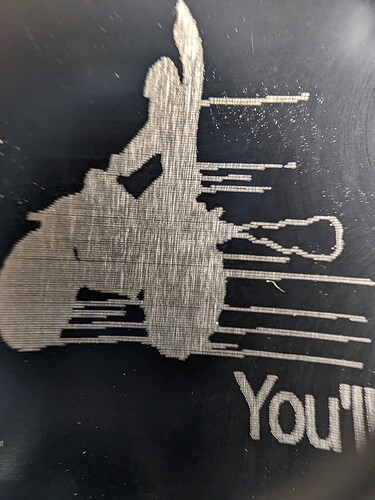

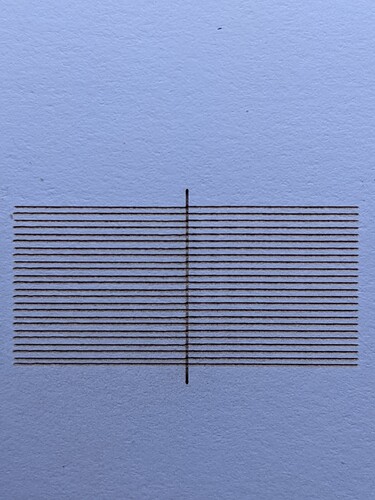

When using my monport laser on bi directional engraving, I have oddly spaced horizontal lines. When I turn off bi directional, I don’t get weird gaps. This happens at every speed and every line interval. Acceleration values do nothing but slow the machine. I truly believe this is a hardware issue

It’s a repeating pattern…wide, skinny, wide, skinny… almost like one of the pulleys is not round or has something in it… I’d check for any mechanical drag without power and see if you can ‘feel’ anything.

I’m having difficulties what is common between bi-directional and single direction that could cause this to occur, that could be controller related.

It appears to occur with the Y axes.

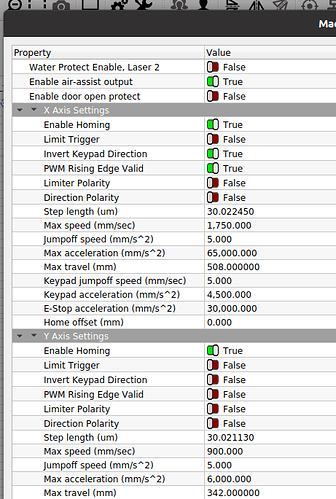

Before modifying anything, make a backup of the supplied configuration via “Edit → Machine settings” and ‘save’ it. I have multiple configuration files…

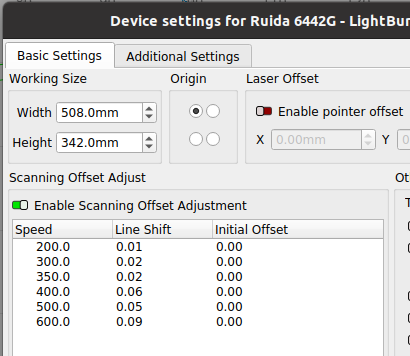

Here are some of my setup… The max speeds and acceleration values probably won’t work, but many of the others should be in the ‘ballpark’

Check the pwm falling and rising parameters. I can’t see how it could be related to this but it shouldn’t hurt anything to change it and test. Assuming no other options. This is just a shot in the dark…

Good luck

![]()

My man 65,000 acceleration? Are you on servos, what laser is that? That’s fantastic

This laser is using inner roller type guide bearings, there doesn’t appear to be any drag on either x or y.

I’ve tested the PWM but I will do a more in depth test later today.

I’ve adjusted jump off, start speed, and acceleration speed with zero positive effects.

Both x and y are on reduction gears, I wonder if the belting is overly tight on y and is causing the intermittent lose in steps. It is incredibly consistent which leads me to believe it’s controller, driver, motor, or maybe lightburn. I have difficulty thinking it’s lightburn because my other laser can run the exact program without Ill effect, but who knows.

I was going to look into how much voltage is being applied to the motors but I don’t have a clue how to go about that. I am planning on investigating power being supplied to the motors later today as well.

I appreciate your reply

If it were backlash chances are it would eventually even out, wouldn’t you think?

