The wires don’t look hooked up

that was after the wires were connected

i was testing the system to see what error came up, so disconnected wires

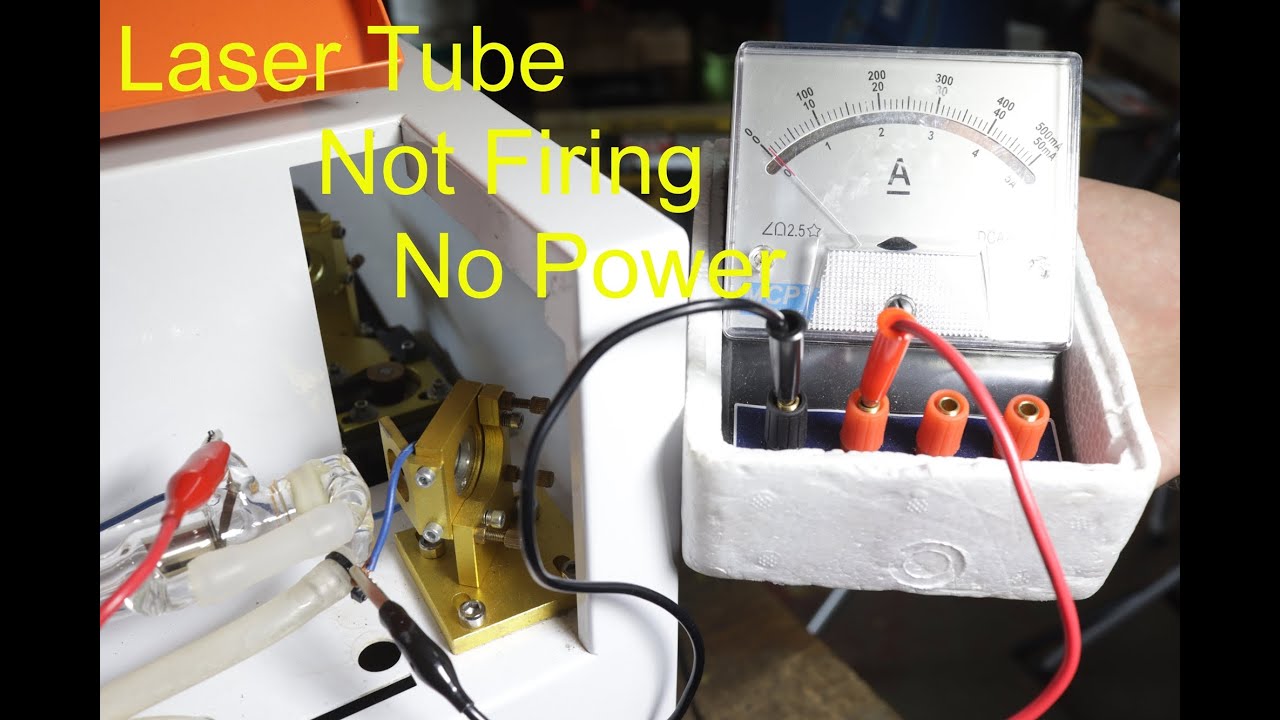

youtube has many videos with people that have the same or similar problem, so far havent found any that fit my circumstance, so hoping someone in the Lightburn world knows how to fix my problem… Sam

How is the sensor wired? Can you take a photo of your LPS wiring?

Probably as we’ve stated you do not want a flow meter, in reality it’s a pressure switch.

The photos look like what you want, do you have a ohm meter to check the continuity?

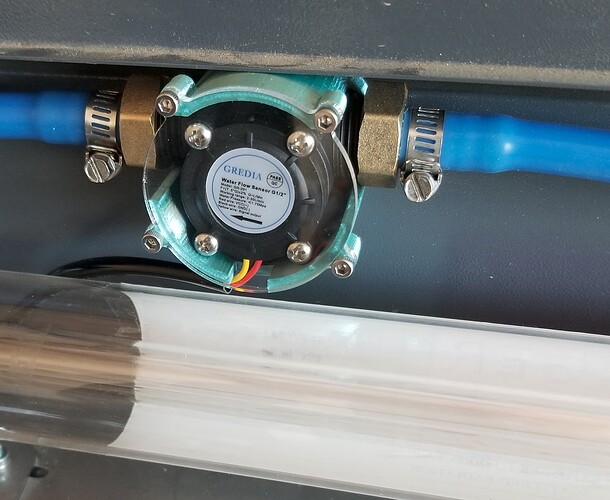

Are these sensitive to flow direction? It would be a bummer is you, by chance, installed them backwards… I would hope they would be marked if that was an issue… do you have a purchase link, so I can read about the ones you have…

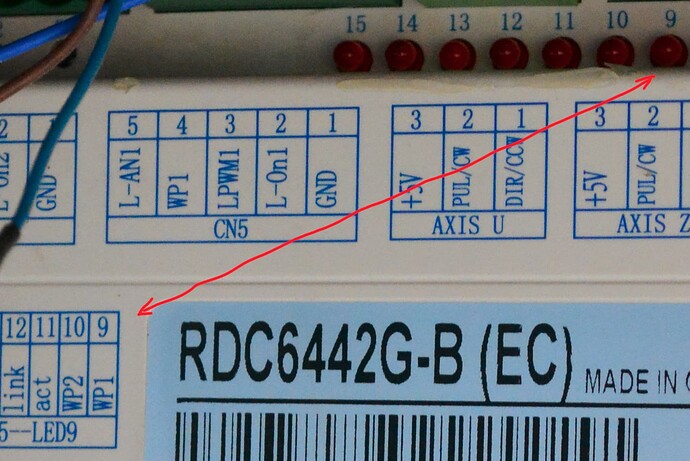

The diagnostic panel show’s what the Ruida is ‘seeing’ If it was ‘stuck’ active, then the machine would not give you a wp fault and would not ‘partially’ run.

