Hi all,

Thanks for all the comments and suggestions.

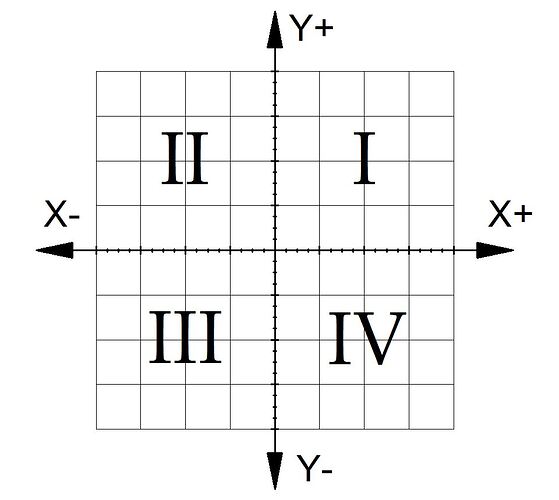

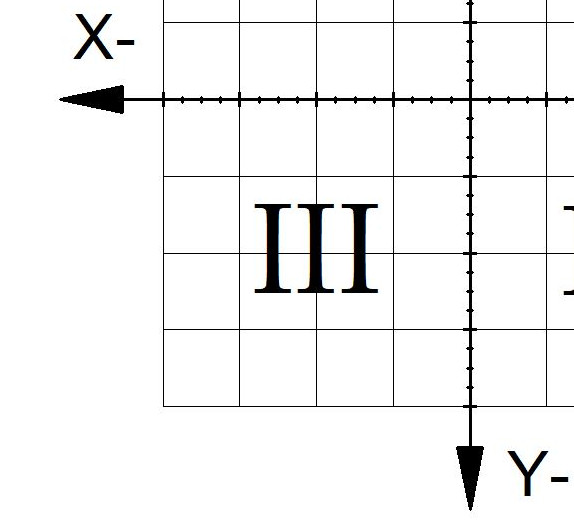

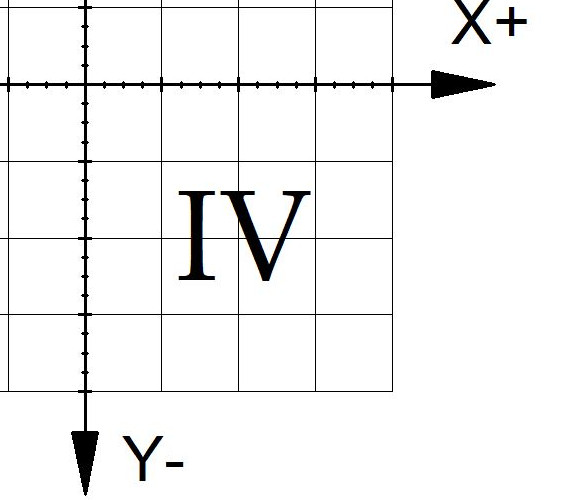

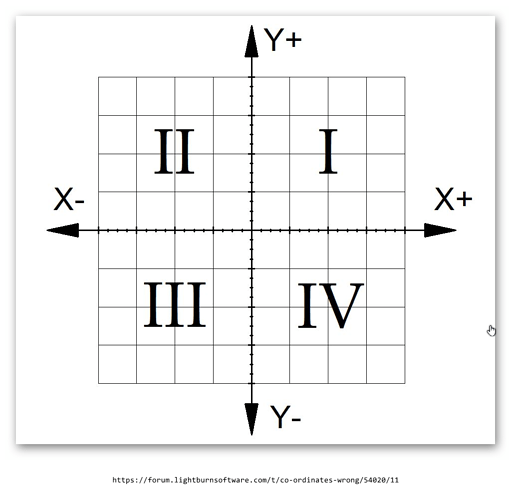

OK, I’m fully aware of the positive and negative values as per this chart (JKWilborn). Good to have it reinforced in the grey cells.

