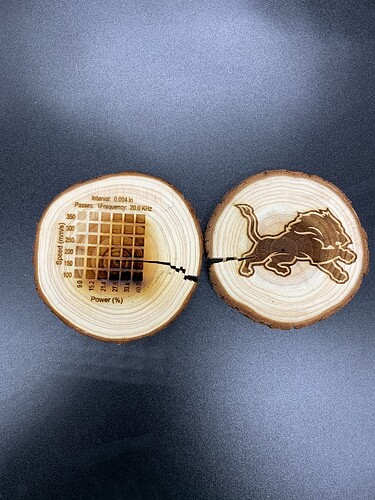

Any suggestions on how to get a darker image with a CO2 laser? It seems all it does is go deeper into the wood, but doesn’t darken it like my diode used to. The power grid is my CO2 and the Lions is my diode. To get the image that dark on CO2 I’d have to burn down very far into the wood so that the shadows create the darkness which is a dumb way to do it…

Anyone with experience here?

This is mostly going to be due to the nature of the lasers. Diode lasers are typically better about darkness and ability to have variable darkness.

Try defocusing the laser. This should make for a blunter focus dot resulting in more burn and less cut. This will be at the cost of reduced sharpness, unfortunately. You may need to increase power to compensate for the focus shift but will require experimentation.

I was worried that would be the solution… ok thank you

I would try coating the wood with bicarbonate of soda. Let it dry and run a test to get the correct setting. Different woods have different levels of sap and there will always be changes in the finished result. The details for making a bicarb coat should be searchable here on this forum. If not try YouTube for details.

That’s interesting, I remember hearing that now actually, OK thanks!

I think it’s a good example of…

driving a tack with a sledge hammer…

Are you running the same speed/power… I doubt it… ![]()

It doesn’t matter if you’re running a laser, 3d printer or a milling machine, all cnc machines need to have the proper speeds & feeds to do the most efficient job, with the least amount of energy. We call them a bit differently as the speed usually refers to the spindle (tool bit speed) and feed is how fast the surface speed is… or how fast the tool moves relative to the material. In some machines, both the tool and the material move.

For most tools being used for metals, the information is derived from a formula that tells the best speed & feed for a particular type bit used on a particular type of material.

One of the few programs I pay for, beside Lightburn, computes speeds and feeds for my little milling machine…

Most of these will do the job over a very wide range. You laser will cut at a wide variety of speeds (mm/s travel rate) and power.

Where it performs best is a small range of speeds & feeds compared to the range of where it will do the job.

The perfect range is more difficult with natural materials since they vary widely, as does the laser beam itself. This is not true with something like a milling machine where you know what you are using, diameter tools and number/size of teeth along with known material types and specifications.

Doesn’t matter if it’s additive machining such as 3d printing or subtractive machining with mills or lasers, the proper speed and feed will give the best results and the least wear on the machine and tool bit.

Lasers have their idiosyncrasies, such a frequency of the beam, spot size…

What is the lowest percentage power you can lase your tube?

If your led lasers output is 4W (probably generous) and you can only lase your tube at 10% pwm, then your output of an 80W CO2 is about 8W… twice what the led is putting into the material…

Have you adjusted your co2 down or speeds up enough to make up the difference…?

It just might be too powerful for your application.

When I replaced my so called 50W, I did so with a 40W tube… I enjoy the low power end which you can’t get with a high power tube.

![]()

This is the way.

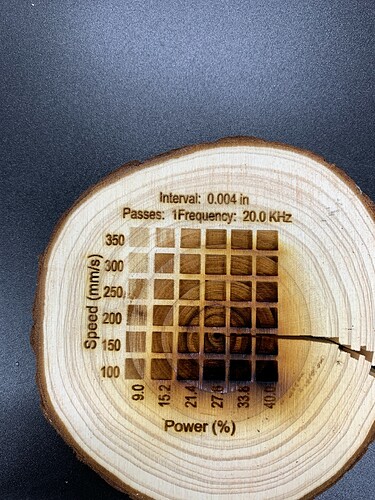

How could I? Completely different machines and I’m not sure how to even compute the equivalent. I just assume that a power grid provides the relevant info and from what I’m seeing nothing is even close. If I provide an array of powers and speeds, this should net me what is available, right?

9% or perhaps somewhere in the high 8’s

I’m sorry I don’t understand at all what you are referring to…

This is what the test grid does right?

As ever, thank you Jack

Sorry, not sure what you mean here

@bionicback321 was referring to the baking soda, I believe. That’s a common way to darken the wood… I never found it to be worth the effort, but my standards might be less.

What I was saying is that with your led machine, you have an output of about 4W. If you run 9% power with an 80W tube, that’s about 7.2W or almost twice as much power as the led laser.

If you run the same speed, which you can, it will create twice the damage to the material… than the led.

