I have a HP2436 and Lightburn. Is there any difference between regular Lightburn and the Boss version?

The Boss Logo on the splash screen and a link to their tech support page / phone number in the help section. Otherwise they’re the same.

Thanks, a materials library for starting settings would be a great thing. I know I have heard many times that no two lasers are the same, but I am talking about starting settings. Other laser manufacturers do it. If you have any influence you should pass along the suggestion. Even if it was just the settings from the settings page they have, it would save us from having to key or look them all up.

Shouldn’t you take that up with the salesman that sold you the machine?

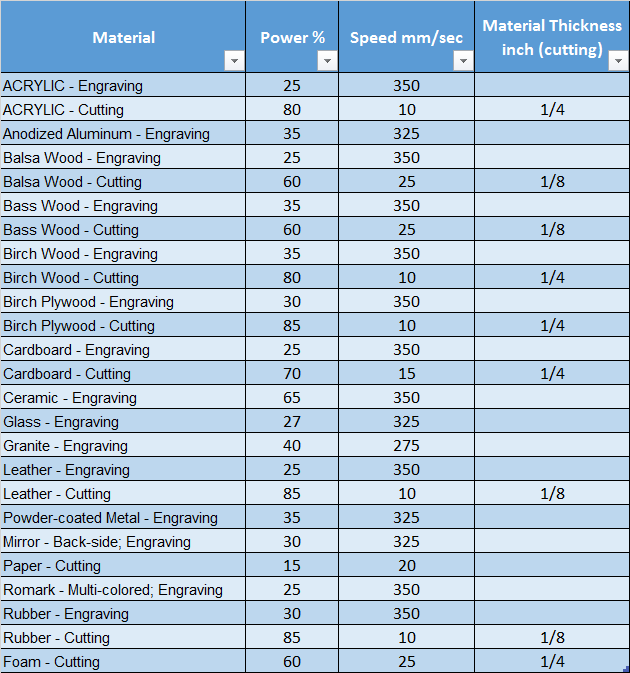

Thank you for this suggestion. We have gotten this request before, but with our size, it is just not practical. We would get nothing else done.  You could also recommend this to Boss as they would be the appropriate publisher of such libraries. They have all the data from their testing. https://www.bosslaser.com/laser-settings

You could also recommend this to Boss as they would be the appropriate publisher of such libraries. They have all the data from their testing. https://www.bosslaser.com/laser-settings

It’s actually something I’ve considered - I would like to try to make libraries for 40w, 60w, 80w, 100w, and possibly 5w (diode), but it’s all time and priorities. LightBurn is one developer and two support staff, and a part time dev who’ll be joining full time next month. With twice the developers we should really start cooking.

Ideally if they just made the settings page available in a file format that could be imported into lightburn. With the collapsing html tables they have it is a pain to grab the data.

I’d rather see developer effort spent on on features - I can pretty easily create my own material libraries but adding something like fiducials (sp?) to the feature set is way beyond me and most other users.

LIke this

ACRYLIC - Engraving

[ WATTS POWER % SPEED(mm/s) INTERVAL / SCAN GAP (mm) THICKNESS

0 65W 25 350 0.065 ANY

1 100W 20 350 0.065 ANY

2 150W 15 350 0.065 ANY]

ACRYLIC - Cutting

[ WATTS POWER % SPEED(mm/s) INTERVAL / SCAN GAP (mm) THICKNESS

0 65W 80 10 NaN 1/4"

1 100W 75 15 NaN 1/4"

2 150W 65 20 NaN 1/4"]

Anodized Aluminum - Engraving

[ WATTS POWER % SPEED(mm/s) INTERVAL / SCAN GAP (mm) THICKNESS

0 65W 35 325 0.065 ANY

1 100W 20 325 0.065 ANY

2 150W 15 325 0.065 ANY]

Balsa Wood - Engraving

[ WATTS POWER % SPEED(mm/s) INTERVAL / SCAN GAP (mm) THICKNESS

0 65W 25 350 0.065 Any

1 100W 20 350 0.065 Any

2 150W 15 350 0.065 Any]

Balsa Wood - Cutting

[ WATTS POWER % SPEED(mm/s) INTERVAL / SCAN GAP (mm) THICKNESS

0 65W 60 25 NaN 1/8"

1 100W 55 25 NaN 1/8"

2 150W 40 25 NaN 1/8"]

Bass Wood - Engraving

[ WATTS POWER % SPEED(mm/s) INTERVAL / SCAN GAP (mm) THICKNESS

0 65W 35 350 0.065 Any

1 100W 25 350 0.065 Any

2 150W 20 350 0.065 Any]

Bass Wood - Cutting

[ WATTS POWER % SPEED(mm/s) INTERVAL / SCAN GAP (mm) THICKNESS

0 65W 60 25 NaN 1/8"

1 100W 55 25 NaN 1/8"

2 150W 40 25 NaN 1/8"]

Birch Wood - Engraving

[ WATTS POWER % SPEED(mm/s) INTERVAL / SCAN GAP (mm) THICKNESS

0 65W 35 350 0.065 Any

1 100W 25 350 0.065 Any

2 150W 20 350 0.065 Any]

Birch Wood - Cutting

[ WATTS POWER % SPEED(mm/s) INTERVAL / SCAN GAP (mm) THICKNESS

0 65W 80 10 NaN 1/4"

1 100W 70 15 NaN 1/4"

2 150W 65 20 NaN 1/4"]

Birch Plywood - Engraving

[ WATTS POWER % SPEED(mm/s) INTERVAL / SCAN GAP (mm) THICKNESS

0 65W 30 350 0.065 Any

1 100W 25 350 0.065 Any

2 150W 20 350 0.065 Any]

