Hi, could any one of you help me recommend me the best Power / Speed combination for cutting on 6mm MDF, I have been trying in different values in many different tests, and I just can’t have any cut. Thank You.

Sorry, but it can not be done with a normal diode laser.

It requires approx. 40 to 60 watt laser power.

Of course you can try to set your laser to 100% and 45 passes, maybe you will get through 6mm MDF, but the result will not be usable (with a 5.5W diode laser).

Hi, Thank you, Bernard, I did many tests with no results, apparently, I have the wrong lasser.

Thks.

MV

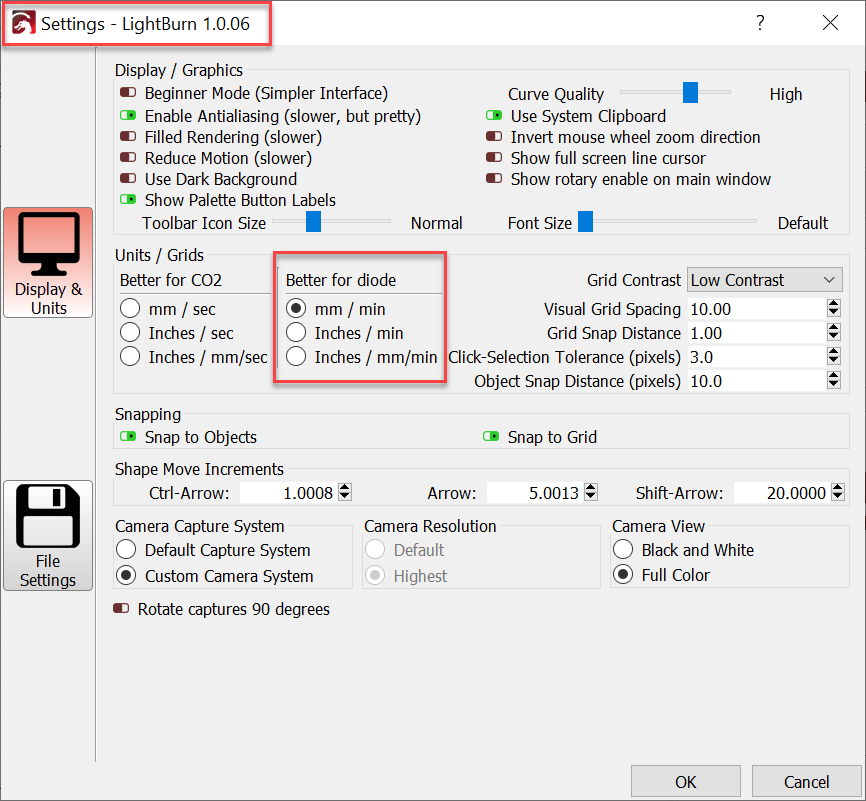

It may be possible that you have a units setting (particularly the speed setting) set up in a way to create no results. Please check to see if you are working in mm/min and that your laser is making a groove in the MDF.

What speed are you testing at? …and what are the units of speed being communicated?

What kind of diode laser are you running? I just made an air assist nozzle for my sculpfun S9 and i"m cutting through 7/16" solid cherry with a 5.5W. Its still several passes i think 30 passes at 7.63mm/s. I don’t have a piece of MDF to try but cherry is harder than that.

When you say harder do you mean that it’s physically a harder material or harder to burn? I’ve found MDF to be rather challenging. I assume it’s from the binders used to create the material and the overall density. I personally hate burning it. The residues are awful.

By the way, getting through 7/16" of any wood with a diode is pretty impressive.

yes physically harder, probably burns less as well due to grain structure. Iwas temped to see if i could push it. I came up with the idea of trying to make the nozzle for it and working on round 2 as we speak. Round 2 will have a smaller diameter hole going through and a finer point to it. I made the opening on the first nozzle 1/8" incase the beam from the lens started out bigger, but its tiny. I think the spot compression in the S9 or any of the diodes makes a huge difference in cutting. and the engraving is pin point perfect.