IMHO most run too fast with too high a power. Most of this requires less power and more speed…

You run into a problem when you use a machine that is substantially more powerful than the original led laser.

What kind of speed and power are you running (both lasers) and what kind of wood is it? Some wood damages more easily than others.

![]()

But that is the lowest I can go, 8-9% is the very lowest i can run, if I keep the power there, if I don’t increase the speed it will just burn through

Well, if I was to take a value from the test grid of the CO2 that I would consider not too penetrated … I would say 350mm/s x 21% power (again not being very dark) vs. my diode laser at 3200mm/min and 60% power

Yes, I was. My avatar is the Mandalorian, I was trying to be funny while agreeing with Ron.

Look at the difference…

The led is running about 53mm/s (have to convert) at about 60%, so if it’s 4W out, then you are using about 2.4W (60% of 4W) of output power at 53mm/s.

On the co2, you run 350mm/s at about 16W of output power. About 6 times the power with about 6 times the speed… These theoretically balance out as far as speed/power relationship go. So you did the right changes to make it relatively equal.

As you know the tolerance of a material to heat will change as you give it more heat and less time…they are rarely linear. It usually isn’t a direct relationship or we could easily compute it.

You are giving it a lot less time to make up for a lot more intense heat in a relatively short period… This is probably where your variation comes from.

Add in the other variable, such as laser frequency and they are not directly comparable.

The problem you run into, is if you want to control the machine, you have to keep the speeds down were the lps can respond properly, at that point, you’d probably sizzle the wood…

Again, I picked the 40W tube over the 50W, because I have more low end control of the power… The led will have a different effect on wood because of the different frequency…

I think your only shot, is to use an additive to help darken the results or do a lot of fiddling around to see if some value will give you the desired darkness without the extra damage.

If you are getting correct dark from the materials test, that should be reproducible.

May be a good enough reason to break out the led… ![]()

The right tool for the right job.

Good luck… I’ll be following.

![]()

Great analysis, as ever thank you for taking the time. I will try the baking soda method and post results.

Suggest also experimenting with borax. Baking soda can discolor the wood and that may or may not be what you want. Borax from what I saw did not do that. Borax gives a blacker engraving, baking soda more of a dark brown.

Can’t recall on baking soda but borax will leave almost an ash like finish that is easily disturbed and will rub off. Unless you plan to seal the finished work in some way or it’s otherwise not going to be handled, may not be the best choice.

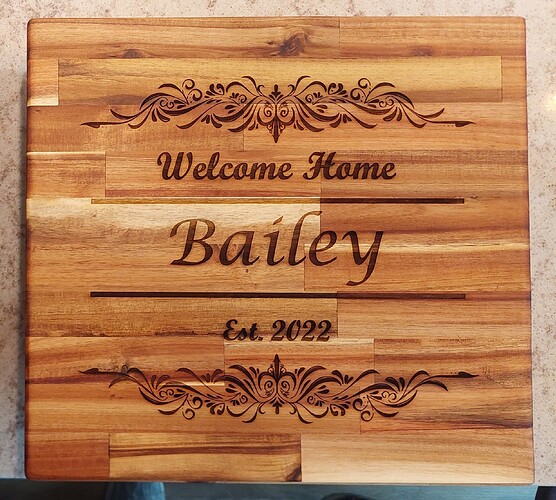

Right or wrong I’ve avoided using borax (I don’t want to open that can of worms) because most of what I do comes in contact with food. I’ve engraved some 20 plus of these cutting boards (for a local realtor) over the last ten months, first with my 5.5w Ortur diode laser (which helped pay for a 50w OMTECH), so I too was concerned about the quality of the finished product when I started using the CO2 laser. I can see the difference in the areas where the wood is lighter, but the mineral oil I use after engraving helps to make it less noticeable. You can see it in the horizontal bars above each of the names (Kristin is diode, Bailey is CO2). My clients haven’t complained and 45 min. sure beats 1.5 hours for engrave times. I use Acacia butcher block countertops from a local hardware store, and I’ve found a setting that gives me results that are fairly close to what I was getting with the diode laser. Picking the darkest piece of wood has been key for me.

This is also great info that has helped, thank you!

The one thing that helped me the most was after engraving a design with the diode laser (a 4X4 Acacia coaster) I kept repeating it on the CO2 laser until I got the same level of darkness. In my case it was 250mm/s @ 35%. The design was small enough that it could be repeated very quickly. And every four that I did I had another set I could either sell or give away. Just my 2 cents worth.

From my experience it is also a question of power. If too high power is used, the wood is more “evaporating” instead of burning. Try to use lower power and adjust the speed. You need to play with power and speed.

Thanks for your response. I guess there’s just a point where I’m like why bother wasting time on my CO2 if I need to slow it down that much, when I can just use the diode. I mean I’d love to use the CO2 for everything but from what I can tell the useable life of the CO2 tube is much much less than the diode.