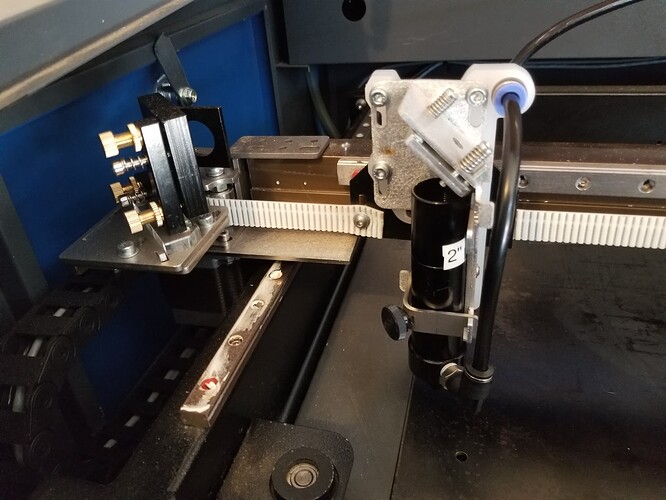

Ahhh I see you got Russ’ head. I bought it too, haven’t installed it yet. Would you mind sending pictures of the left and right ends of you x axis? I’d love to see how you adapted the belt to the stepper motor and your mirror mount looks interesting

Not if that means what I think… but it usually just shifts it for that cycle.

What makes yours odd is that it’s pattern is easily seen.

I don’t know how you could program this via software. It seems the only thing left is a mechanical issue.

I think you can see most of what you asked about here. There is no change on the right end…

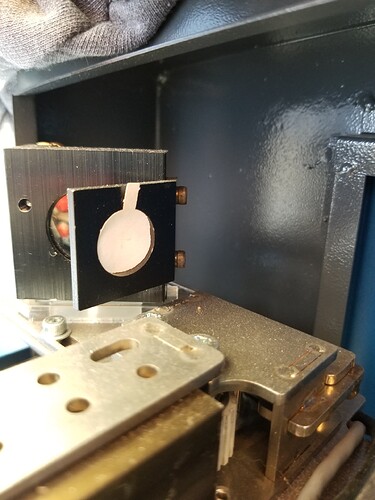

This is the view of m2 from ‘inside’… the beam goes around from m1 on the right and makes a left to m3. You can see the case slopes to the front away from you.

Head with 2" lens and long nozzle. Cuts through 3mm basswood with 30psi very cleanly, no residue. Focus is about 5mm from the tip. Lens is up in the lens tube.

Lens is configured this way…

![]()

Ahhh I see, your stepper is on the left hand side with your mirror. Mine is on the right so I am unable to make his mirror mount work on mine. He did, however, give me a prototype to fit to the right hand side. I was hoping this new laser would be good to go and I could tear into the other one and make it a speed demon like yours. In due time I suppose.

So maybe I don’t fully understand ‘Backlash’. I am under the impression that backlash can be predicted and therefore compensated within the vendor settings. I will have to further investigate backlash.

The absolute puzzling thing for me which I cant even begin to comprehend is this…

There is a straight line that separates two sets of squares (I forget the dimensions). The left side is scanned bi-directionally at a .6 Line interval. The right side of lines are scanned with that setting turned off. So the laser head only engraves left to right. If it were some sort of mechanical issue you would think it would also show on the right hand side, right? I mean the only difference between the two is that the laser doesn’t fire when it scans right to left.

I unfortunately didn’t have the time this evening to tear the machine down and give it a thorough cleaning. I’ll give that a shot tomorrow. Also, I’ll mess around with the PWM settings as well.

I appreciate you throwing some ideas out there and thank you for the pictures

You can see the backlash on the left where the ends of the lines don’t line up.

When there is backlash it occurs when there is a directional change as evident by the left side of your picture.

Single direction scan won’t show it because the backlash has been taken up by the time the line is drawn.

Adjustable in “Edit → Device Settings”

The adjust works only on the selected speed. I will get offset at 200mm/s but not at 201mm/s, keep it in mind.

A bit delusional… ![]() the speed is fun to play with, but practically it’s of little real use. The benefit comes with the ability to change the head direction more quickly.

the speed is fun to play with, but practically it’s of little real use. The benefit comes with the ability to change the head direction more quickly.

Simple facts are that the lps on these are usually ‘specified’ to have of a response time of <=1mS to reach 90% of it’s voltage.

If it is worst case response or 1mS that means you can put down (in 1 second) a 1000 dots or 1s/1000.

If you pick 300mm/s at 300dpi. 300mm/s is equal to 11.8 inches/s. For 300dpi, you need to produce 300dots x 11.8 inches each second or 3543 dots.

The lps can produce 1s/1000 dots and you need 1s/3543 dots. That’s three times faster than the supply can respond. ![]()

You can also get ‘reject’ lps from the unscrupulous vendors that failed this response time test…

Keep this stuff in mine… ![]()

Russ has a great video on this, but I can’t seem to locate it… ![]()

Good luck

![]()

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.