to learn to laser and understand everything first.

For that I need a working tube first.

Greetings from Austria

What you describe sounds familiar and unfortunately quite normal for our machines from the People’s Republic.

But, it is also part of the learning process and there will be some more of it.

… you write firmware when you mention the security switch, don’t you mean the controller software?

The difference in the height of the bait - you should be able to loosen the belt from the height adjustment and screw the bolts individually until they fit the height.Then you put the belt back on.

If your machine is that far out of whack, it may be worth trying to return it. Some tweaking is to be expected from the imports, but it should at least be somewhat workable when you get it. Consider looking into the dispute process with however you paid for it.

As far as the tube itself, it’s just extremely fragile. “Be careful” and you should be OK. Maybe a couple of wires to solder, although they should be connectorized somehow. Keep note of how everything is put together (take pictures) and you should be able to put it back.

NEVER solder the wires to the tube. You will damage the tube in doing so, the heat will crack the seal around the post. The correct way is to wrap the wire around the post, then insulate it with silicon caulking.

… switching a laser tube is not rocket science, there are some nice videos on the web and if you follow the advice of Rick and Anthony, you will succeed.

Hi Guys!

Thanks for your advice!

by “firmware” I meant Ruida the controller itself!

The function was simply not activated there

this is just a click in RDworks to activate this in the vendor settings.

and I spent a whole day troubleshooting …

i think the other things like the lamp and the damper relocate are small things and probably normal for such china goods.

I definitely don’t want to send it back because the column was 185kg and I would have to pay for the transport!

let’s see when the seller reports and if I get a new tube!

best regards

How much does the machine itself weigh, approx. and is it possible to separate the chassis / leg part from the machine part?

I’ll keep my fingers crossed for you

Have you heard any news from your supplier?

yes, made some videos but it looks not good for me…

The seller want change the tube…

i have now made a another video and photos and wait the seller responds