Birch Plywood - Cutting

[ WATTS POWER % SPEED(mm/s) INTERVAL / SCAN GAP (mm) THICKNESS

0 65W 85 10 NaN 1/4"

1 100W 75 15 NaN 1/4"

2 150W 70 20 NaN 1/4"]

Cardboard - Engraving

[ WATTS POWER % SPEED(mm/s) INTERVAL / SCAN GAP (mm) THICKNESS

0 65W 25 350 0.065 Any

1 100W 20 350 0.065 Any

2 150W 15 350 0.065 Any]

Cardboard - Cutting

[ WATTS POWER % SPEED(mm/s) INTERVAL / SCAN GAP (mm) THICKNESS

0 65W 70 15 NaN 1/4"

1 100W 60 15 NaN 1/4"

2 150W 50 15 NaN 1/4"]

Ceramic - Engraving

[ WATTS POWER % SPEED(mm/s) INTERVAL / SCAN GAP (mm) THICKNESS

0 65W 65 350 0.065 Any

1 100W 40 350 0.065 Any

2 150W 27 350 0.065 Any]

Glass - Engraving

[ WATTS POWER % SPEED(mm/s) INTERVAL / SCAN GAP (mm) THICKNESS

0 65W 27 325 0.065 Any

1 100W 25 325 0.065 Any

2 150W 20 325 0.065 Any]

Granite - Engraving

[ WATTS POWER % SPEED(mm/s) INTERVAL / SCAN GAP (mm) THICKNESS

0 65W 40 275 0.065 Any

1 100W 25 275 0.065 Any

2 150W 18 275 0.065 Any]

Leather - Engraving

[ WATTS POWER % SPEED(mm/s) INTERVAL / SCAN GAP (mm) THICKNESS

0 65W 25 350 0.065 Any

1 100W 18 350 0.065 Any

2 150W 15 350 0.065 Any]

Leather - Cutting

[ WATTS POWER % SPEED(mm/s) INTERVAL / SCAN GAP (mm) THICKNESS

0 65W 85 10 NaN 1/8"

1 100W 75 12 NaN 1/8"

2 150W 70 15 NaN 1/8"]

Powder-coated Metal - Engraving

[ WATTS POWER % SPEED(mm/s) INTERVAL / SCAN GAP (mm) THICKNESS

0 65W 35 325 0.065 Any

1 100W 20 325 0.065 Any

2 150W 15 325 0.065 Any]

Mirror - Back-side; Engraving

[ WATTS POWER % SPEED(mm/s) INTERVAL / SCAN GAP (mm) THICKNESS

0 65W 30 325 0.065 Any

1 100W 20 325 0.065 Any

2 150W 15 325 0.065 Any]

Paper - Cutting

[ WATTS POWER % SPEED(mm/s) INTERVAL / SCAN GAP (mm) THICKNESS

0 65W 15 20 NaN 1/100"

1 100W 15 25 NaN 1/100"

2 150W 15 30 NaN 1/100"]

Romark - Multi-colored; Engraving

[ WATTS POWER % SPEED(mm/s) INTERVAL / SCAN GAP (mm) THICKNESS

0 65W 25 350 0.065 Any

1 100W 20 350 0.065 Any

2 150W 15 350 0.065 Any]

Rubber - Engraving

[ WATTS POWER % SPEED(mm/s) INTERVAL / SCAN GAP (mm) THICKNESS

0 65W 30 350 0.065 Any

1 100W 20 350 0.065 Any

2 150W 15 350 0.065 Any]

Rubber - Cutting

[ WATTS POWER % SPEED(mm/s) INTERVAL / SCAN GAP (mm) THICKNESS

0 65W 85 10 NaN 1/8"

1 100W 75 12 NaN 1/8"

2 150W 70 15 NaN 1/8"]

Foam - Cutting

[ WATTS POWER % SPEED(mm/s) INTERVAL / SCAN GAP (mm) THICKNESS

0 65W 60 25 NaN 1/4"

1 100W 55 25 NaN 1/4"

2 150W 40 25 NaN 1/4"]

Yup, bravo… Perfect…

6 posts were split to a new topic: Trocen origin setting for camera use?

This seems like a good crowd sourced initiative.

A good subset of your users have settings they use regularly for standard materials. This could be done by the crowd:

- if entered their powers and speeds for materials,

- if any out-of-wack fringe settings were trimmed,

- if speed-to-power trade-offs could be established

then you could publish a middle ground number for each material type.

Granted, these would all be starting point or suggested settings.

I tell all my students to always begin with a test cut.

Starting with the numbers above would be helpful.

Everyone will still need to fine tune theirs settings.

No I was not sure what the other setting would do. Do I need to restart Lightburn each time I change a setting?

No. The only setting I can think of that requires a one-time restart is when a CGode user wants to turn on the ‘Enable laser fire button’.

Are you asking about a particular setting?

I agree.

My plywood, my MDF, my timber, my acrylic is not the same as someone else’s.

My laser settings are different - even between machines.

I build my library as I test. It’s not hard.

What make/model of ‘65 watt laser’?

I’m sure they are all different. Just as your machine’s implementation is different, depending on power supply, steppers, controller, etc.

But, good for a starting point.

These are general settings for a Boss 65 watt tube, I don’t think there would be a lot of difference between 65 watt tubes for these general starting point settings.

Thanks Allen,

I’ll give this as shot on my 65watt with mirrored acrylic. I have to do a few jobs and wasn’t sure where to start. Thanks for the starting point.