Hey, I’ve been working with a 150W CO2 laser for about 1.5 weeks now and I’ve received a project to cut on 3/4" acrylic. I’ve messed around with passes and power and can’t seem to find the best way to cut this cleanly and all the way through every time. I recently found out my work area wasn’t leveled as well so I assume that can also be an issue with half of the letters cutting all the way through and half not. I would still like to see if anyone has experience cutting through 3/4" or even 1/2" acrylic. Thanks!

It could also be my speed which I haven’t played around with yet. I just have a weird feeling I could be doing this in less than 8 cuts…

I have cut 16 mm acrylic with my K40. But the speed has been very low, in fact just fast enough that the acrylic does not weld together again. I used 2 passes for it. 8mm I cut with 2 times 300 mm / min. So you should be able to easily cut it with your machine, of course focus is important, I like to focus in the middle of the material thickness.

For 3/4 I imagine you will need a cutting lens setup as opposed to engraving. You don’t say what you currently have fitted. Generally 50mm for engraving and 100mm for cutting seems to be go to lenses. With my 50W 50mm setup I can just about cut 8mm acrylic at 200mm/min at 100% power (limited to 18mA in LB).

Cheers

David

What do you mean by focus in the middle of the material thickness? is that using the z-offset focus in the middle of what i’m cutting?

Not sure if I’m looking at the right number but I believe it has a diameter of 20mm and length of 50.8mm

sorry if I was not clear, for materials over 3mm thick, my focal point is in the middle of the material - and not at the top of the material.

That is the lens I use and it has a very short focal length. A good compromise for engraving detail and cutting, but unless you have a lot of power available I would be surprised if you could cut 3/4 acrylic. The compromise really is the size of the beam when focused. The 100mm lens has a bigger dia so isn’t as good for very fine engraving, but the focal length is much longer so it stays in focus through thicker material. You can do as Bernd suggests and move the nozzle lower or raise the bed to put the focus point part way through the material, but I haven’t really noticed much improvement doing that with my 50mm setup. I guess the focal length is so short that then the top cut is being done with an out of focus beam and doesn’t cut well.

Cheers

David

for example 6 mm plywood - my focus point is +3 mm = 53.8mm, which is a reasonable difference for my standard K40 laser with 12mm lens, 2 "/ 50.8mm focal point.

I’m sorry, I appreciate both of your help. I’m also looking at the manual which is not helping at all in this case. There’s no info on changing these settings. I’m not sure if this makes a different but my laser has a autofocus feature where the work bed rises to a sensor and adjusts depending on how thick my material is. If I move the laser up and down changing the focal length the auto focus rod moves with it. I could manually move the auto focus rod up and down changing the overall focal length. I guess the solution to increasing my focal point would be to move that auto focus rod down to increase the focal length by 3/8"…

Can’t you simply turn the auto focus off and focus by hand?

…yes, try temporarily turning off autofocus as Hank says and do a test with different focus settings manually. Nor will it surprise me if you find that your pre-set focus does not fit correctly.

The 50mm lens probably has a useful focal depth of no more than 10mm (half the thickness of your material). As others are suggesting, at a minimum you’ll need to do multiple passes with the focal point about half way into the depth of cut (5mm for the first pass, 15 for the second pass). Alternative is to use a 100 lens as others suggested which should have enough depth of focus for this job. Air assist is a must, but don’t turn it on too strong.

UPDATE: a longer lens will also give you a more vertical edge. 50mm lens will be significantly beveled.

Be careful with the air, with acrylic you only need to keep your lens clean with air. If you blow air into the groove you are cutting, you easily cool too much. The acrylic vapors also have difficulty getting out of the “hole” if you blow air in the opposite direction (at several passes / bottom holes / cutting)

Out of curiosity are you using a BOSS laser? Your set up sounds just like mine and I’m using a BOSS laser.

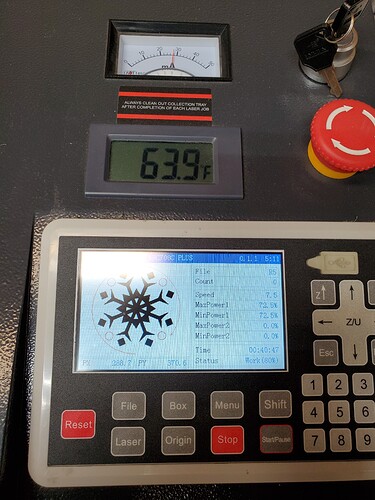

My laser is 150 watt with the auto focus and I cut 1/2" acrylic all the time and my settings are

Speed 7.5 mm/sec

power max 90%

power min 72.5%

air pressure 15 PSI

I use these settings on 1/4" 3/8" and 1/2" for cutting and my cuts are very clean and smooth. I make a lot of signs that are edge lit and the edge quality is great at these settings for me.

I forgot to add that I do not use auto focus. I have a 3mm thick piece of plywood that I use to focus my laser

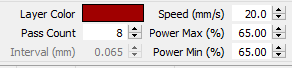

I have a Laguna laser cutter. I was struggling cutting 3/4" acrylic for a sign but I also didn’t lower my speeds much which I’m learning makes a huge difference. I haven’t had much time to test cuts before we started cutting letters for signs but now I’m trying to find the best settings for cutting in as few passes as possible for time sake and cleanliness for the sides. I usually like sticking at 65% max power to reduce wear on the machine; any higher usually sends my mA in a zone they told us not to go often. we mostly cut 1/4" and 3/8" so I’ll try to lower my speeds and get it cut in 1 pass. I’m learning I should probably make some focus blocks instead of using the autofocus too, it seems many people do it that way, I just don’t know enough about how far I should set the laser for different thicknesses. Still very much new to this.

I didn’t think to add that but yes at those settings it is only making a single pass. I’ve never tried multiple passes on anything

I know I am replying weeks later but I’m starting to learn more about the power of the laser I am using so when you say you use Max 90% Min 72%, is that 90% of 80 Max power? I realized my laser tube is set to max out at 80. Also, if so, is it healthy for the laser to run at 90%, I try to keep the ammeter at around 28 mA

Jason

I apologize I’m not sure why I put 90%? I must have either typo or had something else on my mind?

I just double checked because I’m doing some 1/4" acrylic as I speak.

The power is 72.5% for both min and max. I am also running 28 mA on my machine when it is cutting.

My settings are

Speed 7.5 mm/sec

Power72.5%

air pressure 15 PSI

28 mA

Sorry for any confusion

Michael