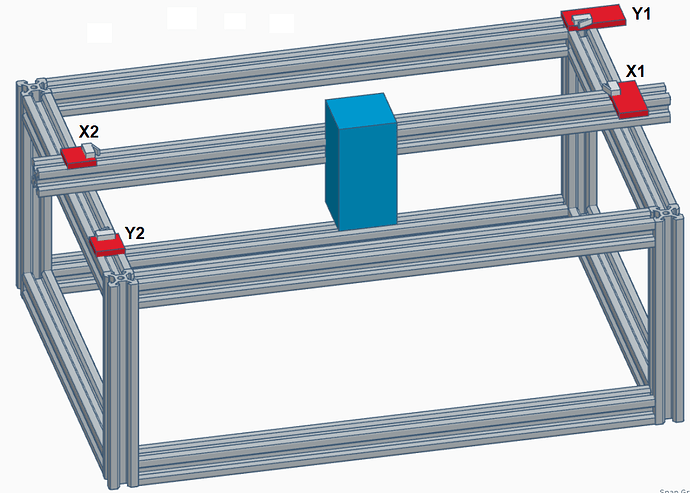

My laser is equipped with limit switches on the X & Y axis for homing the laser to the back right corner. Every once in a great while, I manually move the head to check something and forget to home the head, & as a result, the head crashes into the front or the left, grinding the steppers.

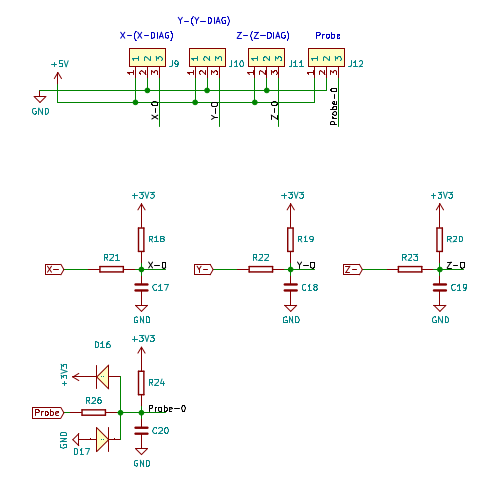

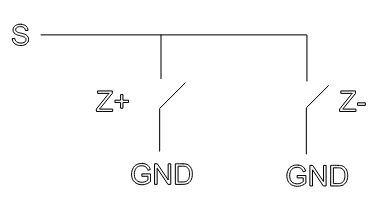

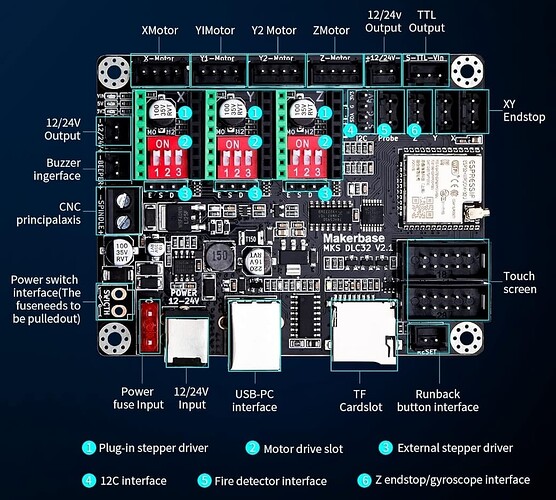

I’m using the Makerbase DLC32 v2.1 controller, & came up with my own design for adding two additional limit switches connected to the unused Z limit switch input of the DLC32. Due to how limit switches work, two of them can’t be connected in series or parallel.

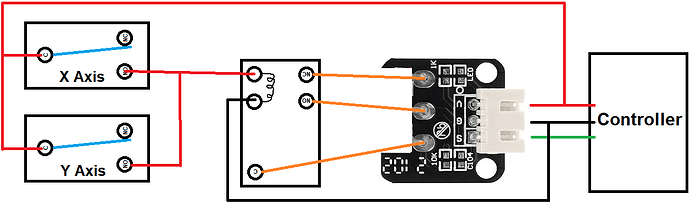

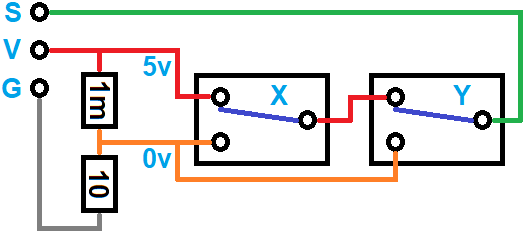

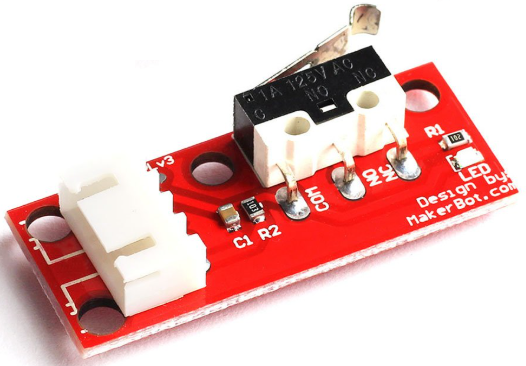

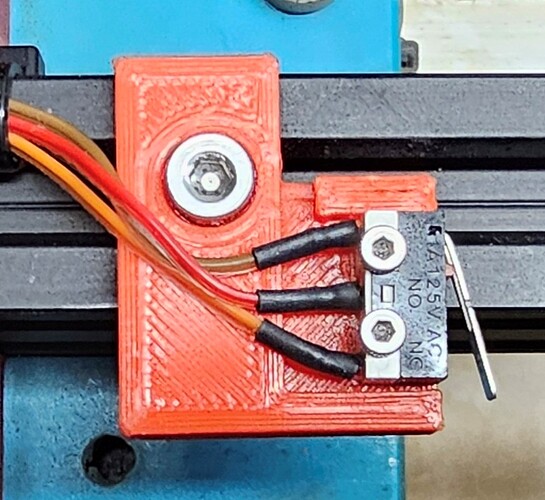

What I did was mount two micro switches in parallel that control a 5 volt SPDT relay. I removed the microswitch from a limit switch circuit board I already had, and connected the Common, NO, and NC of the relay to the corresponding microswitch points on the limit switch circuit board.

Since these limit switches will rarely be hit, I decided to use the “normally open” contacts of the microswitches so that the relay wouldn’t be “energized” for many hours on end, waiting to be useful. I figure it would extend the life of the relay by going this route. When either microswitch is hit, it sends 5 volts to the relay which in turns provides the proper input to the limit switch circuit board.

Can anyone offer a more “elegant” solution that might eliminate the relay and cannibalized limit switch? I did some experimenting with “pull up” and “pull down” resistors but couldn’t come up with a circuit that would work.

Thanks!