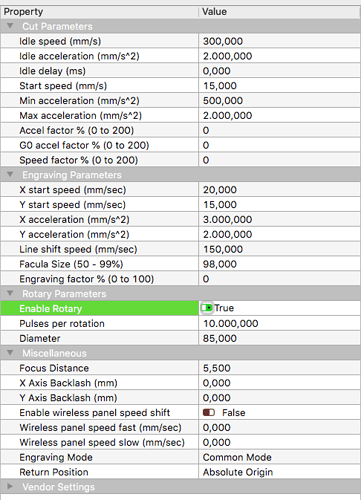

The diameter I don’t think matters for the initial setup. I don’t think you completely understand what you are setting up.

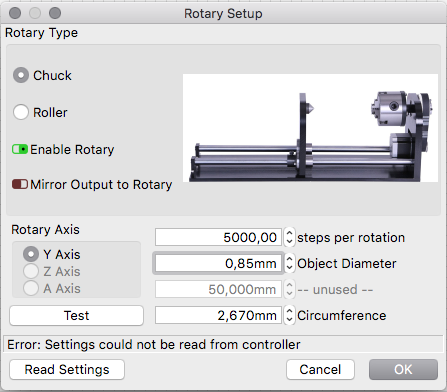

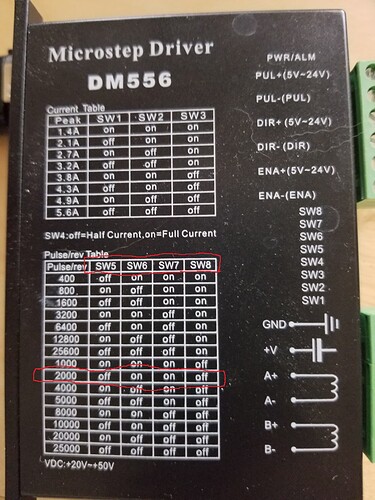

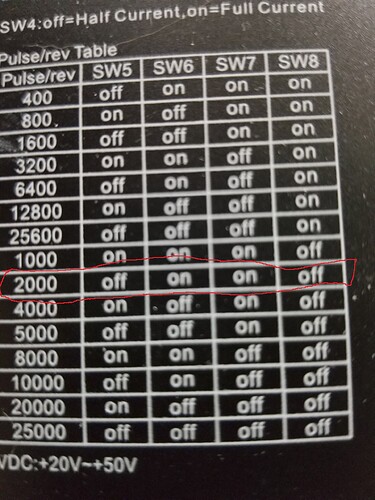

To get to here you only need the steps for the motor to make 1 turn and the ratio. Assuming the correct motor, it should be the 5,000 steps as setup on the driver. You need to find the rotary, which I have no clue about yet and determine the gear ratio, if it has one. Since you came up with 10,000 steps and it worked with RDWorks, I hope you find it is 2 to 1. You need to be certain.

Lets talk about how a rotary works. It, in effect is now the Y axes. So the ‘surface speed’ of the object needs to be known (or computed) for the machine to ‘drive it’ like the Y axes ‘surface speed’.

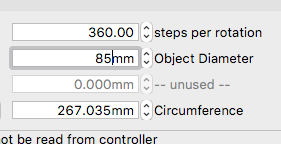

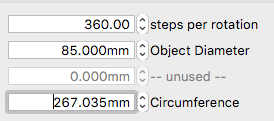

On a ‘wheeled’ rotary the end product is one rotation of the driving wheel. When the software knows the diameter of the driving wheel, it can compute the wheels ‘surface speed’ which will be equal to the surface speed of whatever object you place on it. Once the setup is done there is no need to adjust any of these values.

On a ‘Chuck’, once you have it turning the ‘chuck’ once for the number of steps, you have to give the software the diameter or radius of the object so it can compute the ‘surface speed’ or how fast the Y axis needs to move. This must be done for any variation in the objects diameter.

As you can imagine a 50 foot diameter object would have a much higher surface speed to make 1 rotation that a pencil. This is where you need to know the diameter.

Not so with a wheeled rotary as the surface speed of the wheel will be equal to the surface speed of a mounted object since it’s driving it directly.

At this point, lets get the rotary acting properly.

Your setup should allow the ‘test’ button to rotate it one complete turn and then return to the start position.

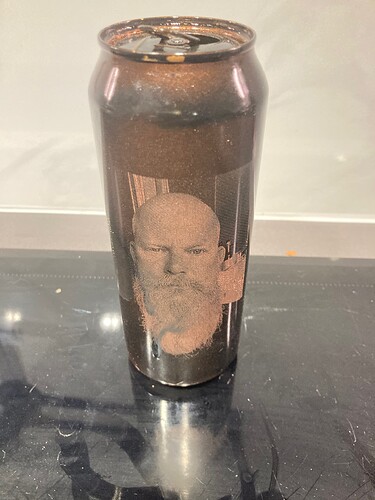

What is concerning is that you get no difference between numbers…

Once we know all the data is correct we can chase down what else maybe configured incorrectly.

Make sense?

My Ruida homes on power up and there is no homing switches on rotaries, so it will fail to home if the rotary is plugged in when it re-boots.

Could you include a link to the rotary you have?

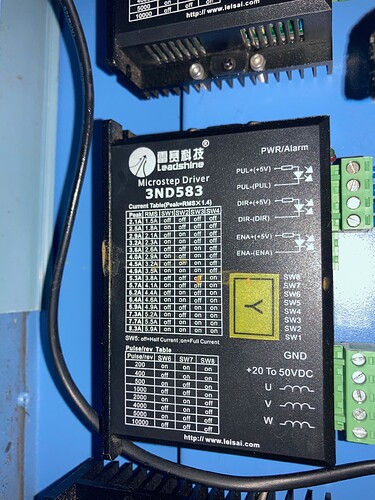

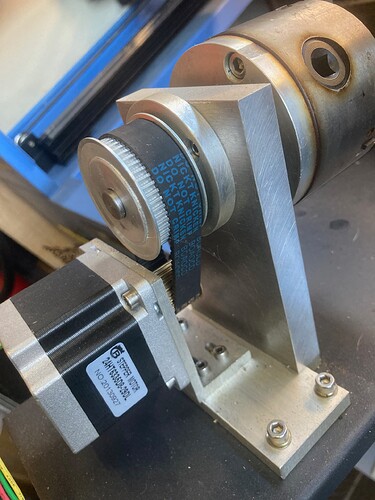

Noticed yours is a three phase motor, mine is two phased…