So I am assuming that the workbench (table) is

close to me and to the left of the table?

OR

Is it far away from me with the and to the left of the table?

I have always assumed that the LightBurn work zone just slides down towards me as a flat surface and is the table nearest me?

Hope that makes sense.

Well anyway.

OK on the Macro (done) (Thanks berainlb).

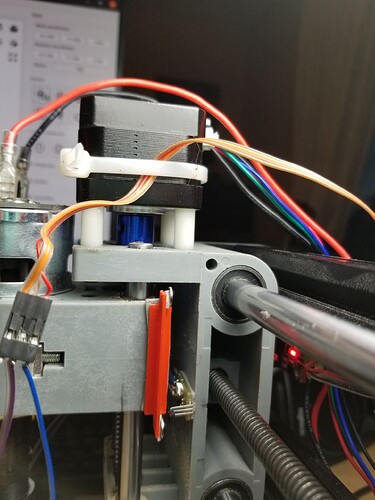

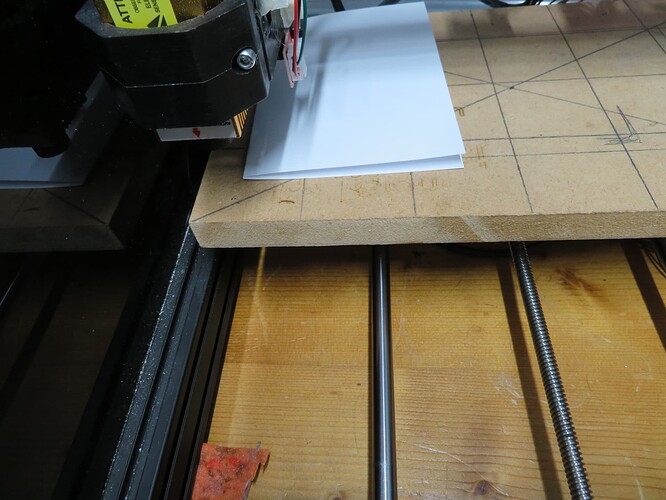

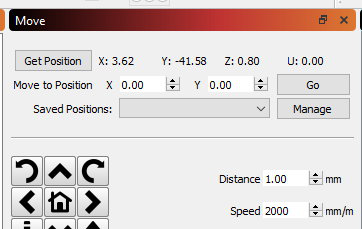

The next observation is the picture I sent… below

Right, This is what I did:

