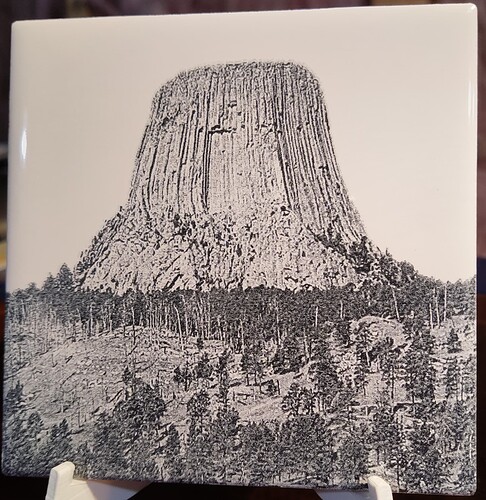

That’s nice Mike. I think the acrylic paint (PVA in my case) is the key to holding, when dry, the Titanium in place while etching. Most importantly is getting it all mixed evenly. Nice solid blacks and fine detail proves the process is a success.

Same mix.

Almost ready to make another batch.

I last messed with Ron’s method a couple of months ago… but could never get even or consistent coatings. However BikeMike’s recipe sounds like it might be more workable than what I last tried… using white acrylic craft paint vs PVA glue. But I have a silly question…

When you said, “mix in 2 1/4 teaspoons (us) titanium dioxide”… is that

-

specifying TWO 1/4 teaspoons, or

-

2-1/4 teaspoons (NINE 1/4 teaspoons)

of TiO2?

Thanks.

– David

2 teaspoons, then 1/4 teaspoon.

Add enough water to thin it so it will flow out smooth in 15 min. or so, but not so much it just runs of the tile.

When you think you have it mixed good enough, do it again. It has to be mixed very well before each use.

Thank you!

Here is where I am at with this.

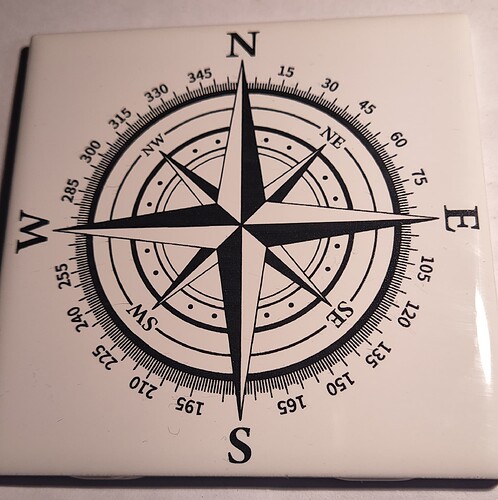

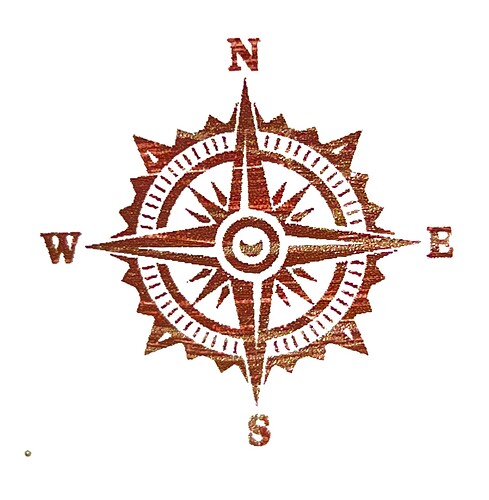

The first is the compass I did in fill mode.

The second is in image mode.

They both came out fantastic using my method.

It does take some testing, so don’t be discouraged if it does not work the first time.

You will need to do…

Line interval test.

power and speed test using fill mode.

And a gradient test for power and speed.

They should get you in the ball park.

If you try this, please post pic’s of what you have done.

Hi!

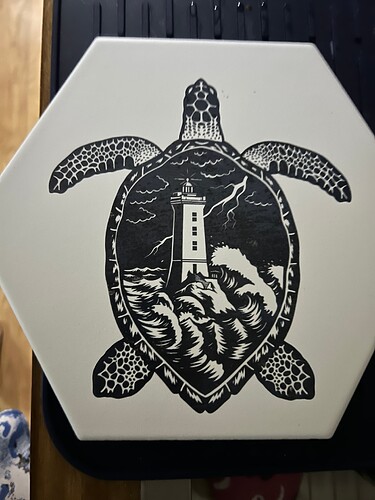

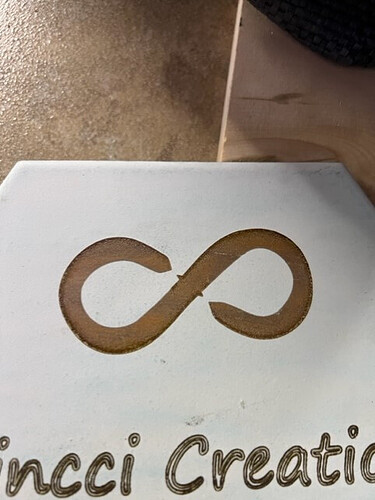

Apologies for intruding! My name is Robin and I paint (not walls ![]() } so I am familiar with TD I’ve been following this discussion as tiles are all I have been able to do (my laser dislikes me lol). If the pics come through I would appreciate any advice! The first two should be with TD/ethanol. The next one is something I’ve been playing with.