I can speculate, but that’s it. If you can measure it, that would be good.

If I were there, I would do this as a diagnostic. Anytime you run something with the protection systems disabled, those ‘safeties’ are now the diagnosticians liability.

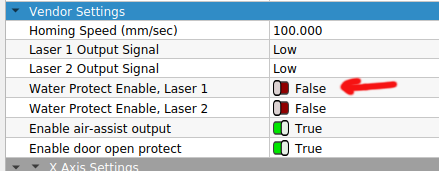

I am suggesting you go into the Ruida control panel and disable the wp inputs. The Ruida will ignore them and you can attempt a job. If it works uninterrupted I’d guess that you have a wp switch issue. If it fails with a wp error, it would suggest a controller problem.

Can you confirm that the P input of your lps is wired to ground?

![]()

there are only two wires on the flow meter, I am told by reputable people in the laser industry it doesn’t matter which way they are connected, the Ruida panel only gives me a message on the problem, not a code to follow up, even if it did i don’t know how to progress on this panel, I don’t have any book to look up faults on Ruida, any suggestions, how do I disable the WP inputs on Ruida. how important is the earthing cable on the machine, does it need screwing to the concrete or just attached to the bench? whats your background you sound like a tech guy in the computer industry. Cheers Sam

I am not speaking about the wires, I am speaking about which way the coolant is flowing through the sensor.

Edit → Machine Settings → Vendor Settings

Mine is disabled here, it will ignore the wp signals.

After you change it, you must ‘write’ it back to the controller.

You should make a backup of the original settings before you change anything…

Generally they have a ‘flow’ direction if it is needed, on the switch somewhere. This is an actual flow meter, notice the black arrow…?

![]()

Do this at your own discretion. But if it were me I’d twist the wires together at the switch that go to the controller and see if it works. That way it would rule out the controller and wiring going to the controller.

The problem is that it runs then quits with a wp error. The diagnostic display shows the wp as active. It didn’t show ‘inactive’ if I recall.

Trying to discern if the new wp switch is causing it or if it’s elsewhere.

It has other issues also, but … get it to where it works then we can work on other issues.

![]()

If it’s the switch or an actual water flow issue the problem would be temporarily disabled and not via the software.

the switch has an arrow for direction , simple, its in the right direction

found an interesting article on youtube www.coletoolcentre.com.au about water flow metres, also mwlaser.com.au

Good that’s it’s correctly installed in the flow direction.

Did you state that the Ruida always show an active wp signal in the diagnostic panel, even when the coolant is off?

Youtube is pretty ‘big’, a link is always nice…

![]()

simple things always baffle people.

With this stuff, it’s exactly right or it doesn’t exactly work… ![]()

![]()

Not following here. If the Ruida detects a failure, it should stop the machine until you corrected it and let it continue.

I would like him to ensure he has water flow, disable the sensor and run a job. He is the one that’s responsible for ensure it will not have a coolant issue during the ‘short’ job run. See if it runs to completion or not.

It would make this easier if you can answer:

- does the flow switch in the diagnostic screen show the switch active with flow and not active without flow?

- Is your lps P terminal tied to ground?

![]()

It will mechanically disable the sensor without the setting the Ruida to disable. Basically make the controller think everything’s ok. Temporarily

Thoughts were to prove it’s not a wiring or controller issue.

That’s the idea. His description when it works/doesn’t with a wp error indicates an intermittent on that input. If it faults, we know it’s probably a controller issue

The P terminal is probably not in question and is grounded. If that was used the Ruida wouldn’t stop.

But it would be nice to know if it’s ‘sees’ the proper signal on the consoles diagnostic screen.

If you notice on my picture of the diagnostic panel my wp are both set to off.

I had a problem with it not detecting the chiller being off. If I look at the diagnostic panel the Ruida reads the wp 1 as active, when it is not.

A quick check of the hardware led 9 showed it was getting the right signal to it’s input as it responded properly to the coolant on or off.

Never use the ‘door open’, so I moved it to that input. Not going to by another controller over that…

![]()

Hi, Guys further update. tried the settings on Ruida to check water protection, using light burn Machine settings, but nowhere on this program does it show me Water protect to enable or disable, so returned to my laptop to send the test program to laser, and laser accepted the program but could not frame, as the laser is set now in top right-hand corner and will not let me change coordinates. so manually moved laser to center of the machine and tried to pulse, this works fine, pulse working. opened the door and tried pulse not firing, shut the door and tried pulse Firing, so we know the door open won’t let the laser fire. sent laser back to homing position top RH corner and tried again to send a test, fired start and beeper started laser would not fire. we now know the laser will fire, but won’t accept a test cut…any ideas… Sam