*** switched off CNC 3018, removed power and USB data lead.**

*** Closed down LightBurn and closed down the computer.**

*** Went for my evening meal. At least an hour with everything off.**

*** Booted computer**

*** Replugged CNC3018 USB and power.**

*** Started CNC 3018**

*** I Started LightBurn gave it 15 seconds in case it was busy in the background.**

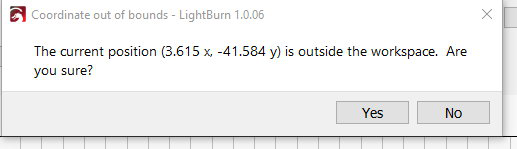

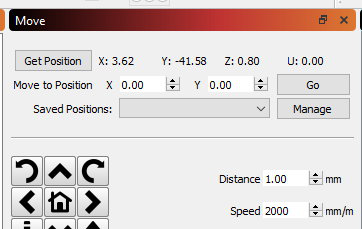

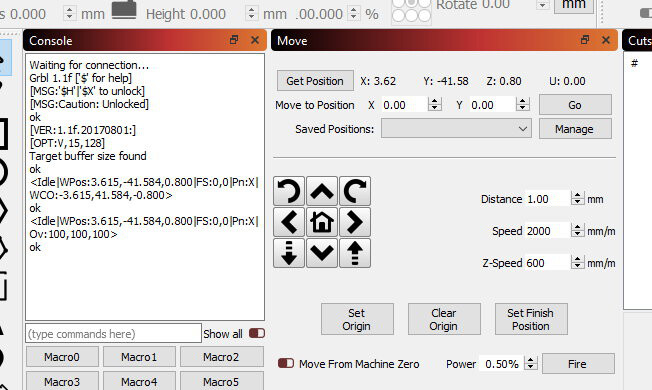

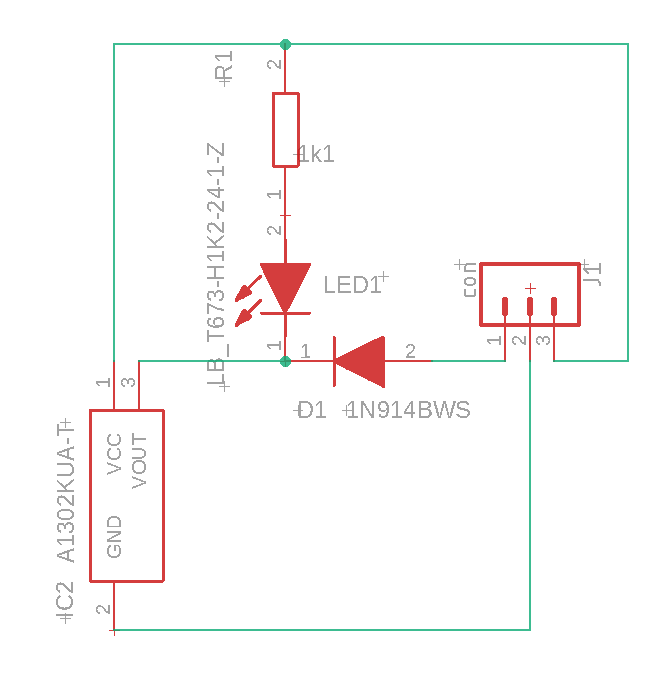

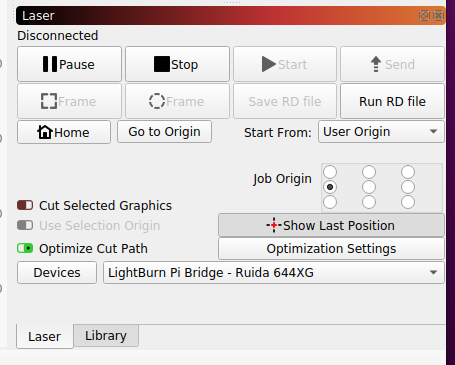

*** Pressed the Get position button, this is what I got.**

Everything has been reset, but on power-up and Get position today, those are the exact same readings.

The worktable is full to the front and laser over the rear corner of the worktable.

I can’t remember what the settings came up as on the previous controller, but they were different and never zero.

If I do the G92 X0 Y0 then Get Position it, sure enough, shows Zero.for X & Y But on boot up, it’s wrong again.

While writing this I’ve been doing some tests. All I seem to be doing is getting deeper into trouble.

Like now I have an ALARM 2

<Idle|WPos:3.615,-46.584,0.800|FS:0,0|Pn:XYZ|WCO:-3.615,41.584,-0.800>

ok

Starting stream

Layer C00

ALARM:2

G-code motion target exceeds machine travel. Machine position safely retained. Alarm may be unlocked. (Right-click the ‘Devices’ button to reset the connection)

On or near line 2:

Job halted

Stream completed in 0:00

[MSG:Reset to continue]

ok

Grbl 1.1f [’$’ for help]

[MSG:’$H’|’$X’ to unlock]

[MSG:Caution: Unlocked]

ok

<Idle|WPos:3.615,-46.584,0.800|FS:0,0|Pn:XYZ|WCO:-3.615,41.584,-0.800>

ok

Starting stream

Stream completed in 0:00

<Idle|WPos:0.000,0.000,0.800|FS:0,0|Pn:XYZ|WCO:0.000,-5.000,-0.800>

ok

Is there a command for a total reset out of the box state?

I think I need to do that if there is.

Regards

Kevin (the confused)