} so I am familiar with TD I’ve been following this discussion as tiles are all I have been able to do (my laser dislikes me lol). If the pics come through I would appreciate any advice! The first two should be with TD/ethanol. The next one is something I’ve been playing with.

Not an even spray.

The laser jumped… I think

An idea. The scratches were caused by seeing if the color would scrub off.

Oh! I forgot! I have a confused Longer Ray5 10 Watt!

Not exactly sure what you asking advice on.

What was it you used for the redish one?

My apologies and thank you for responding!

If you zoom in you can see there are parts that are darker than the rest. I am wondering if it is due to this being an ink sketch I scanned in, uneven spraying, etc, (the top one).

It was the second tile I had done and it’s matte. Would that make a difference?

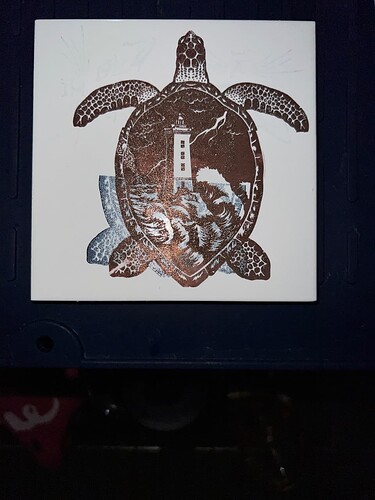

The reddish one is actually copper but it’s Mica I am still working out the kinks in how much I can push it before it clogs the sprayer.

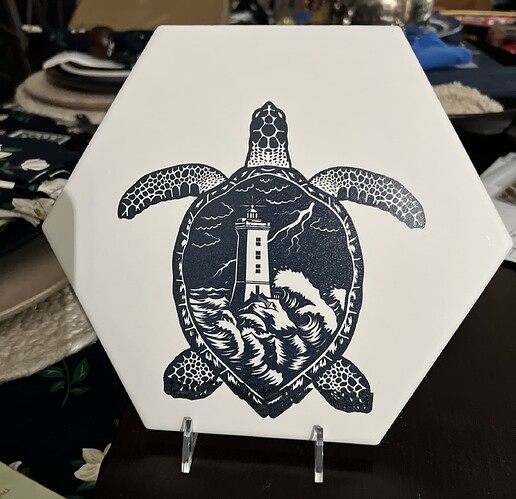

Hi Robin, Your tiles look similar in quality to my best ones. I have found that if the image looks light it is usually due to a too thin coating of Titanium Oxide.

Can you elaborate on the copper colour mica addition?

Thank you! Yes I can. Mica is a very fine powder dye. The copper color resulted from having put the sprayer from the TD mixture in the cup with the antique gold. I’ll look for the tiles that I have been testing it on.

Mixing any color with the TD will still result in a black scan if you use too little but it will have a tint to it. Accidently mixing a little with antique gold mica results in copper.

Brand matters too. It dries fast so I have one shot if I have a hope of an even cover. It seems to prefer isopropyl alcohol to ethanol as well.

Give me a few moments, a prayer my laser behaves, and I will upload a new engraving.

Thanks Robin, I will do some experimenting as I have a box full of Chinese mica powder colours to try. I had no luck at all doing the normal engraving and adding the mica powder to parts of the i age for a second laser pass. It either blows away or burns.

It’s not an exact science though I should try harder to measure. I do know if you want it to really stay it has to be thick and not lumpy or it jumps

The spoon and mica

This one was late last summer:

This was when my laser just stopped. Guess it was tired lol but I was working with blue mixed with TD

I definitely feel the pain on no luck! Good luck!

Add regular rubbing alcohol and turn off the air assist. That should help. If you are using Let’s Resin brand it doesn’t engrave well. It’s too light in weight

I have tried ethanol with my TD and distilled water mix making the airbrushed coating application faster, but the fumes in my small workshop get a bit much to bare. Preheating the tiles on my vertical hotplate works fast enough with a simple water and TD mixture. Hopefully the mica addition won’t clog my nozzle faster than the TD does.

If this works, the next challenge will be obtaining near perfect positioning between multi stage / multi colour coatings and engravings.

Literary Brand Antique Gold Mica Powder dye that I had put the end of the sprayer from the bottle of titanium dioxide. A little of the TD will change the color. A lot of it will burn black with a tint to it.

This one hasn’t been scrubbed and I am running one on a clean tile but the focus is on the amount of

Mica left when it’s only combined with alcohol.

Now back to your expert advice. Mineral water… I have never heard of this but I am going to try it.

I also noted you mentioned warming the tile. I have a resin heating pad and a candle warmer but would like to know more about how this part works.

Your tiles are superb! Mine are hit and miss.