When I suggested it may not be 100w, the thought is, that it is not putting out 100w. for whatever reason.

Ah ok, and what could be the reasons for the 100W not getting out ?

But I think, my focus lens problem is now my main one…

- Early tube failure.

- Poor connection/s between tube and poor supply.

- Power supply issues

- Grounding issues.

2 items: Do a ramp test to get your focal length( google " laser ramp test" ).

Next, there were a few people with chinese laser cutters in these LightBurn forums which ended up with the laser power supply wired up incorrectly so it was not being PWM power control.

Good idea Doug.

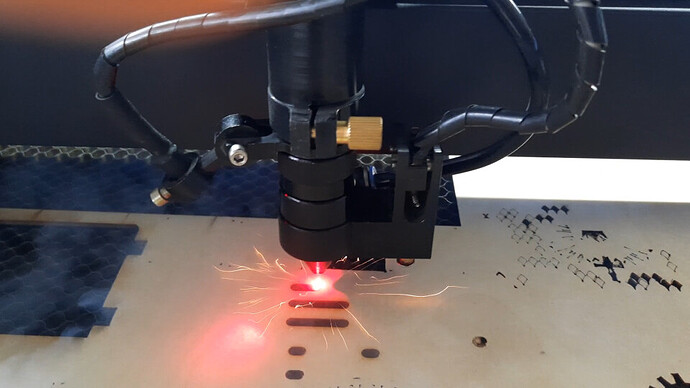

But first I have to solve my new problem with the not focused laser beam. As you can see, this dioesn’t look very nice:

Maybe the lens is wrong sided ? I put it flat side down (to the wood) and tried the other way also, same problem. Maybe trashed ? But it looks ok, no scratches or so.

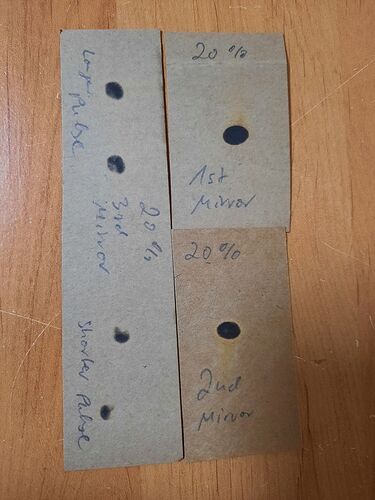

What does burn shape look like at each of the mirrors if you pulse the laser ( low power ) ?

The “ramp test” is how you troubleshoot your focus problem. It not only shows you where your focal point is, by how wide the marked line is at the focal point will point out your lens or mirror issues too. For a CO2 laser your focused beam should be less than 1mm and more like less than .5mm.

From the beam size in the squares above, I see a problem that goes beyond focusing at the lens.

I’ve never seen a beam size that big on any ramp test I have run.

It’s like there is no lens at all.

That’s what I thought. Can that lens fit in more than one position in that tube (different heights?)

Looks quite big…

The lens is sitting in a tube which is sticked and tightened in another tube on the laser head. You could tigthen it in a lower position, but it was the full way up before. Strangely, when you do that, the autofocus doesn’t work anymore although it’s fixed on the tube and goes down together with it.

Would it really make a difference ? Because the laser doesn’t care how far the lens is, otherwise you would have problems while the head goes back and forth or even with different table sizes, right ?

What I was curious about is if the lens can be fitted in a position so far up the tube where the focal point is way up inside the tube so impossible to focus correctly.

A cloudray C-type head has several possible lens locations, just wondered if yours did too.

No, there’s only one fixed place for the lens in the tube.

that looks like the laser beam is 1 cm in diameter at the first mirror. FAIL. Should be closer to 3 or 4 mm.

I also don’t get how you go from this cutting to those big fat blobs… Cut through plywood is inconsistent - #11 by skippy

There are 2 problems in this thread. A) Inconsistent cutting, before I reconfigured the laserpath and B) now the big fat laser beam after that.

So I have a new problem now and have to solve this first and then look after the first one.

I must have missed where you stated you’d messed up the mirror alignment. There are dozens of instructions and instructional videos online which cover beam/mirror alignment and cleaning.

Yes, and I did align the mirrors. Then I took out the lens and cleaned it, put it back again. That’s it. And then this result. I have no idea what could have gone wrong. The only thing could be putting the lens wrong side in, but I changed it and tried the other way round, still the same.

On the first mirror it is 10mm x 7mm

What about the sprinkling laser flashes in the picture with the laser head ? That was not there before, has anybody seen something like this ?

I don’t know how you cleaned the mirrors and lens but it has to be done delicately and carefully. I’ve seen people use tape in front of mirrors to do alignments and that’s a big mistake. it sprays molten glue all over the mirror behind it… I’ve seen people use Q-tips and rub back and forth but that to is wrong. only circular motion and while rotating the tip one revolution and only one revolution. Otherwise debris becomes a scouring pad and scratches the mirror. If you did a cleaning and alignment and it got worst then something was done incorrectly.

Alignment I do with tape on the frames before the mirror. For the lens I used a lens cleaning fluid with a lens cleaning fabric, and of course carefully but not in circles.